A pure water immersion corrosion test fixture and test device

A technology of corrosion experiment and infiltration device, which is applied in the direction of workpiece clamping device, measuring device, weather resistance/light resistance/corrosion resistance, etc. It can solve the problems that cannot meet the requirements of immersion corrosion test, and the pollution effect of pure water is large, so as to achieve low cost , high cost, the effect of preventing crevice corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

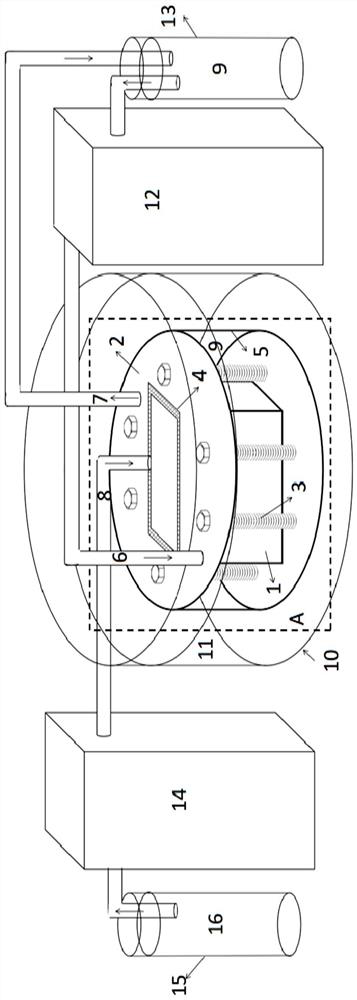

[0047] Using the device to conduct FeCl3 immersion corrosion test on 2205 stainless steel welded joints with reference to ASTM923 standard method C, the specific process is as follows:

[0048] 1. Use anhydrous alcohol to ultrasonically clean the surface of the sample to remove oil residue on the surface, dry it and weigh it.

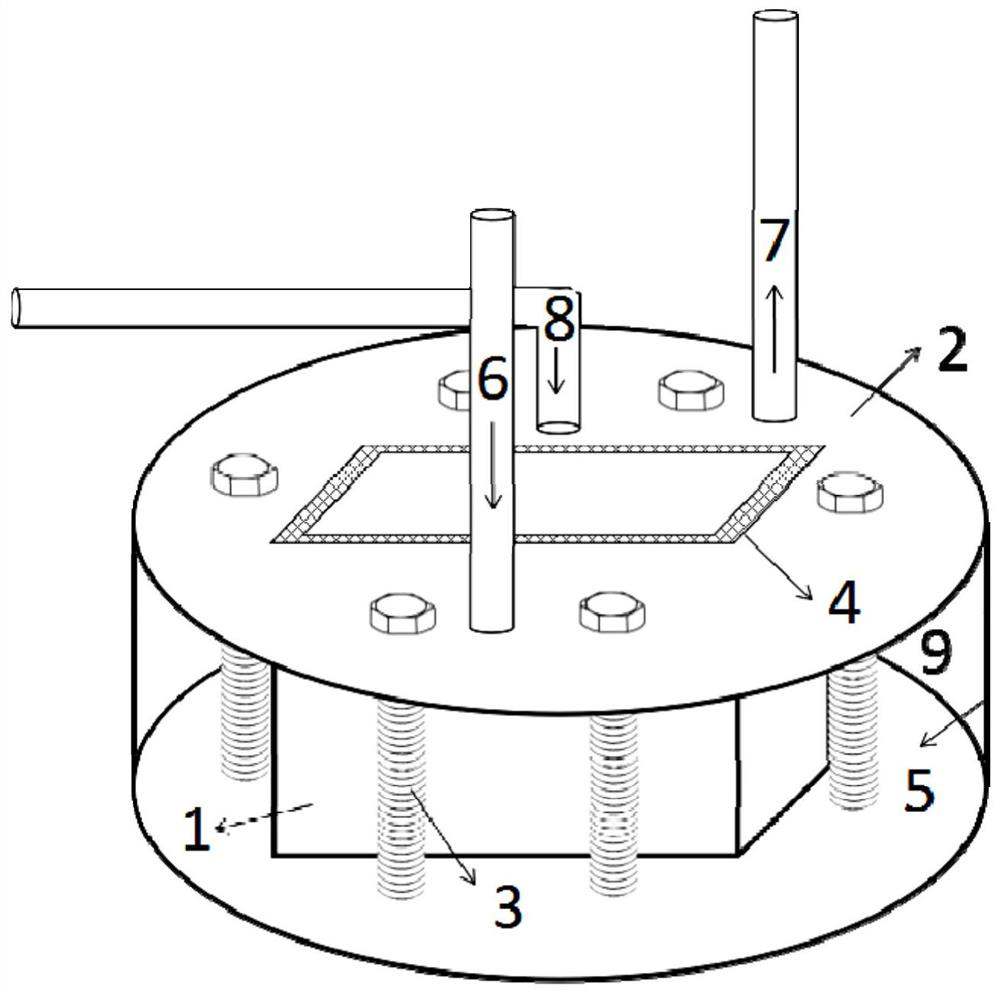

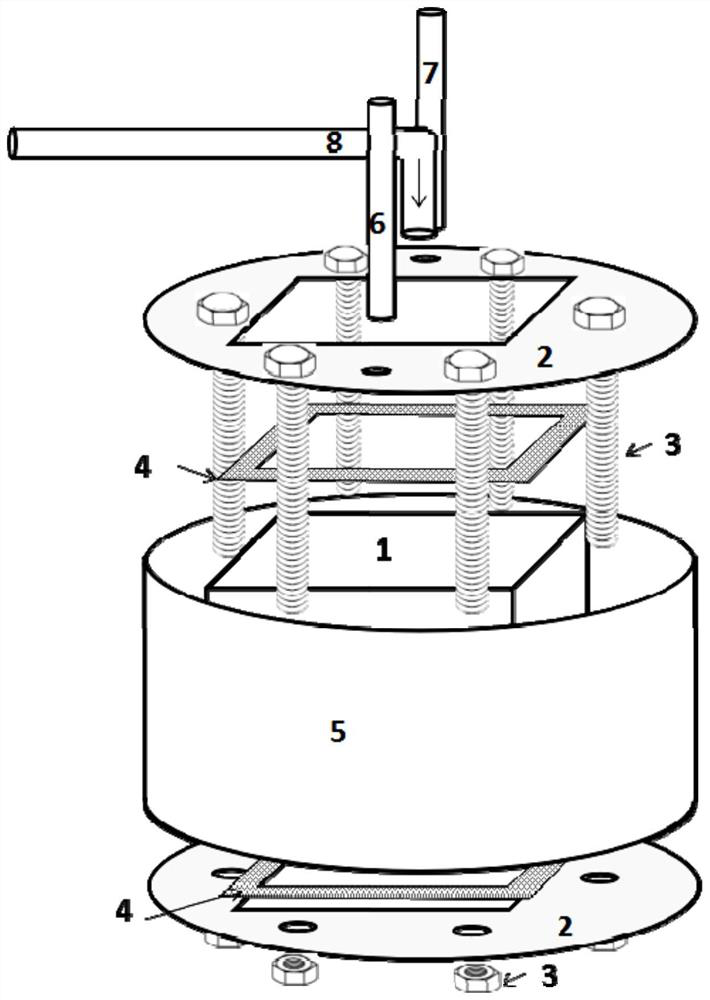

[0049] 2. Take two pieces of laboratory filter paper, cut a 25mm*50mm hole in the middle, and cover the upper and lower surfaces of the sample after wetting with pure water. Then place the sample between the upper and lower cover plates and tighten the fastening bolts.

[0050] 3. Put the flexible film between the upper and lower cover plates, and realize the sealed connection of the two through glue or other means, forming a closed pure water bag. Then connect the pure water pipe and inject the pure water pre-placed in the graduated cylinder into the bag through the delivery pump to realize circulation. After keeping it for 30 minutes, observe whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com