Wind field environment pool fire burning rate test device for eliminating wind interference

A technology of combustion rate and testing device, which is applied in the direction of measuring device, machine/structural component testing, aerodynamic test, etc. It can solve the random disturbance of errors, single wind field environment creation, inaccurate mass data and fuel combustion rate and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

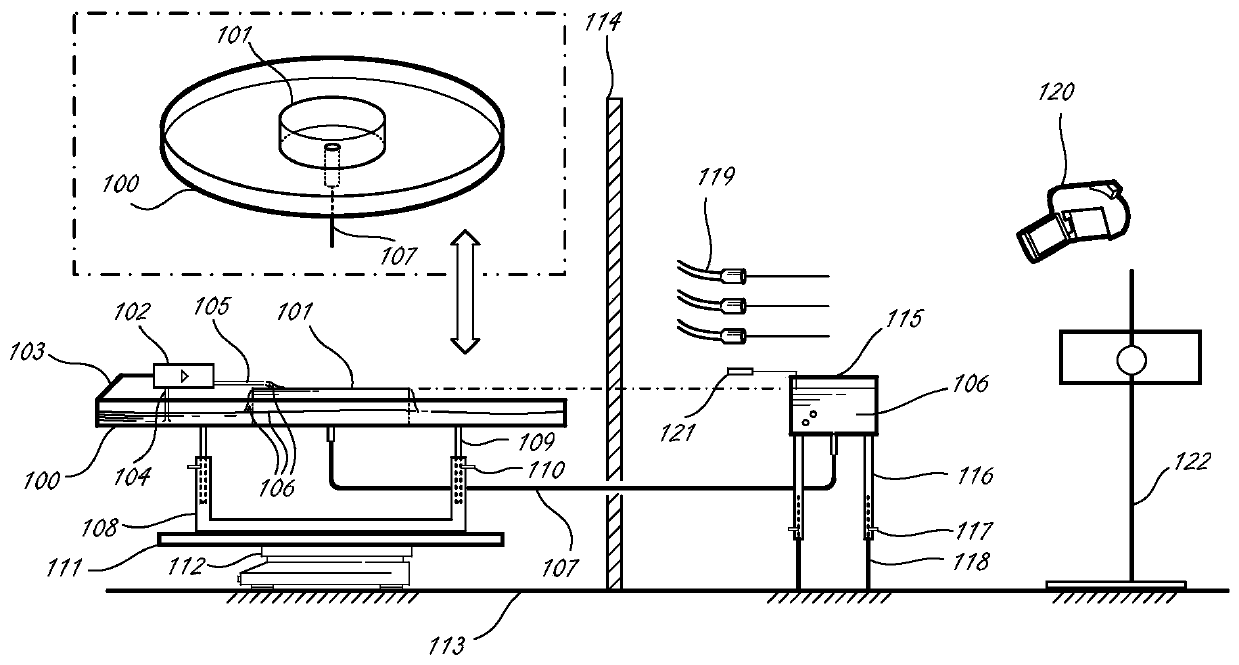

[0025] like figure 1 As shown, a disc-shaped liquid supply pool 100 made of stainless steel is welded at the center of a disc-shaped liquid stabilizing pool 101 made of stainless steel. A hole is drilled at the center of the bottom of the liquid stabilizing pool 101 and a section of stainless steel first conduit is welded. In this embodiment , the internal diameter of the liquid supply pool 100 is 80 cm, and the height of the inner wall is 10 cm, while the internal diameter of the stable liquid pool 101 is 20 cm, and the height of the inner wall is 12 cm, and the tops of both are open; in the liquid supply pool 100 A small liquid pump 102 powered by an internal lithium battery is welded to the edge of the plate wall through a liquid pump bracket 103. The liquid inlet pipe 104 of the small liquid pump 102 extends into the bottom of the liquid su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap