An electrochemical device and test method for simulating the rapid formation of pipe scale

An electrochemical and pipe scaling technology, applied in the fields of electrochemical variables of materials, measuring devices, preparation of samples for testing, etc., can solve the problems of a large number of pipe scale difficulties, long time for pipe scale formation, accelerated material transfer process, etc. It can quantify the effect of producing pipe scale, solving pipe scale for a long time, and accelerating the effect of material transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

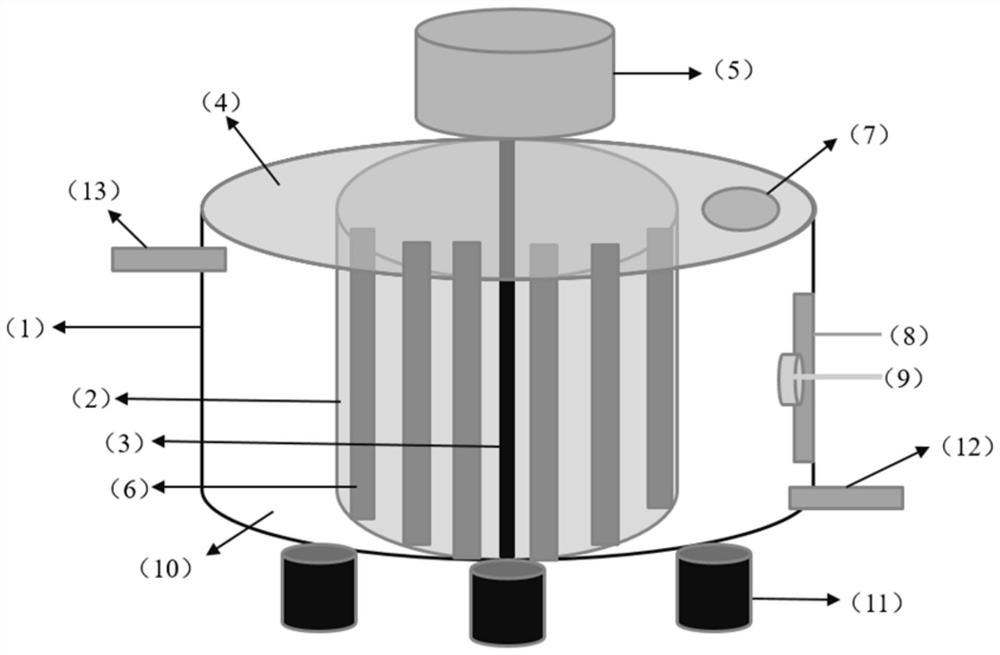

[0033]In a further step of the present invention, the material transfer process between the electrolyte and the metal hanger can be accelerated through the rotation of the vertical electrode, and the rapid formation of pipe scale is realized; at the same time, the metal hanger on the inner drum is directly used as the working electrode for electrolytic The chemical test realizes the high unification of rapid scale formation and electrochemical signal collection, solves the problem of long time for scale formation in actual pipelines, and provides a new device and method for rapid and quantifiable production of scale.

[0034] During the specific implementation process:

[0035] 1. Further, the outer cylinder of the main structure of the device is made of transparent plexiglass material, which is convenient for simultaneous observation of the growth of pipe scale. Among them, the diameter of the outer wall of the outer cylinder is 20cm, and the thickness is 3cm;

[0036] 2. Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com