A kind of hexagonal sheet mesoporous nickel oxide and its preparation method and application

A technology of hexagonal flakes and nickel oxide, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of high energy consumption and cumbersome experimental process, and achieve the effects of improving lithium battery performance, promoting diffusion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put a 100mL beaker on a magnetic stirrer, add 35mL of distilled water and raise the temperature to 30°C, add 0.15g of CTAB to the distilled water under stirring, after the solution is stirred overnight and becomes transparent, add 0.17g of DDAB, and continue stirring until completely dissolved . Then add 0.70mL of ammonia water with a volume ratio of 25%. After stirring and reacting for 2.5h, slowly add 3.0g Ni(NO 3 ) 2 ·6H 2 O, after sealing, continue to stir and react at 30° C. for 24 h to obtain a light green solution. The obtained light green solution was transferred to a 100mL reactor, and placed in a 100°C thermostat for hydrothermal reaction for 12h. After cooling, the light green solution was centrifuged and washed. The washed precipitate was dried at 40° C. for 18 hours, and the dried precipitate was ground and then calcined at 500° C. for 2 hours to obtain nickel oxide powder.

Embodiment 2

[0037] Put a 100mL beaker on a magnetic stirrer, add 35mL of distilled water and raise the temperature to 30°C, add 0.15g of CTAB to the distilled water under stirring, after the solution is stirred overnight and becomes transparent, add 0.17g of DDAB, and continue stirring until completely dissolved . Then add 0.70mL of ammonia water with a volume ratio of 25%. After stirring and reacting for 2.5h, slowly add 3.0g Ni(NO 3 ) 2 ·6H 2 O, after sealing, continue to stir and react at 30° C. for 24 h to obtain a light green solution. The obtained light green solution was transferred to a 100mL reactor, and placed in a 100°C thermostat for hydrothermal reaction for 24h. After cooling, the light green solution was centrifuged and washed. The washed precipitate was dried at 40° C. for 18 hours, and the dried precipitate was ground and then calcined at 500° C. for 2 hours to obtain nickel oxide powder.

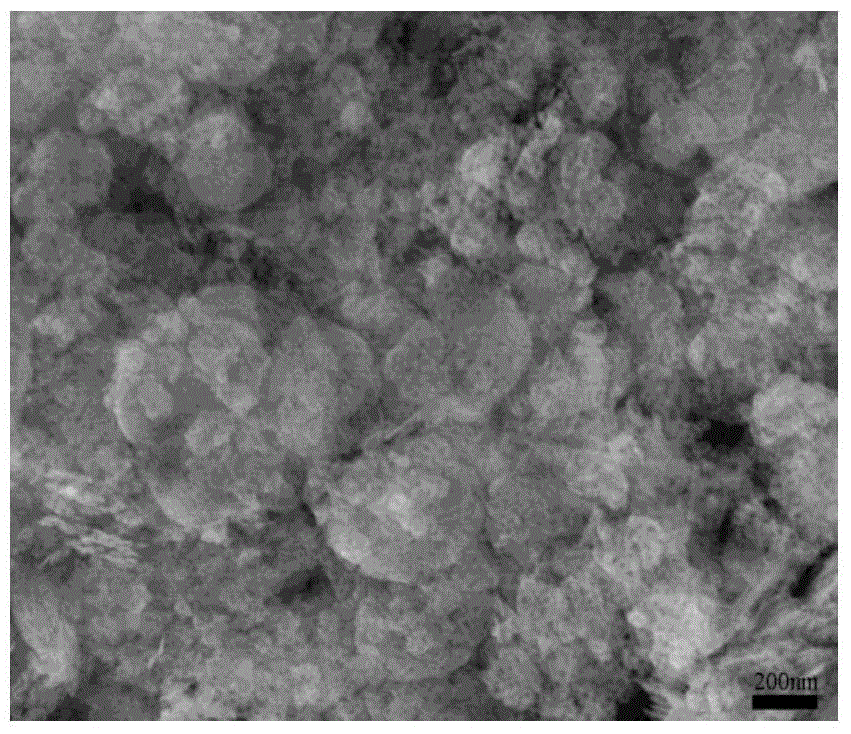

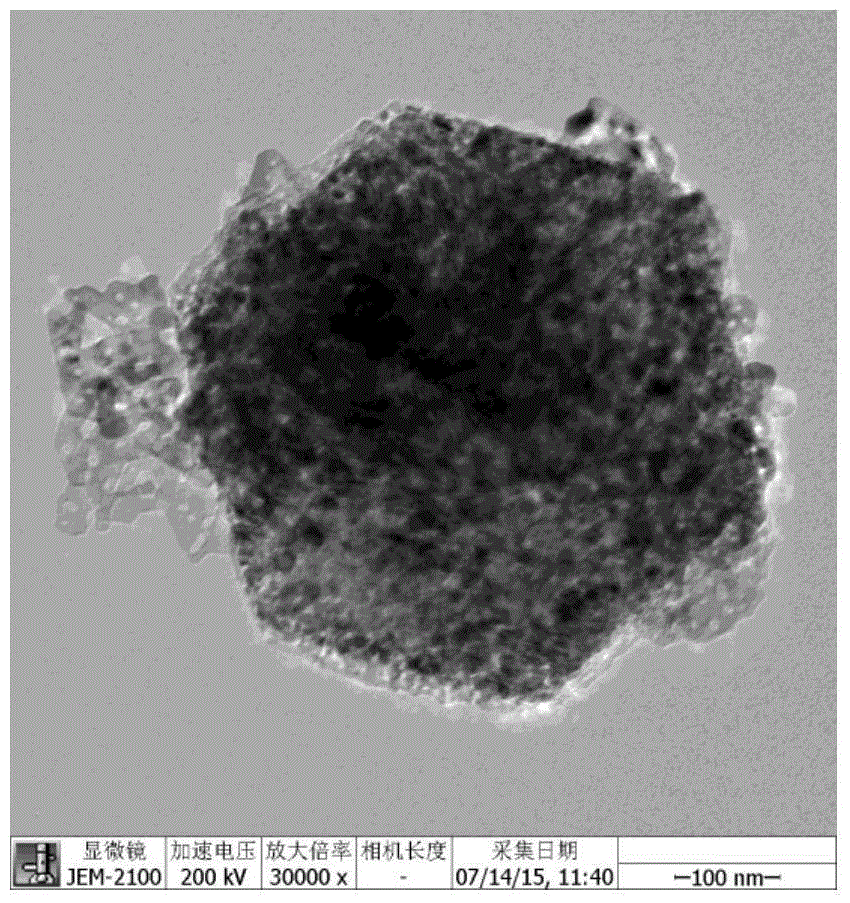

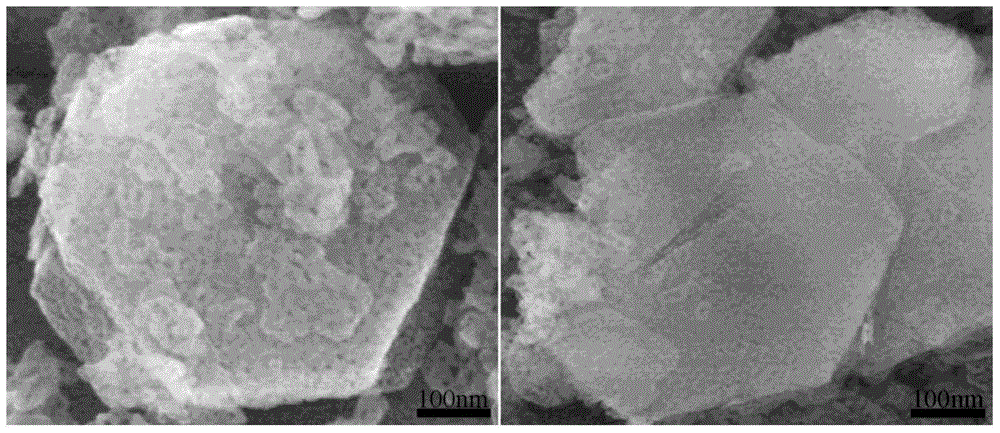

[0038] Observation with transmission electron microscope and scanning electro...

Embodiment 3

[0040] Put a 100mL beaker on a magnetic stirrer, add 32mL of distilled water and raise the temperature to 30°C, add 0.13g of CTAB to the distilled water under stirring, after the solution is stirred overnight and becomes transparent, add 0.14g of DDAB, continue to stir until completely dissolved . Then add 0.70mL of ammonia water with a volume ratio of 25%. After stirring and reacting for 2h, slowly add 3.0g Ni(NO 3 ) 2 ·6H 2 O, after sealing, continue to stir and react at 30° C. for 18 h to obtain a light green solution. The obtained light green solution was transferred to a 100 mL reactor, and placed in a thermostat at 110° C. for hydrothermal reaction for 48 h. After cooling, the light green solution was centrifuged and washed. The washed precipitate was dried at 40° C. for 12 hours, and the dried precipitate was ground and then calcined at 500° C. for 3 hours to obtain nickel oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com