A kind of preparation method of silk fibroin thixotropic gel

A technology of silk fibroin and thixotropy, which is applied in prosthetics, medical science, etc., can solve the problems of not being able to load protein active molecules and the impact of biocompatibility, and achieve increased work efficiency, no pollution to the environment, and simple follow-up operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

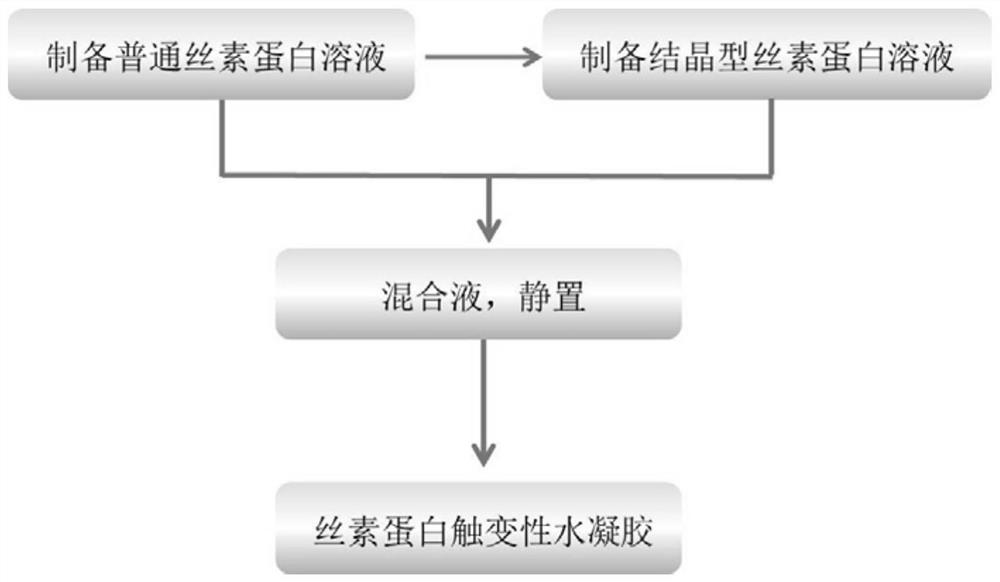

Method used

Image

Examples

Embodiment 1

[0027] Prepare silk fibroin solution. Specifically: put 60g silk in 0.02M Na 2 CO 3 Boil in the solution at 100°C for 30 minutes to remove sericin on the outside of the silk, rinse with deionized water, repeat the above operation 3 times, and then dry the silk at 60°C. 30 g of the degummed silk after the above treatment was weighed and dissolved in 100 mL of LiBr solution with a concentration of 9.3 mol / L, and dissolved at 60° C. for 4 hours. Then use a dialysis bag with a molecular weight cut-off of 3500 to soak in deionized water for dialysis for 3 days, during which the water is changed every two hours to remove LiBr in the solution, thereby obtaining a pure silk fibroin solution.

[0028] The pH of the silk fibroin solution was adjusted to around 4.0 with dilute hydrochloric acid, diluted to 1% with deionized water, placed in an oven for 24 hours, and then ultrasonicated for 30 seconds with an ultrasonic cell disruptor to obtain a crystalline silk fibroin solution.

[0...

Embodiment 2

[0032] The pure silk fibroin solution was prepared by the same method as in Example 1.

[0033] After the silk fibroin solution was concentrated at 60° C. for 48 hours, it was diluted to 1% with deionized water, placed in an oven for 24 hours, and then ultrasonicated for 30 seconds with an ultrasonic cell disruptor to obtain a crystalline silk fibroin solution.

[0034] Dilute the ordinary silk fibroin solution to 1%, and then mix it with the above silk fibroin nanofiber solution at a volume ratio of 1:10 at room temperature, and obtain a silk fibroin thixotropic gel after 1 hour.

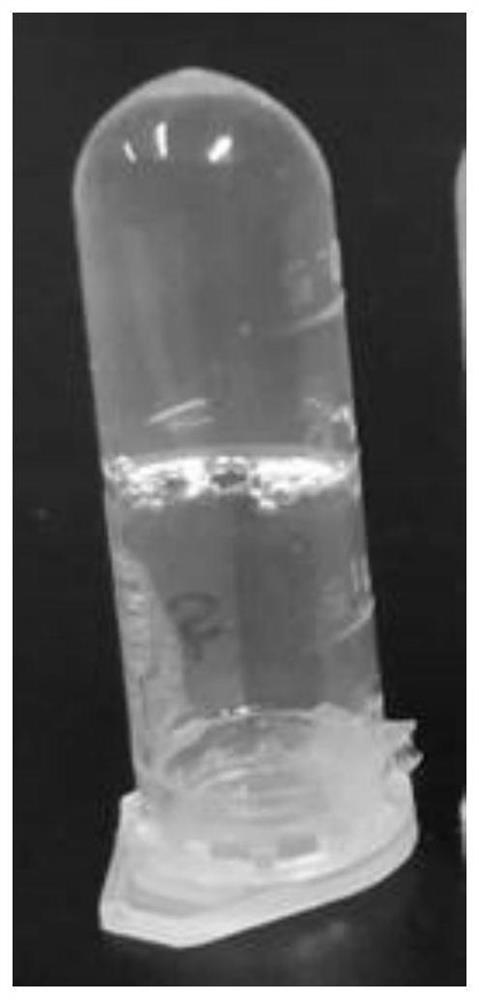

[0035] See figure 2 , figure 2 It is an optical image of the silk fibroin thixotropic gel described in Example 1. From figure 2 It can be seen that the gel has a very high transparency.

Embodiment 3

[0037] The pure silk fibroin solution and the silk fibroin nanofiber solution were prepared by the same method as in Example 2.

[0038] Dilute the ordinary silk fibroin solution to 1.5%, then mix it with the above silk fibroin nanofiber solution at a volume ratio of 90:1, let it stand at 0°C, and obtain a silk fibroin thixotropic gel after 96 hours .

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com