Strip tensioning and winding assembly

A winding group and tensioning technology, which is applied in the field of amorphous thin strip tensioning components, can solve the problem that the winding roller cannot quickly absorb and break the strip, and achieve the effects of saving loading and unloading tools, reducing damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

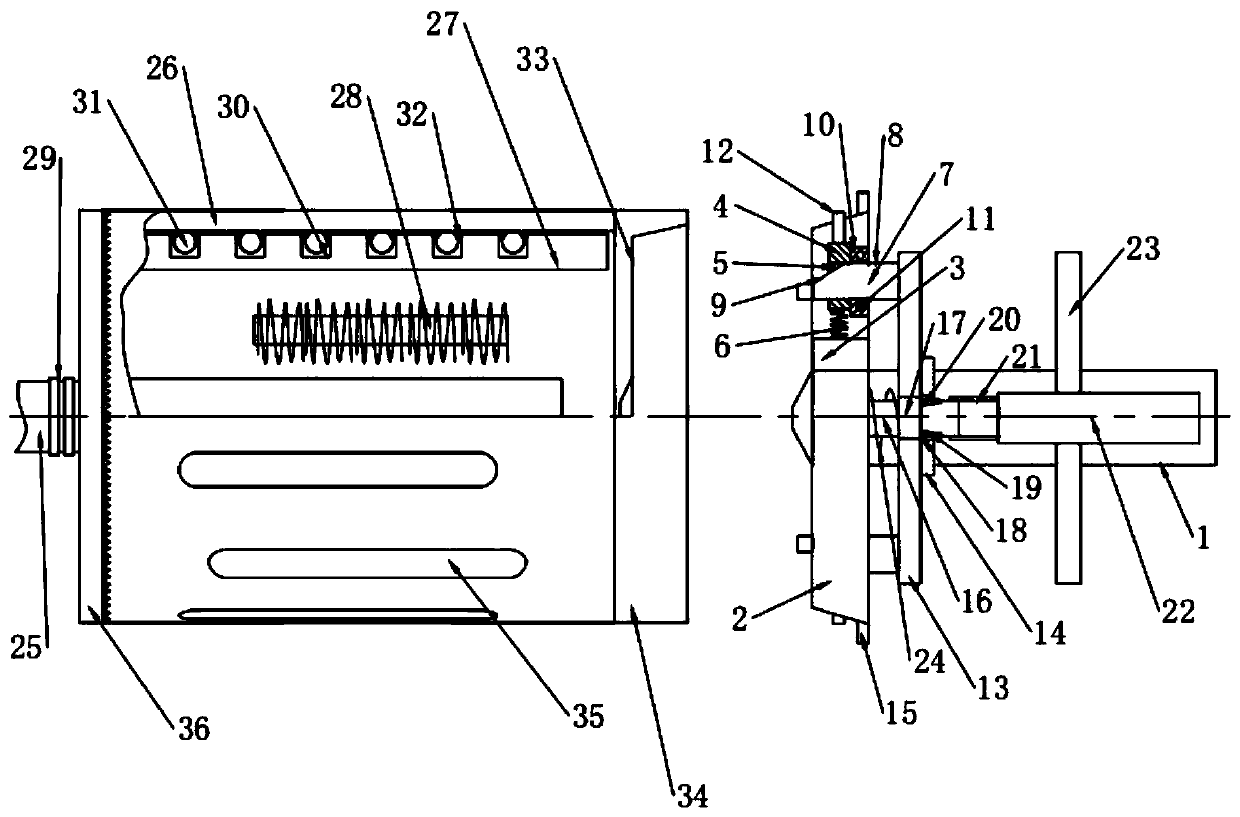

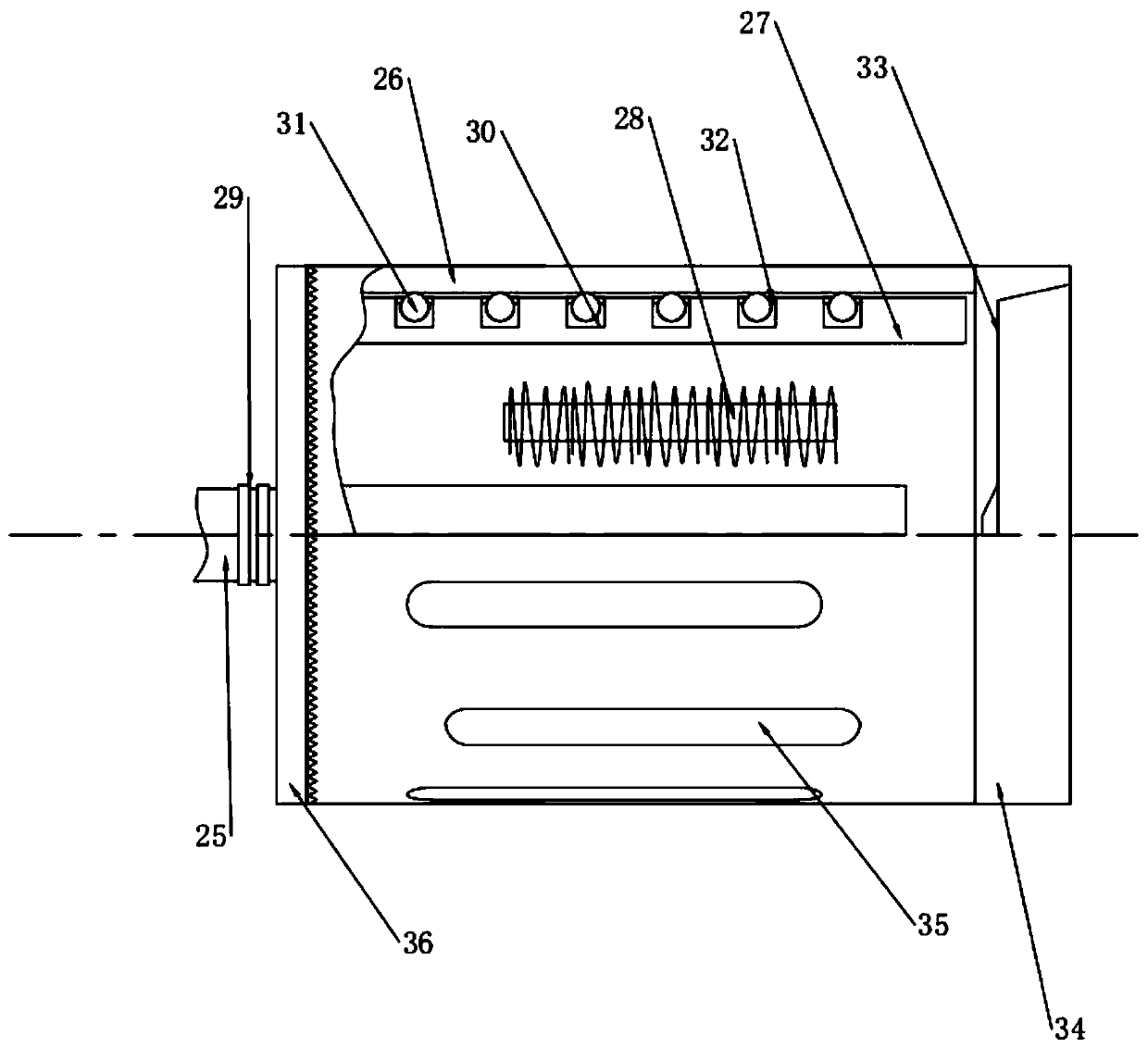

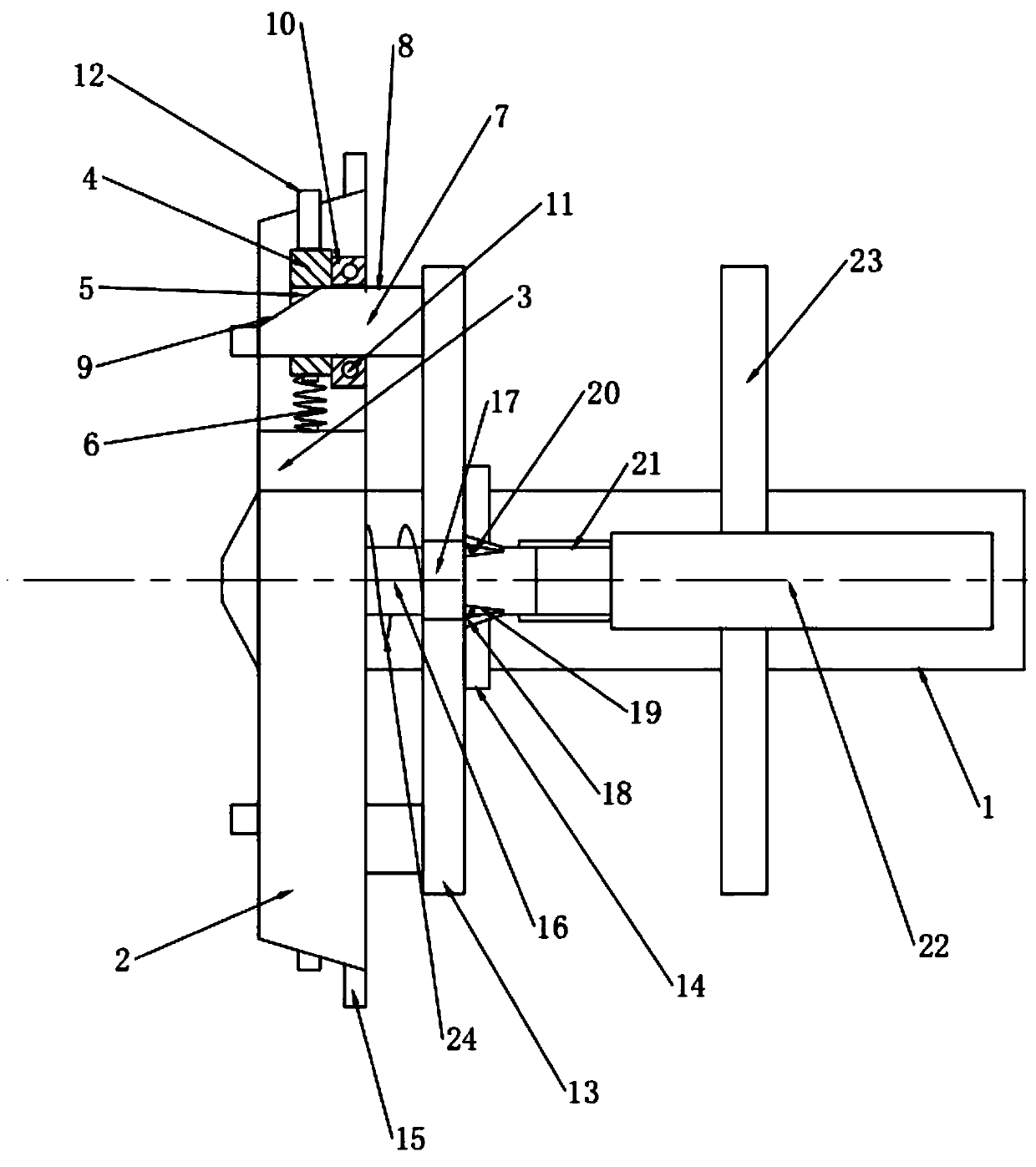

[0040] Such as Figure 1 to Figure 3 As shown, the strip tension winding assembly includes a driving roller 27, a winding roller 26, and a clamping disc 2 installed on the top 1; the clamping disc 2 performs an automatic clamping action after touching the winding roller 26, And drive the winding roller 26 to be clamped on the driving roller 27, and the driving roller 27 is equipped with a slip ring 29 and an inductance coil 28, the slip ring 29 is installed on one end of the driving roller 27, and the inductance coil 28 is surrounded by the driving roller 27. On the inner wall, the slip ring 29 is electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com