Shaver head structure and shaver

A razor and hole-one technology, applied in the field of razor head structure and razor, can solve the problems of increasing the difficulty of manufacturing and installation, complex structure of parts, poor structural strength, etc., to reduce the design complexity, Guaranteed shaving experience and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

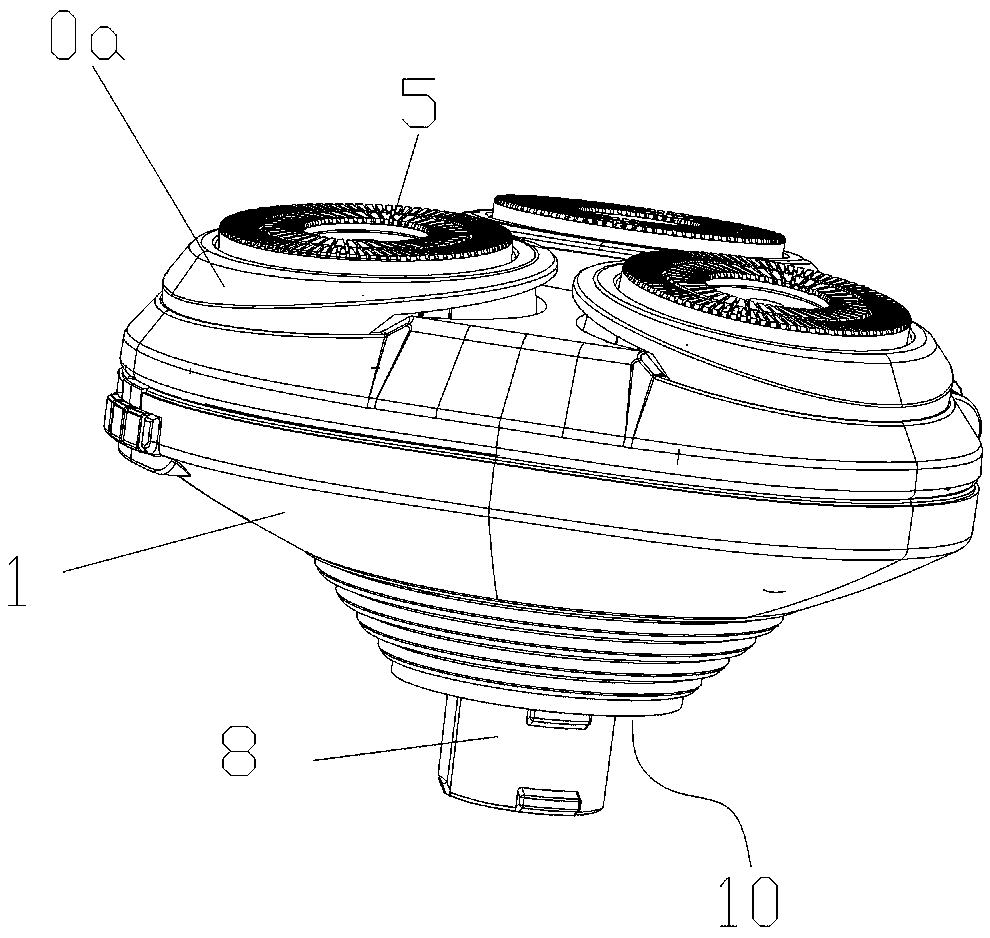

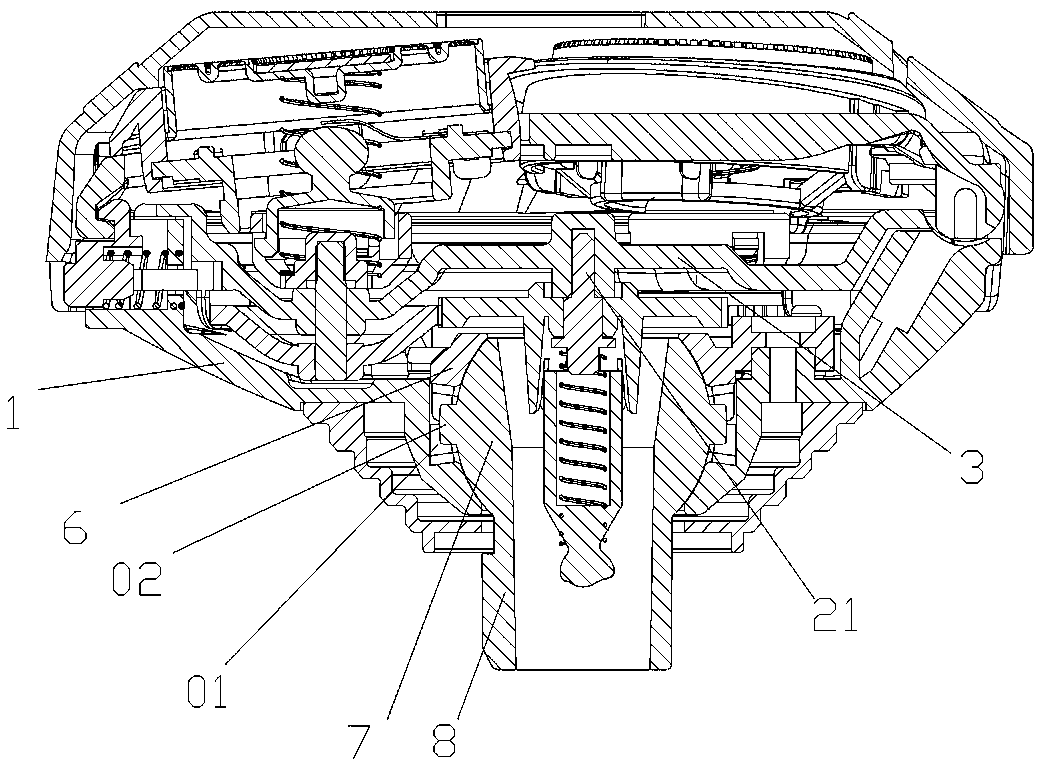

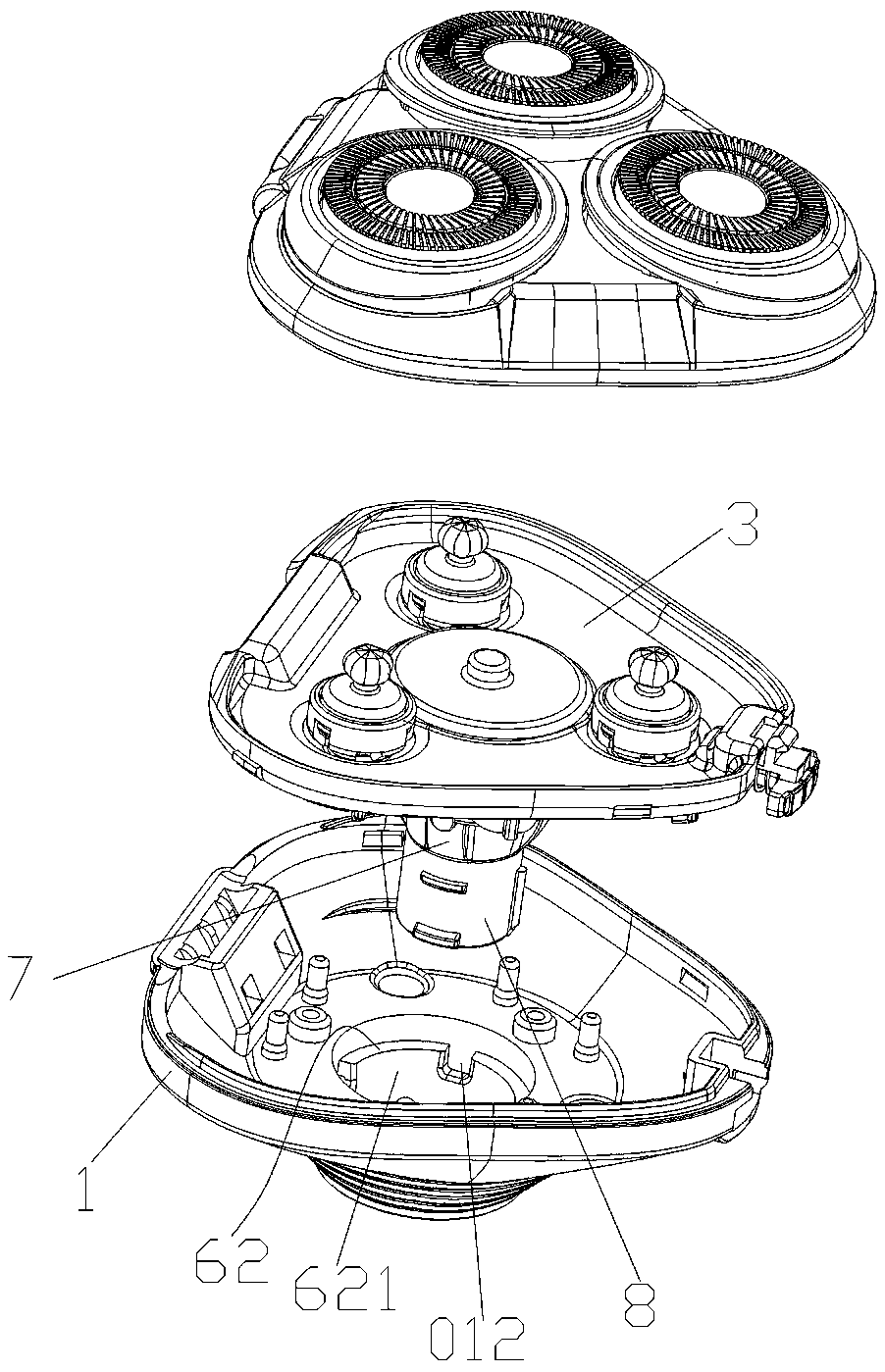

[0026] Embodiment 1: as Figure 1-7 As shown, a shaver head structure includes a housing 1, a driving gear 22 arranged in the housing 1 and a driven gear 42 meshing with the driving gear 22, and the housing 1 is also provided with There is a fixed plate 3, the outer edge of the fixed plate 3 matches the inner wall of the housing 1, and can be fixed with the housing 1 by clamping, and the driving gear 22 and the driven gear 42 pass through the driving gear shaft 21 respectively. and the driven gear shaft 41 are installed on the same side of the fixed plate 3, the driven gear shaft 41 is connected with the shaving assembly 5, the upper part of the housing 1 is connected with the upper cover body 0a, the shaving assembly 5 It is arranged on the upper cover body 0a, and the number of shaving assemblies 5 is at least three, and the space between the driving gear 22 and the bottom of the housing 1 is provided with a ball hinge seat 6 and the ball The hinged ball head 7 connected to...

Embodiment 2

[0034] Embodiment 2: a shaver, including a shaver head, and the shaver head is the shaver head with the structure in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com