Inner flow channel supporting structure of small-medium-sized gas turbine exhaust cylinder

A technology for gas turbines and support structures, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as tearing flow channels, high-temperature gas disturbance, excessive stress deformation, etc., to reduce working thermal stress and working temperature , the effect of preventing deformation and tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

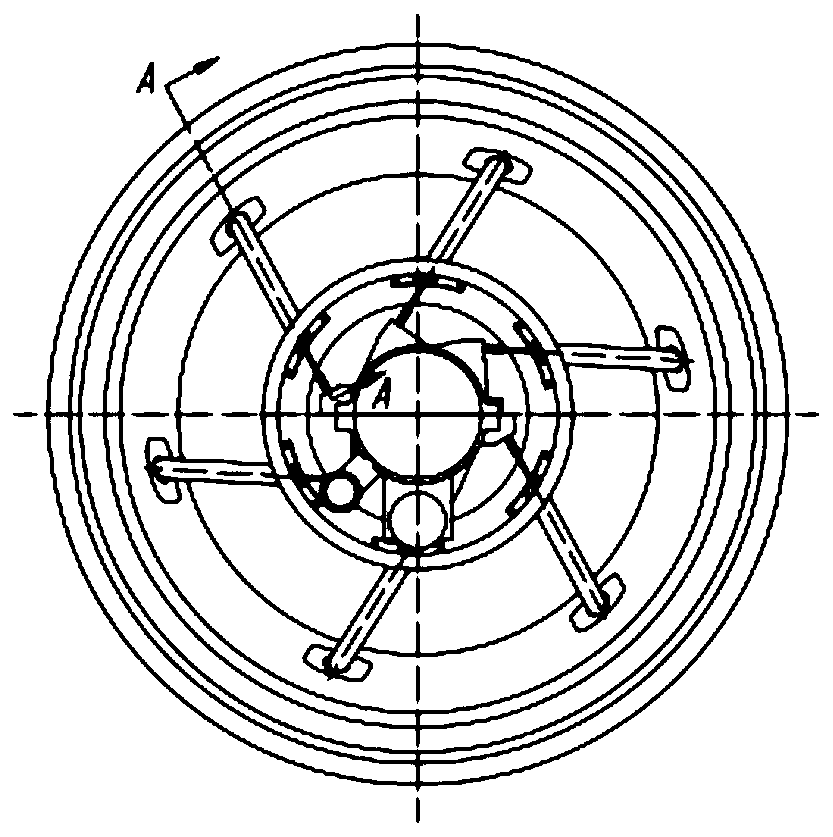

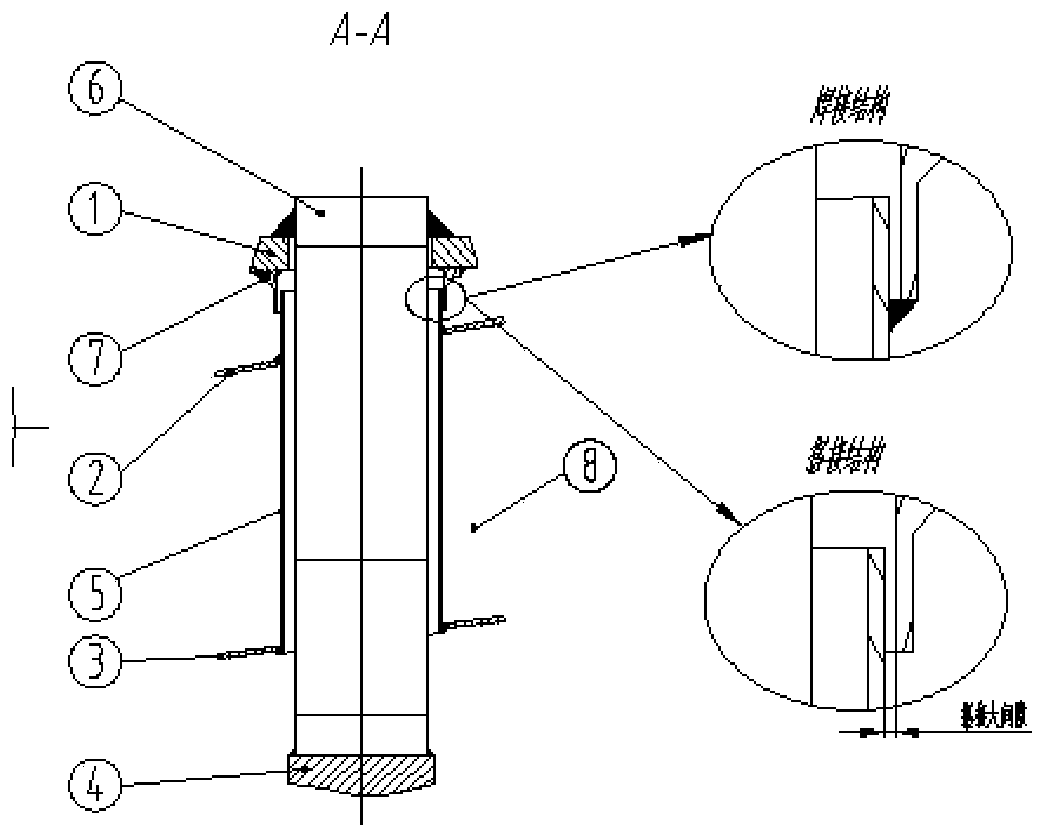

[0034] A small and medium-sized gas turbine exhaust cylinder internal flow channel support structure, including an outer cylinder body 1, a bearing seat 4 and an inner flow channel 8, and also includes a hollow oval tubular support tube 5, integrally formed by two sections of rectangular rods with different widths and the same length Symmetrical support rod 6, and elliptical hollow rounded platform guard plate 7;

[0035] The support rod 6 passes through the inner flow channel 8 and one end with a narrower width is connected to the bearing housing 4, and the other end is connected to the outer cylinder body 1;

[0036] The support tube 5 is sleeved on the outside of the support rod 6;

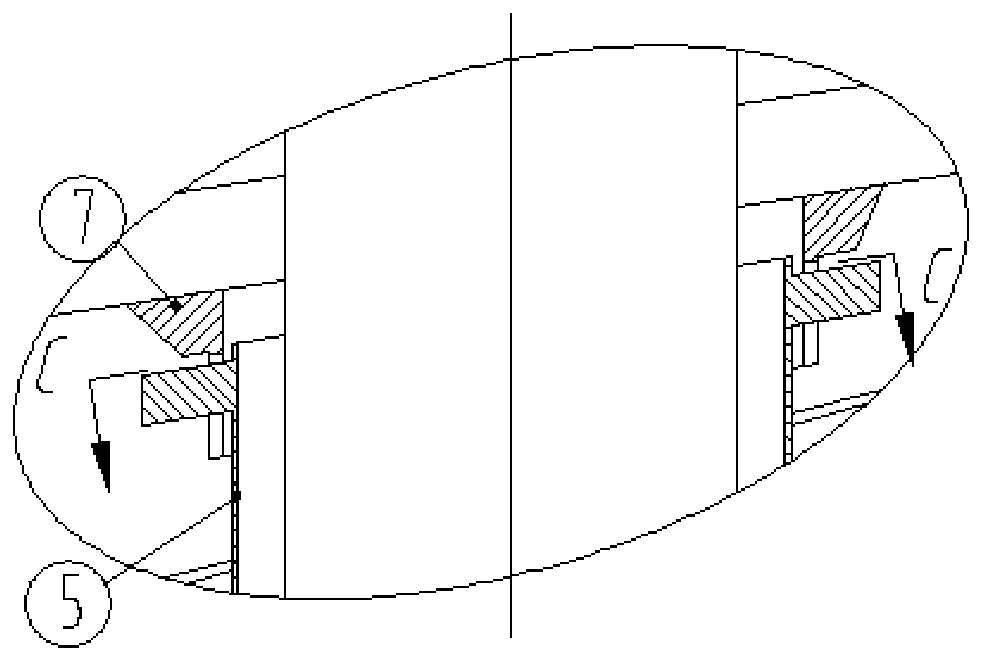

[0037] One end of the guard plate 7 with thicker wall thickness is fixed on the outer cylinder body 1 , and the other end is sleeved on the outside of the support tube 5 , and the support tube 5 can slide inside the guard plate 7 along its axis.

[0038] Two guide blocks 51 are provided on the...

Embodiment 2

[0046] A small and medium-sized gas turbine exhaust cylinder internal flow channel support structure, including an outer cylinder body 1, a bearing seat 4 and an inner flow channel 8, and also includes a hollow oval tubular support tube 5, integrally formed by two sections of rectangular rods with different widths and the same length Symmetrical support rod 6, and elliptical hollow rounded platform guard plate 7;

[0047] The support rod 6 passes through the inner flow channel 8 and one end with a narrower width is connected to the bearing housing 4, and the other end is connected to the outer cylinder body 1;

[0048] The support tube 5 is sleeved on the outside of the support rod 6;

[0049] One end of the guard plate 7 with thicker wall thickness is fixed on the outer cylinder body 1 , and the other end is sleeved on the outside of the support tube 5 , and the support tube 5 can slide inside the guard plate 7 along its axis.

[0050] Two guide blocks 51 are provided on the...

Embodiment 3

[0056] A small and medium-sized gas turbine exhaust cylinder internal flow channel support structure, a small and medium gas turbine exhaust cylinder internal flow channel support structure, including an outer cylinder body 1, a bearing seat 4 and an inner flow channel 8, and also includes a hollow oval tubular support cylinder 5, A symmetrical supporting rod 6 integrally formed by two sections of rectangular rods with different widths and the same length, and an elliptical hollow rounded platform guard plate 7;

[0057] The support rod 6 passes through the inner flow channel 8 and one end with a narrower width is connected to the bearing housing 4, and the other end is connected to the outer cylinder body 1;

[0058] The support tube 5 is sleeved on the outside of the support rod 6;

[0059] One end of the guard plate 7 with thicker wall thickness is fixed on the outer cylinder body 1 , and the other end is sleeved on the outside of the support tube 5 , and the support tube 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com