Punching device for handmade leather manufacturing

A punching device and leather technology, applied in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problem of high cost of use and punching The number of devices is large, time-consuming and labor-intensive, etc., to improve work efficiency, realize adaptive punching design, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

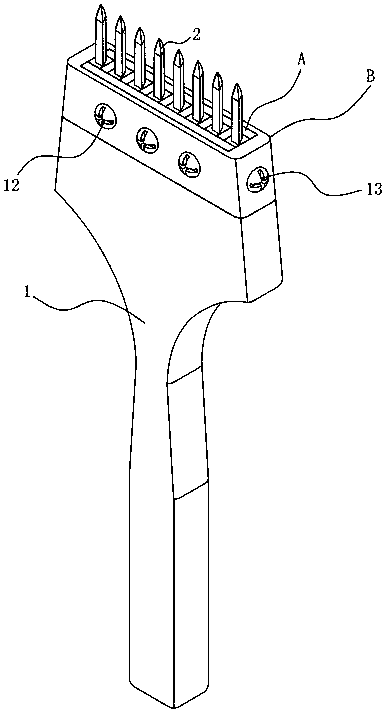

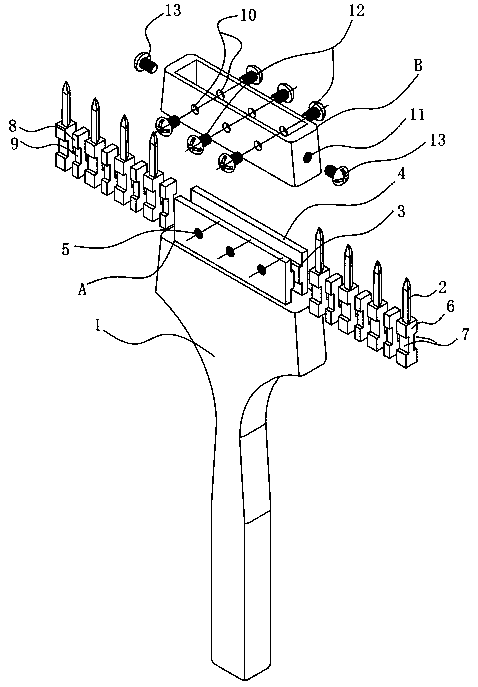

[0020] See attached Figures 1 to 6 , the punching device for handmade leather in the figure includes a knocking handle 1 and a hole-shaped mold 2 located at the head position of the knocking handle 1; wherein: the head position of the knocking handle 1 is symmetrically arranged with Two slide rails 3, the two slide rails 3 are respectively fixed on two fixing plates 4, and longitudinal positioning holes I5 are arranged on the fixing plates 4; the two fixing plates 4 integrally form a hole-shaped mold positioning structure A;

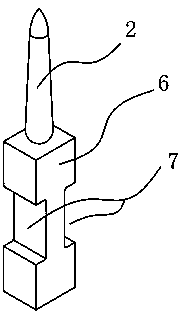

[0021] The hole-shaped mold 2 is arranged on the slide block 6, and the front plate surface and the rear plate surface of the slide block 6 are provided with chute I7 matched with the slide rail 3, and at least two Hole mold 2;

[0022] At least one spacing adjustment block 8 is arranged between two adjacent hole-shaped molds 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com