Self-absorbing sports plastic floor capable of preventing temperature difference deformation after being assembled

A plastic floor, self-absorbing technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of small temperature difference deformation of joints, temperature difference deformation, affecting the use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

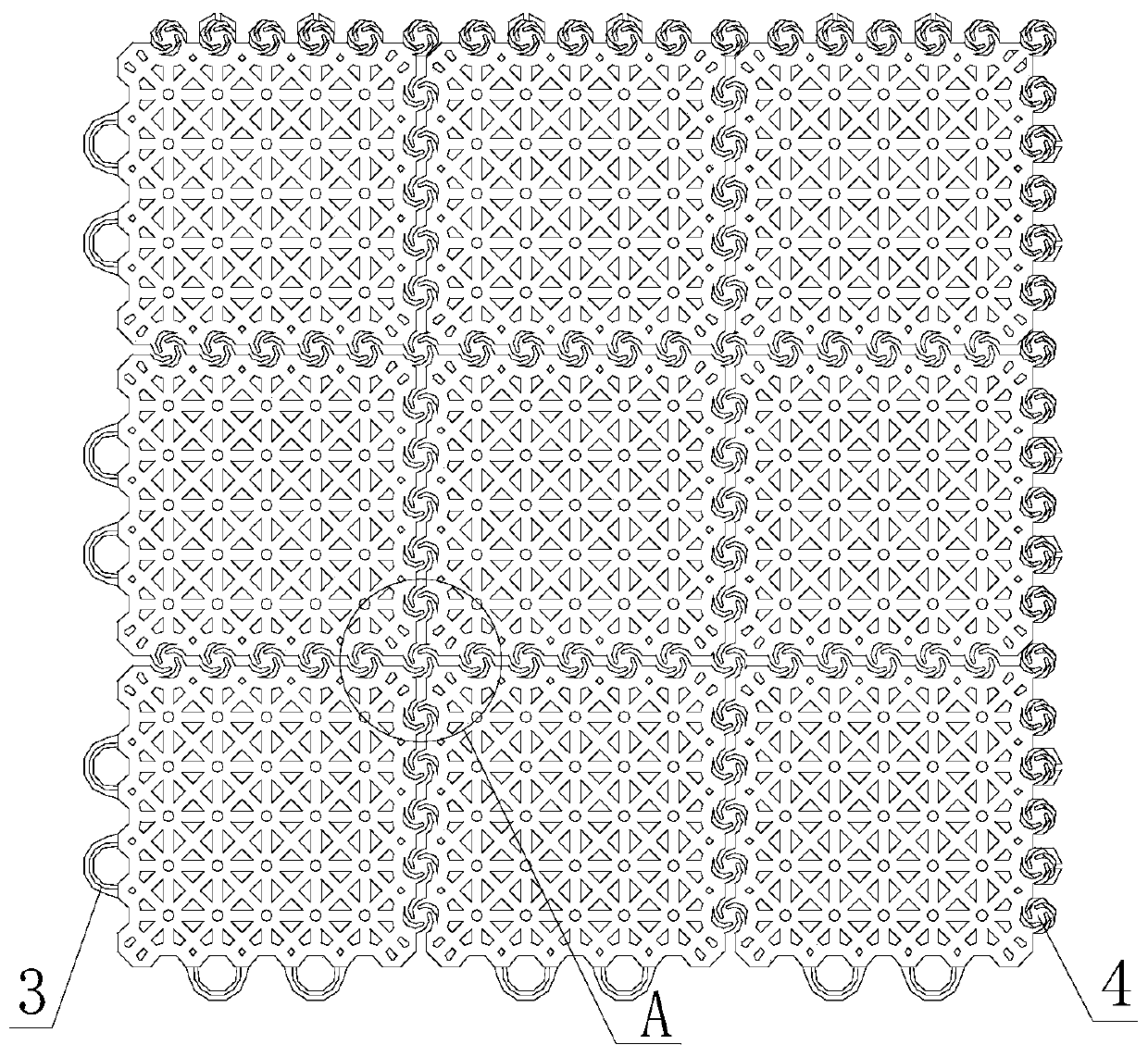

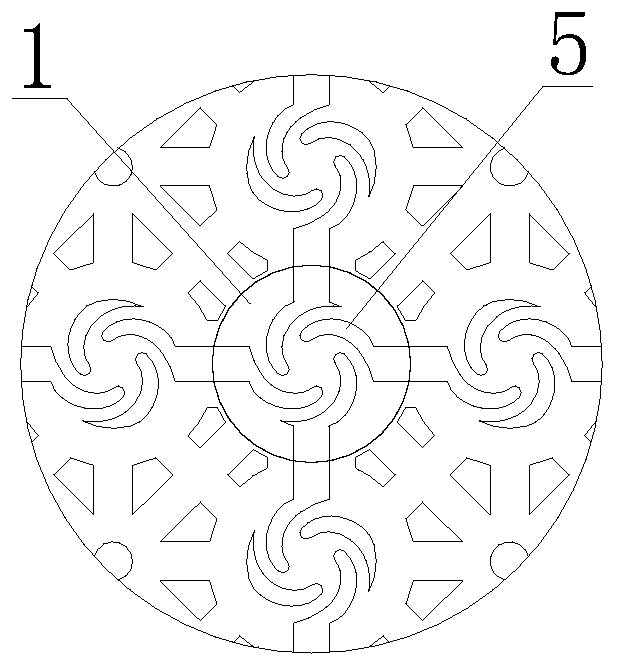

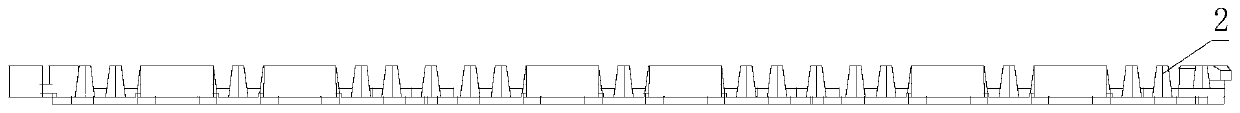

[0014] figure 1 with figure 2 The schematic diagram of the distribution of the deformation holes of the plastic floor plate of the present invention and the local enlarged structure are shown. The connecting ring 3 and the connecting column 4 provided on the side wall of the spliced plastic floor plate and the floor plate are assembled in pairs in the present invention. The two adjacent sides of the plastic floor plate are set, the connecting columns are set on the other two adjacent sides, and the connecting ring wall is corrugated or zigzag. The innovation point is that the floor plate is distributed vertically and horizontally. The hollow helix is composed of 5 sections, and the extended hollow parts of two adjacent hollow helixes are connected to form an expansion space for deformation due to temperature difference. Floor plate support columns 2 are arranged on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com