Pallet separating mechanism and pallet separating method

A technology of dividing trays and trays, applied in the field of automation equipment, to achieve the effect of ingenious design, high work efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

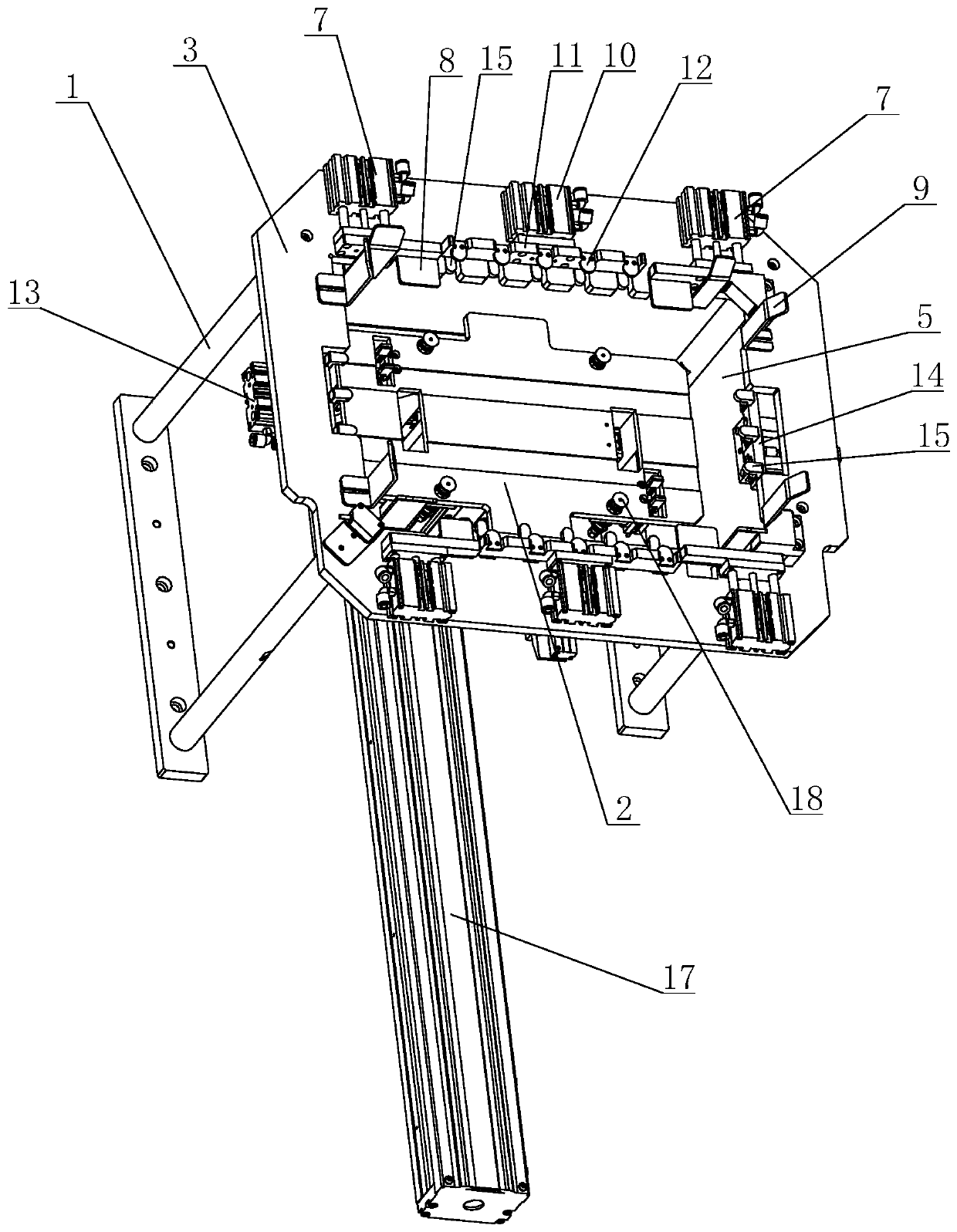

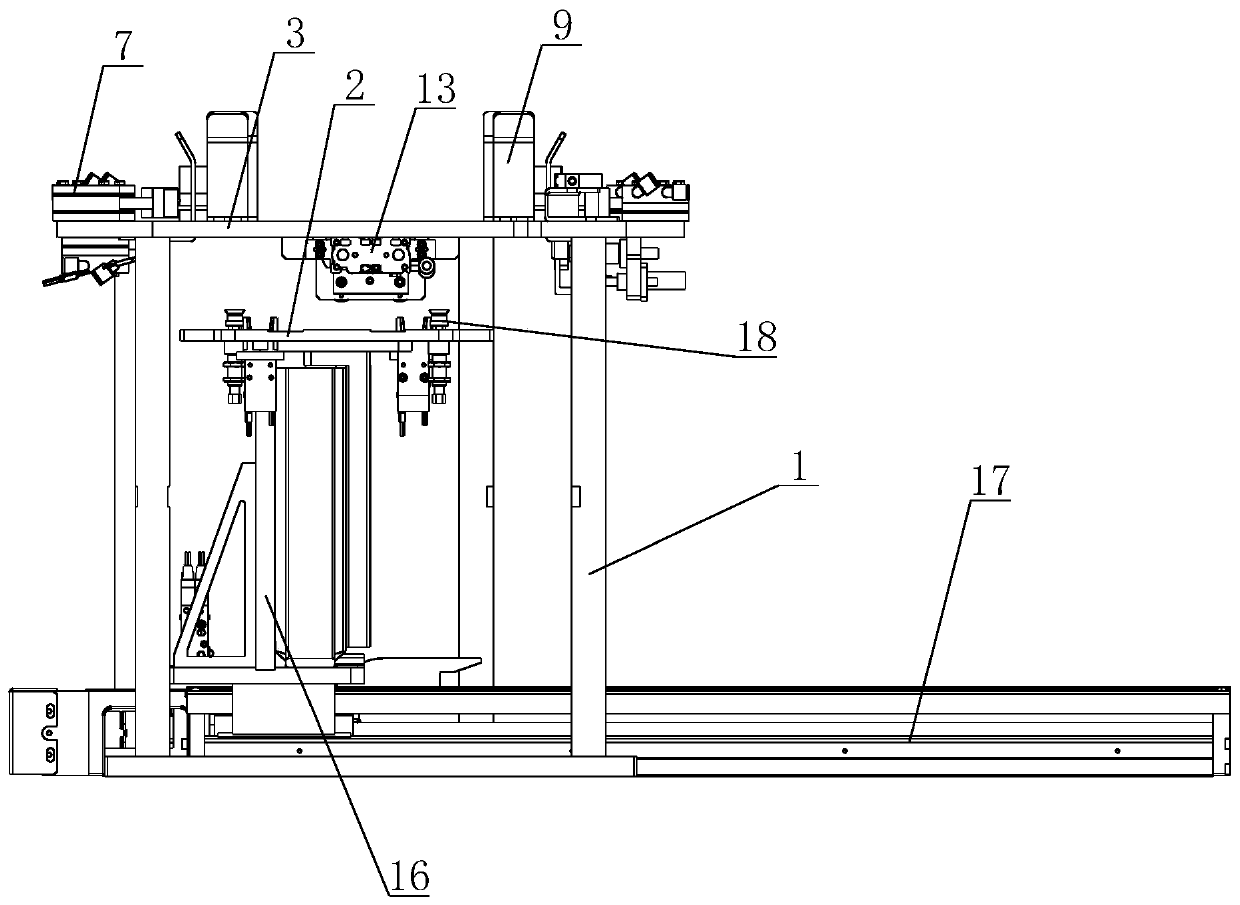

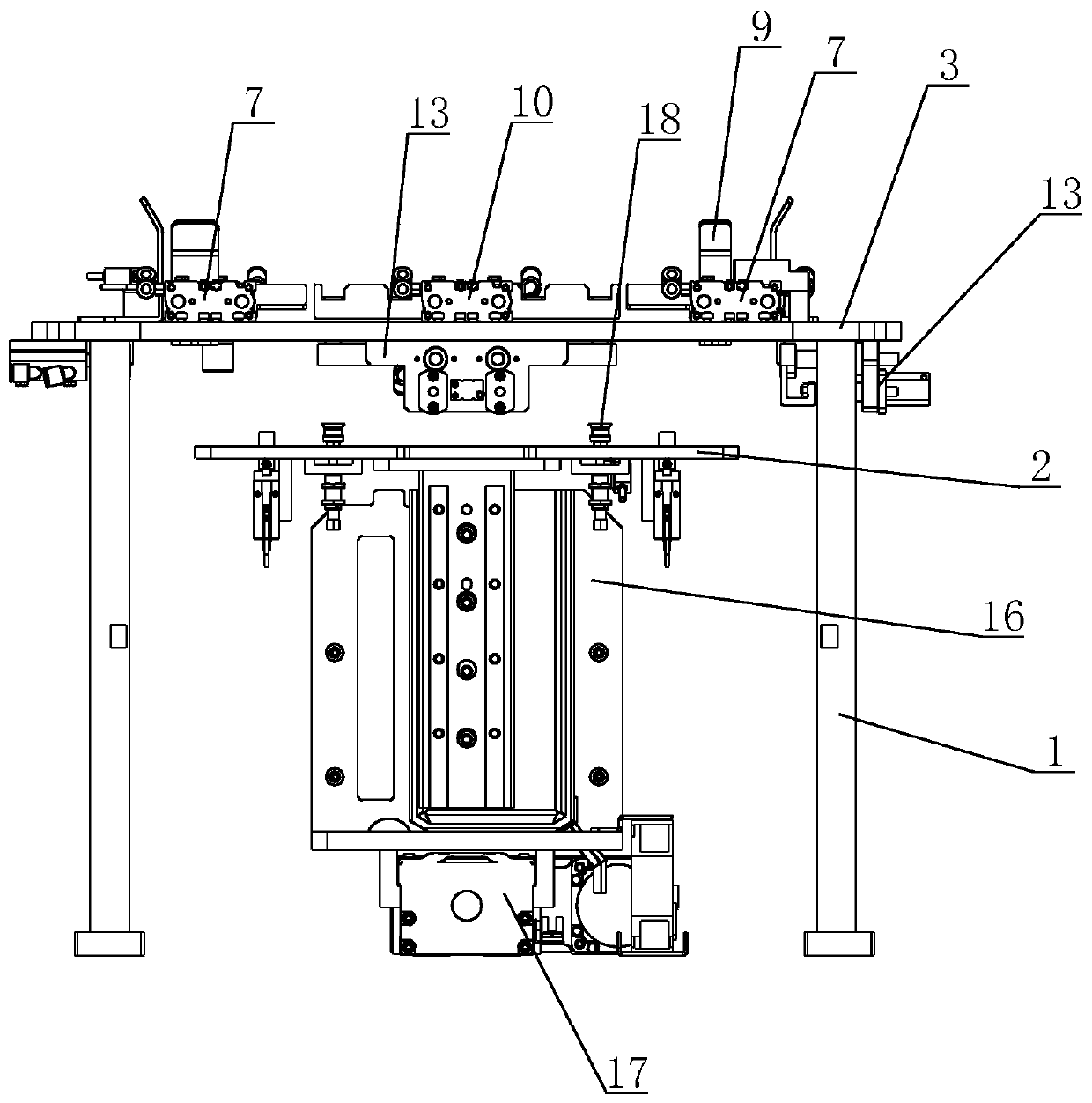

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0034] see Figure 1 to Figure 4 As shown, in this embodiment, a tray splitting mechanism includes a fixed frame 1 and a tray 2, the top of the fixed frame 1 is provided with a top plate 3, and the middle area of the top plate 3 is provided with a tray 4 for stacking Through the rectangular sub-disc passage 5, the tray 4 has a square structure as a whole, and the four side walls of the tray 4 are spaced apart along its height direction with several arc-shaped grooves 6 in cross-section, and the top of the groove 6 is open. The end is flush with the end face of the tray 4, and the bottom is closed. A pre-support cylinder 7 is installed on the end face of the top plate 3 outside the sub-disc passage 5. The end of the piston rod of the pre-support cylinder 7 is provided with a sub-disk through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com