IGBT drive peak detection and protection circuit

A technology of driving protection circuit and peak detection, applied in the field of electronics, can solve problems such as insufficient function, failure of protection circuit to detect faults, increase of output current of parallel IGBTs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

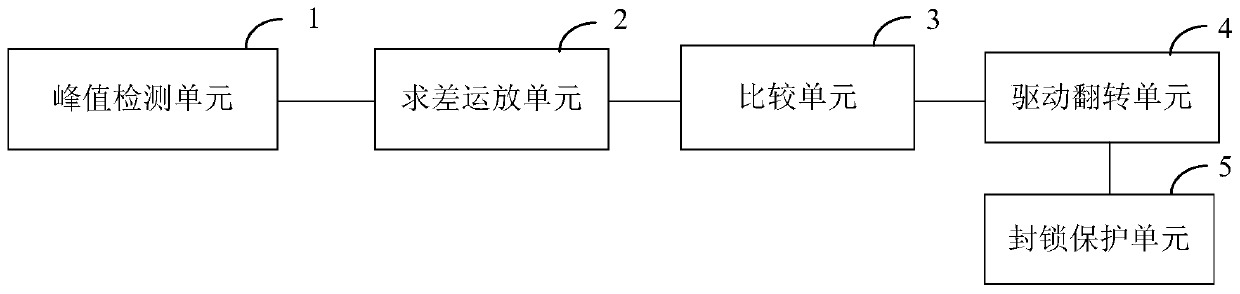

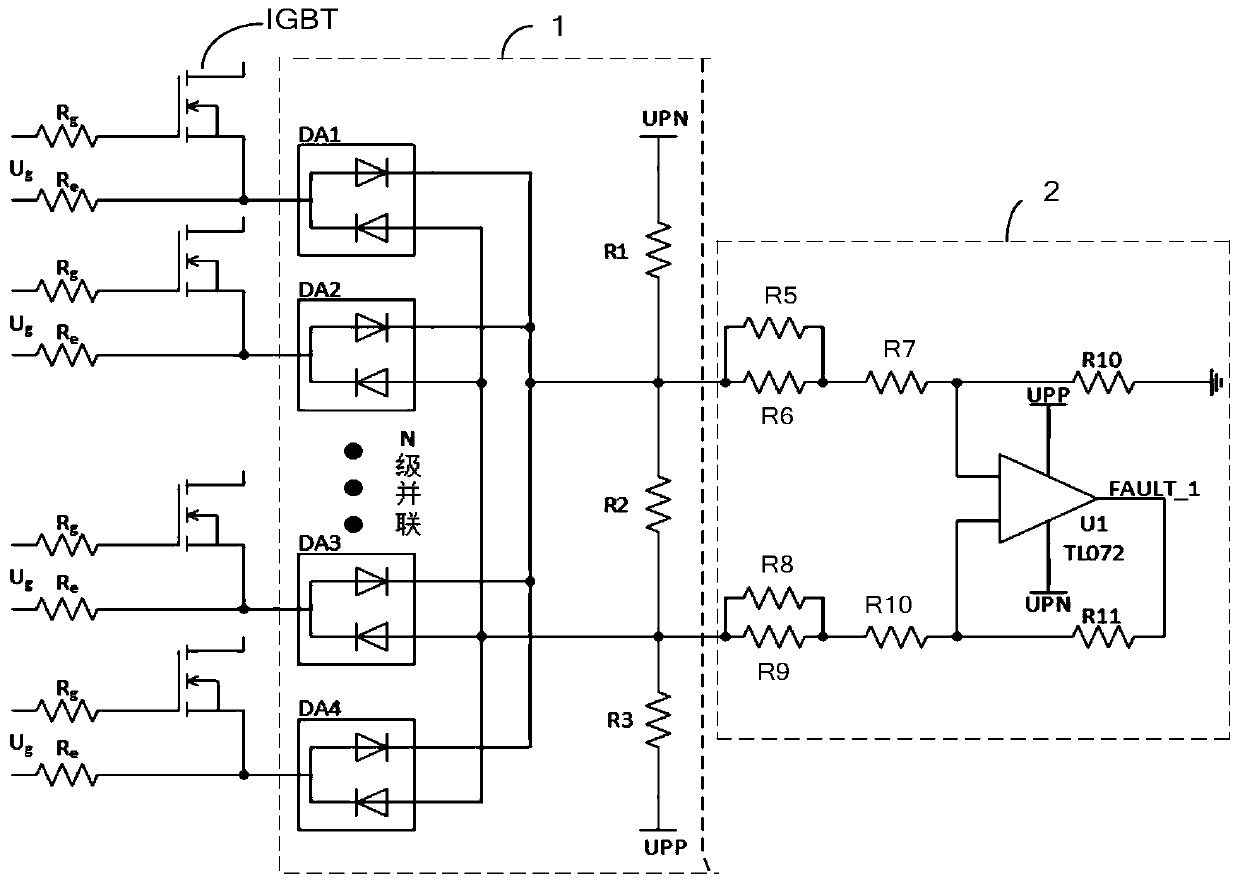

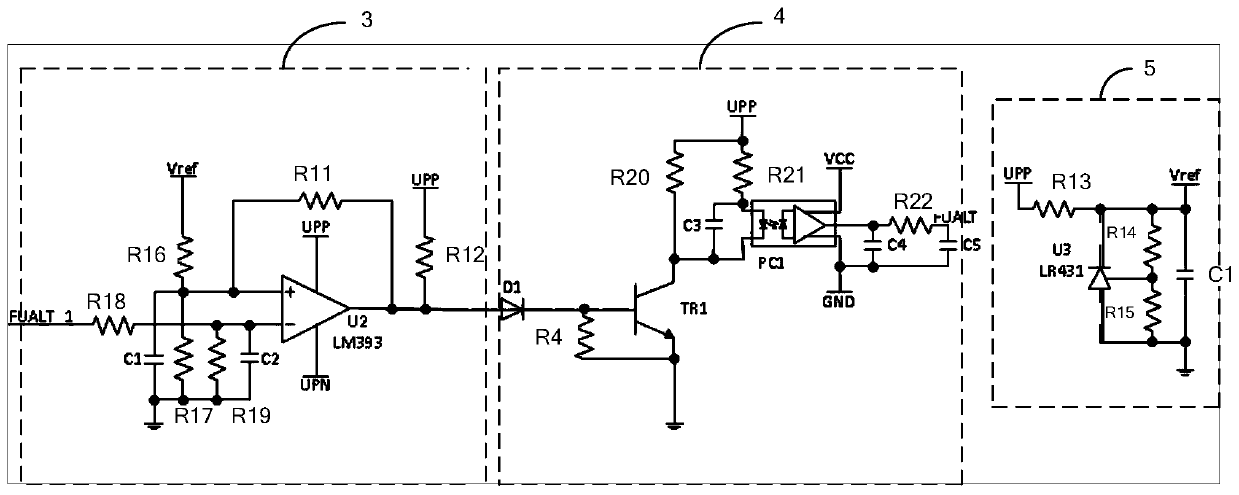

[0035] Such as figure 1 Shown is a structural block diagram of the IGBT driving peak detection and protection circuit proposed by the present invention. The IGBT driving peak detection and protection circuit is used to drive and protect multiple parallel IGBTs, which includes a peak detection unit 1 and a differential operational amplifier unit. 2, comparison unit 3, isolation unit 4 and blockade protection unit 5, wherein, the input end and output end of peak detection unit 1 are respectively connected with the emitter of IGBT and the input end of difference seeking amplification unit 2, the input end of comparison unit 3 The sum and output ends are respectively connected to the output end of the differential amplifier unit 2 and the input end of the isolation unit 4, and the output end of the isolation unit is connected to the blocking protection unit.

[0036] Wherein, the input terminal of the peak detection unit 1 is connected to the emitters of a plurality of IGBTs, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com