Organic light-emitting diode (OLED) device including mixed covering layer

A technology of electroluminescent devices and covering layers, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of reducing the light extraction efficiency of organic electroluminescent devices, so as to improve the light extraction efficiency and reduce the overall surface area of the interface. Chance of reflection, effects that increase extraction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1: manufacture OLED device of the present invention

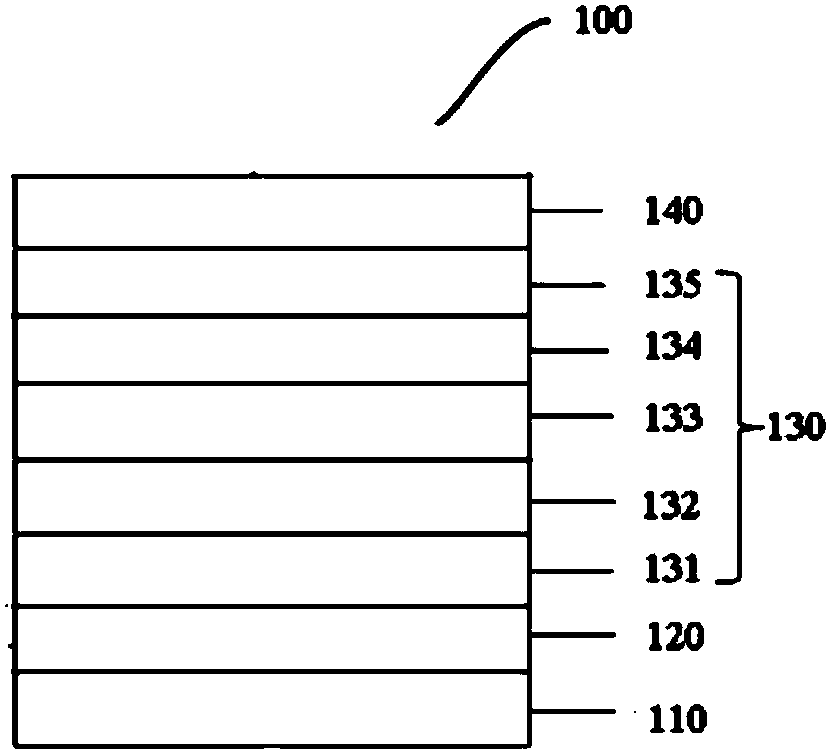

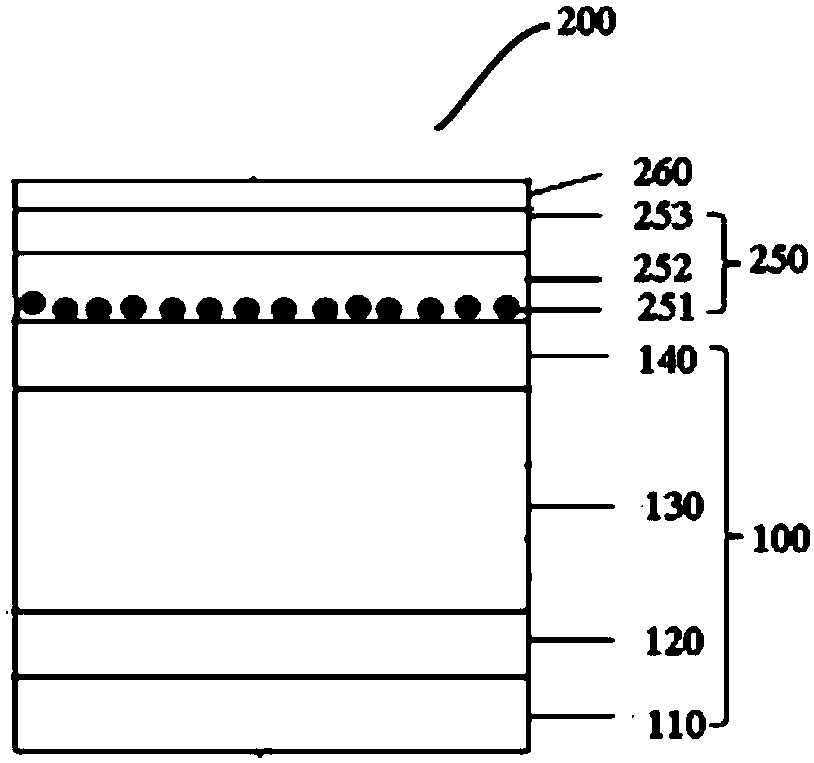

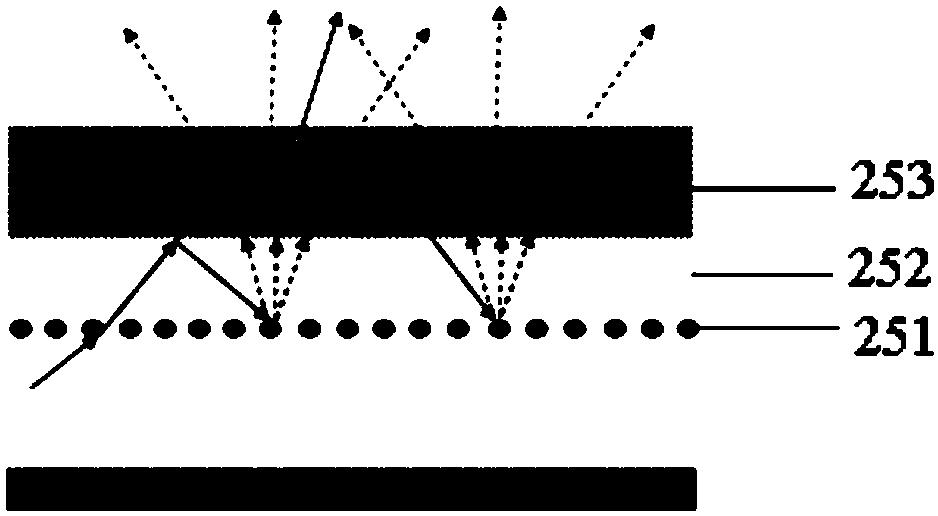

[0085] On the glass substrate (base layer 110), form the ITO opaque layer (reflective electrode layer 120) of 200nm by sputtering mode, and etch into the figure of demand, clean each 15 minutes respectively with deionized water, acetone, ethanol ultrasonically, then Treat in a plasma cleaner for 2 minutes; here the ITO electrode layer is the anode, and on the ITO anode layer, the hole injection layer material HAT-CN is evaporated by vacuum evaporation with a thickness of 10nm. This layer is used as a hole injection layer. Layer 131; on the hole injection layer 131, the hole transport layer material NPB is evaporated by vacuum evaporation, the thickness is 60nm, and this layer is the hole transport layer 132; on the hole transport layer 132, the green light emitting layer is evaporated Layer 133, CBP as host material, Ir(ppy) 3 As doping material, Ir(ppy) 3 The weight ratio to CBP is 1:9 (90wt% CBP), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap