Single-diaphragm preforming method for composite lamination

A composite material lamination and composite material technology, which is applied in the field of single diaphragm preforming of composite material lamination, can solve the problems of cumbersome operation, high cost, unstable quality, etc., and achieves simple operation, good applicability, and good consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

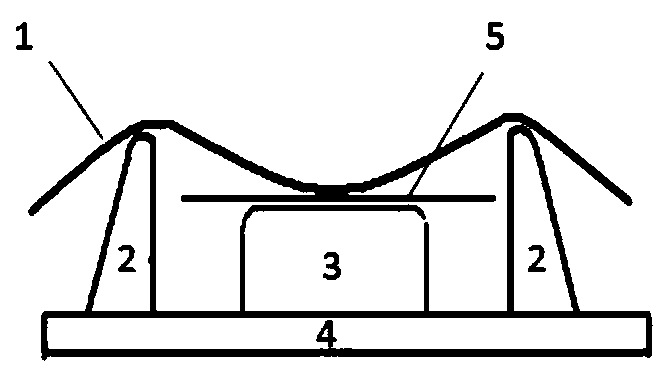

[0034] Embodiment one: if image 3 C-section composite laminate preform shown:

[0035] 1) layup

[0036] Use an automatic tape-laying machine to lay composite material slab laminates 5 according to the lay-up information of structural parts;

[0037] 2) Equipment preparation and tooling preparation

[0038] Place the forming tooling 3 on the vacuum working platform 4 of the preforming equipment, and then place the auxiliary supporting device 2 parallel to the forming tooling 3 on both sides of the forming tooling 3. The height of the forming tooling 3 is 300 mm, and the height of the auxiliary supporting device 2 is 350 mm. The distance between the two is 250mm. Cover auxiliary support unit 2 with airfelt or other soft material. Check whether there are sharp protrusions or depressions on the forming tooling 3 and the vacuum working platform 4, and protect them so as not to tear the silicone rubber film 1 during the preforming process.

[0039] 3) Preheating tooling 3

...

Embodiment 2

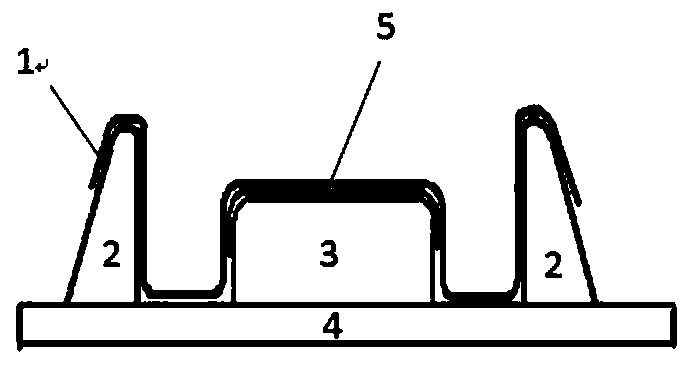

[0047] Embodiment two: if Figure 4 Concave cross-section composite laminate preform shown:

[0048] 1) layup

[0049] Use an automatic tape-laying machine to lay composite material slab laminates 5 according to the lay-up information of structural parts;

[0050] 2) Equipment preparation and tooling preparation

[0051] Place the forming tooling 3 on the vacuum working platform 4 of the preforming equipment, and then place the auxiliary supporting device 2 parallel to the forming tooling 3 on both sides of the forming tooling 3. The forming tooling 3 is 200 mm high, and the auxiliary supporting device 2 is 250 mm high. The distance between the two 200mm. Cover auxiliary support unit 2 with airfelt or other soft material. Check whether there are sharp protrusions or depressions on the forming tooling 3 and the vacuum working platform 4, and protect them so as not to tear the silicone rubber film 1 during the preforming process.

[0052] 3) Preheating tooling 3

[0053] Arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com