Method for mining remaining oil in bottom water heavy oil reservoir through non-condensate gas injecting or in-situ combustion

A technology for heavy oil reservoirs and remaining oil, applied in the field of remaining oil, can solve the problems of reducing the thermal efficiency of steam injection production, shutting down production wells, affecting the development efficiency of oil reservoirs, etc., and achieving the effect of improving the ultimate recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

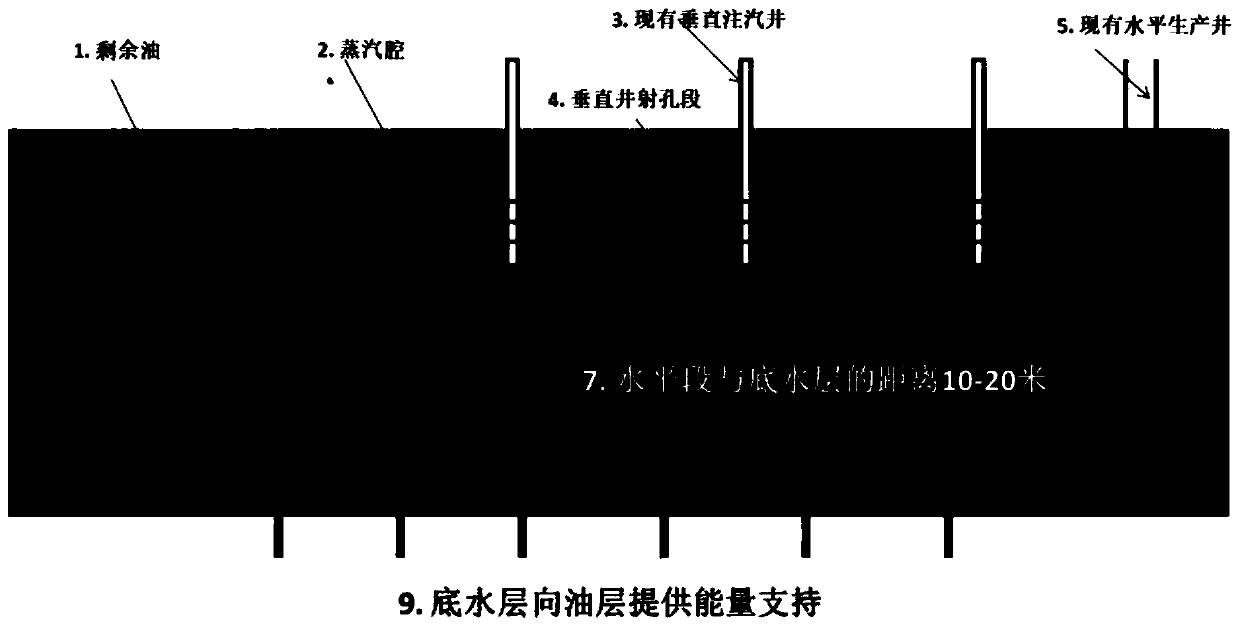

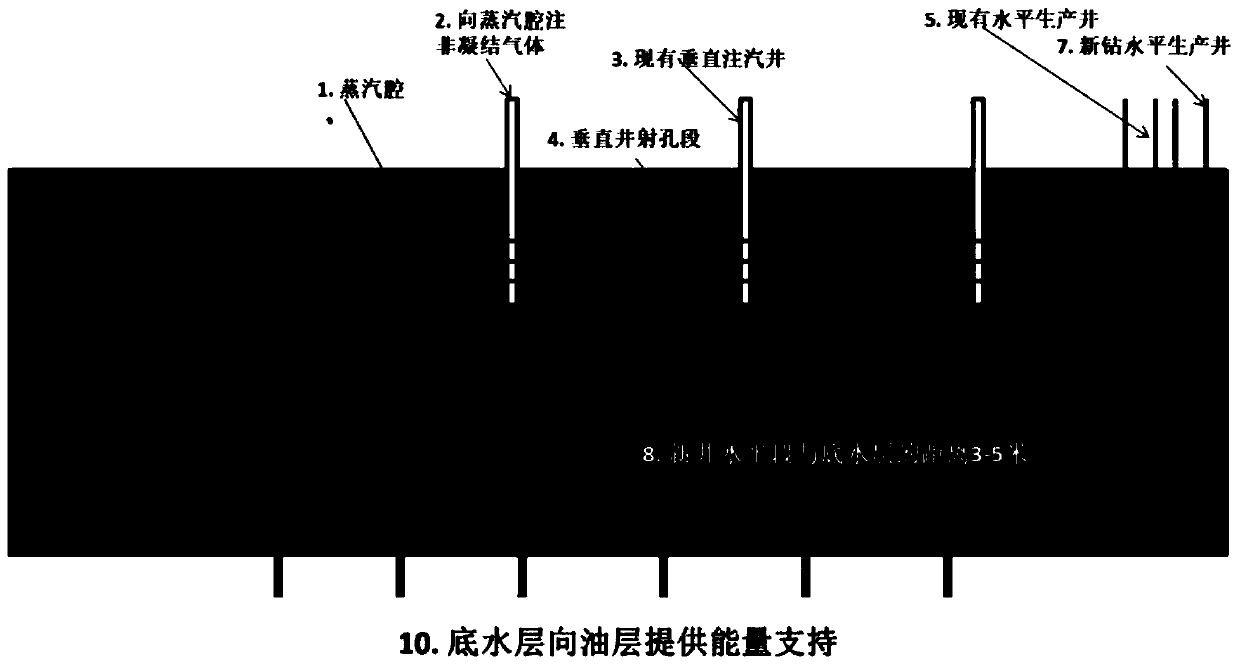

[0025] Such as Figure 2-5 Shown, the method for injecting non-condensable gas of the present invention or in-situ combustion exploitation bottom water heavy oil reservoir, comprises the following steps:

[0026] (1) Drill a new horizontal well in the oil layer between the existing horizontal production well position and the bottom water layer, and the horizontal well is located in the oil layer above the top of the bottom water layer 2-5m.

[0027] (2) Preheat the new horizontal well by any one of steam circulation, electric heating, solvent injection or any combination thereof; in this preheating stage, the operating pressure at the bottom of the well is equal to the pressure of the water layer to prevent the injection fluid from entering Bottom water layer; at the same time, inject air or flue gas into the steam cavity through the original vertical steam injection well to increase the pressure of the steam cavity to the same pressure as the bottom water.

[0028] (3) After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com