Wellhead ball catcher and ball catch method for staged fracturing of shale gas

A technology for staged fracturing and shale gas, which is applied in earth-moving drilling, wellbore/well components, and production fluids. , to achieve a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

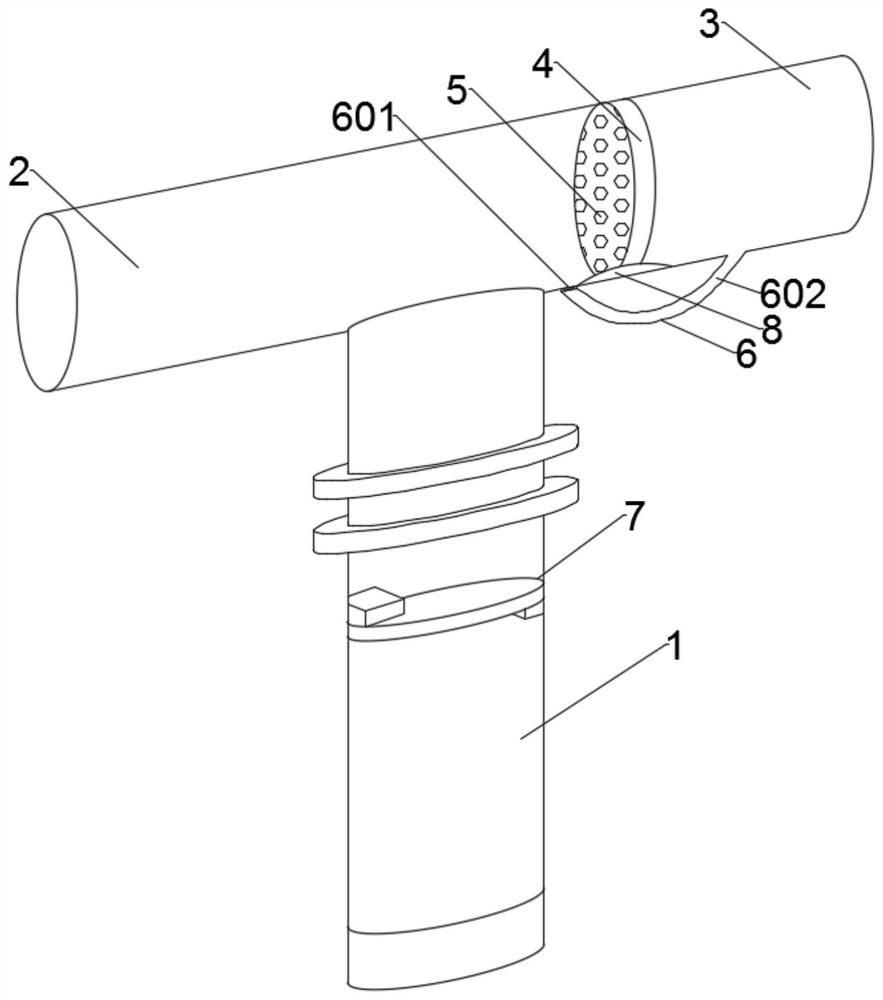

[0036] Such as figure 1 and figure 2 As shown, the invention provides a kind of wellhead ball catcher for staged fracturing of shale gas. The fracturing ball and the fracturing fluid are sucked out synchronously. When the wellhead ball catcher takes out the fracturing ball in the horizontal well, it separates the splitting fluid and the splitting ball. The ball falls back into the well, which is easy to catch the metal ball.

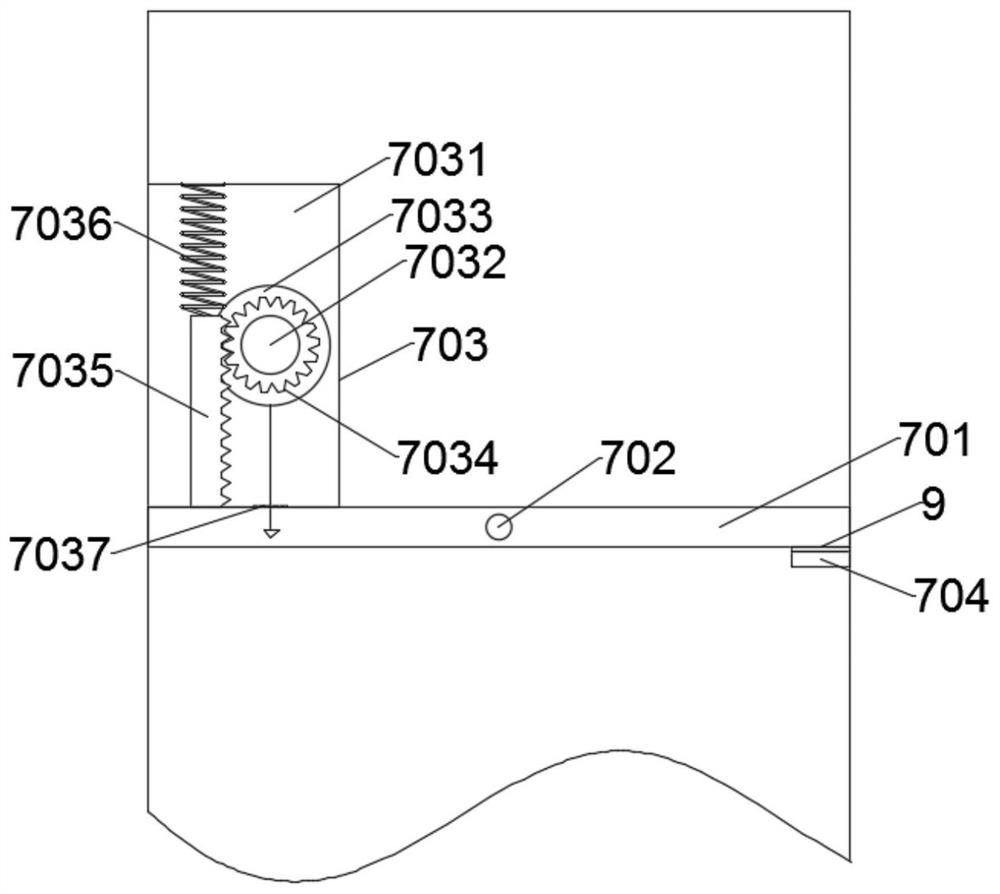

[0037] Second, in order to ensure the tightness of the wellhead ball catcher, reduce the working intensity of the power pump group, and discharge and collect the splitting balls from the wellhead ball catcher in time, this embodiment adds blades that can be turned over automatically on the wellhead ball catcher. It can be turned over to discharge the fracturing ball, and at the same time, it can also automatically reset and seal, without manual discharge of the fracturing ball, which is easy to operate and simple to implement.

[0038] It specificall...

Embodiment 2

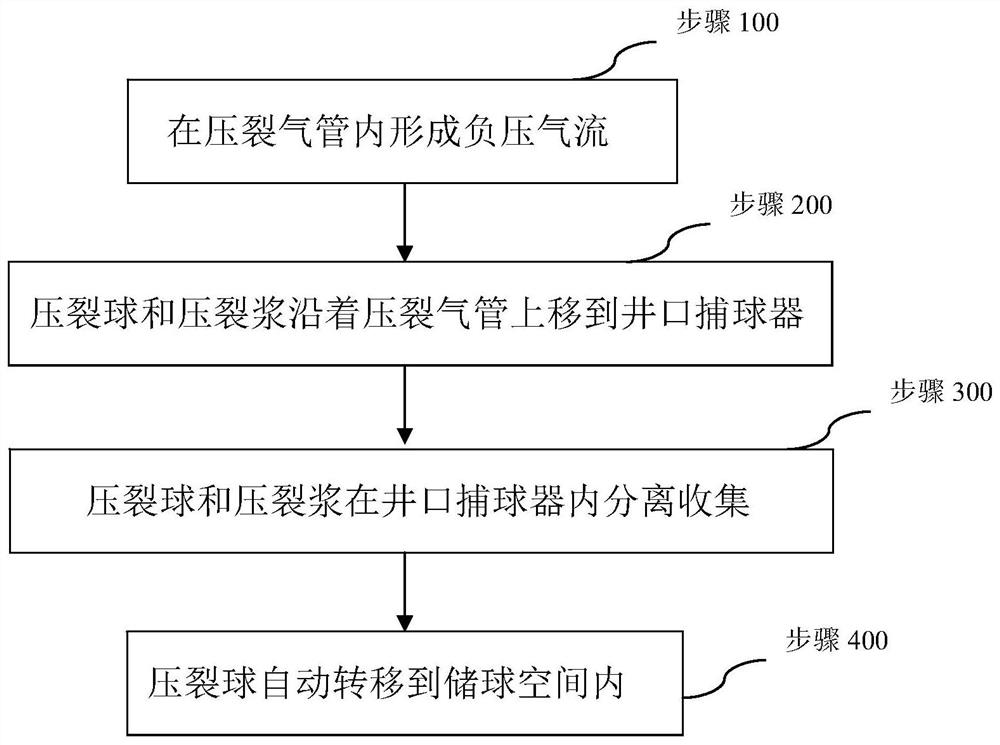

[0056] Such as image 3 As shown, in order to further illustrate the working mode of the same type of ball catcher, the present invention additionally provides a method for catching balls at the wellhead for staged fracturing of shale gas, comprising the following steps:

[0057] Step 100, open the manual pressurization valve of the wellhead ball catcher, and the power pump connected to the wellhead ball catcher works to form a negative pressure airflow in the fracturing gas pipe;

[0058] Step 200, gradually increasing the working intensity of the power pump until the fracturing balls and fracturing slurry move up the fracturing air pipe to the wellhead ball catcher;

[0059] Step 300, the fracturing balls and the fracturing slurry are separated and collected in the wellhead ball catcher;

[0060] Step 400, dividing the ball storage space and the ball catch space of the wellhead ball catcher, and the fracturing balls are automatically transferred into the ball storage space....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com