Insulator fault detection and fault rating method based on image analysis

A fault detection and image analysis technology, which is applied in image analysis, image enhancement, image data processing, etc., can solve the problems of insulator porcelain body reducing dielectric strength, porcelain bottle broken circuit, low detection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

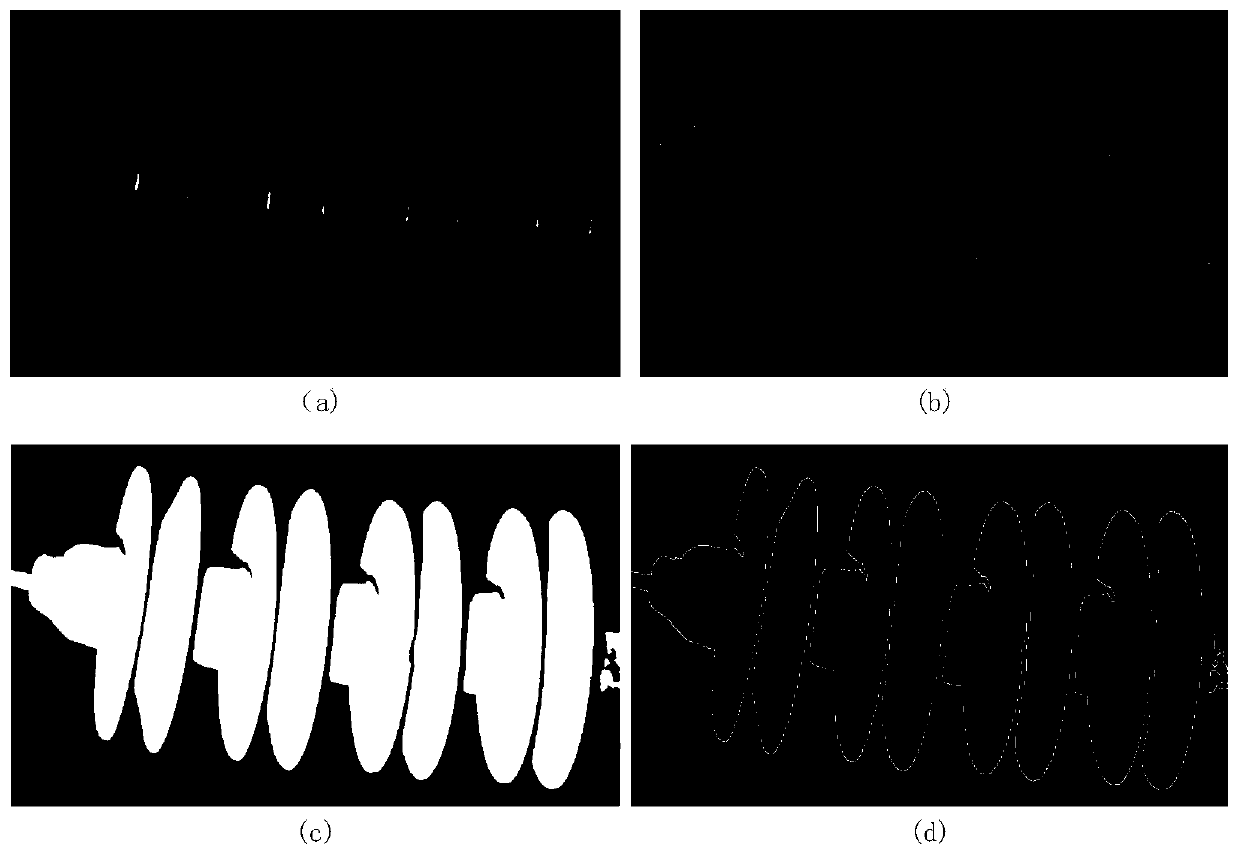

[0084] In order to make the technical solutions and implementation steps of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

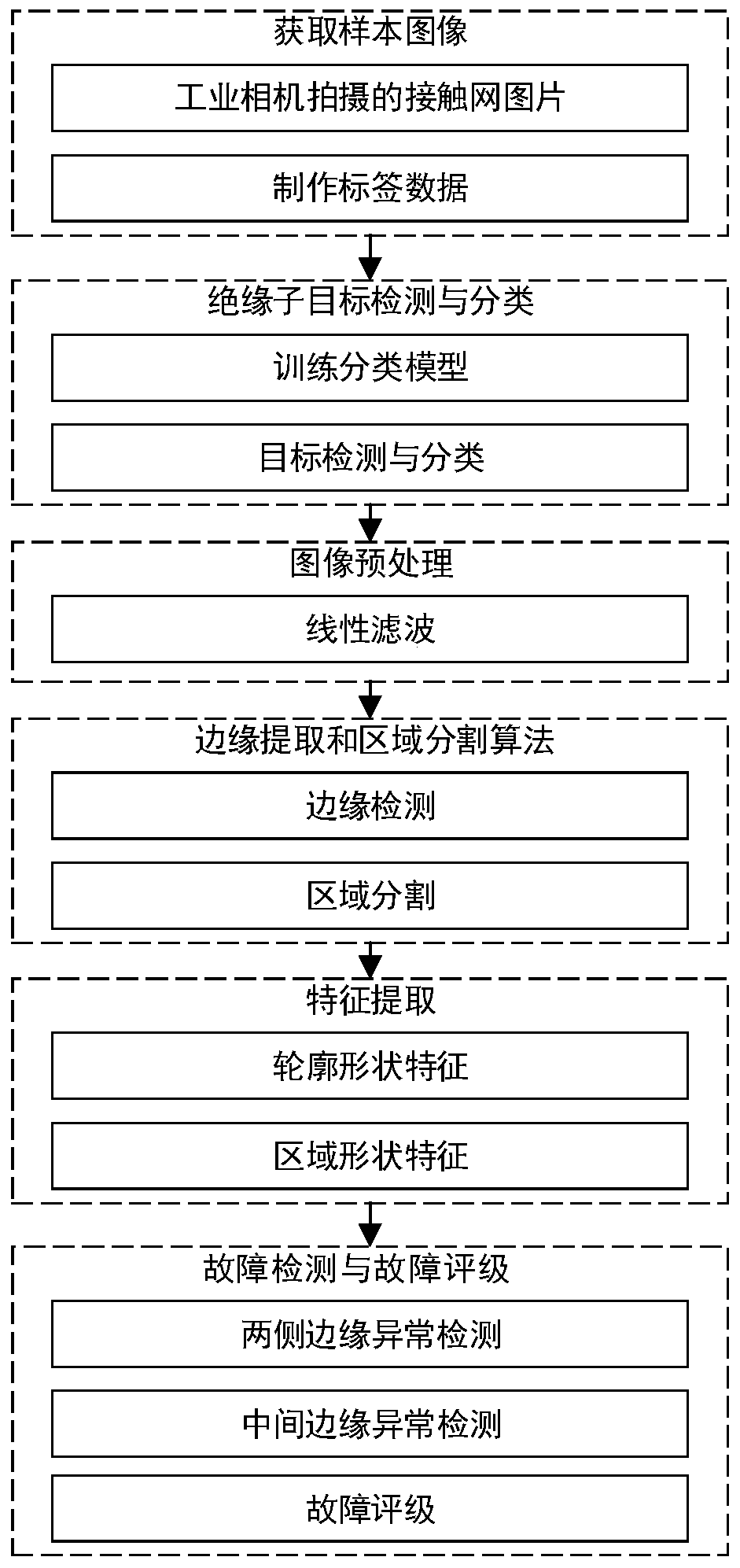

[0085] refer to figure 1 As shown, in this embodiment, the steps of the object detection method for key components of the catenary are as follows:

[0086] 1. Obtain sample images

[0087] Obtain the images of the catenary support device collected by the high-definition camera during the running of the train, screen out the insulators in the images as research samples, and make these images into data with labels. The size of the collected sample image is 4000*6000.

[0088] 2. Insulator target detection and classification

[0089] To detect the fault of insulators, we must first realize the target detection of insulators. At present, the best application method is the target detection network based on deep learning. The label data in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com