Off-site equipment remote maintenance monitoring platform system and monitoring method

A technology of remote maintenance and monitoring platform, applied in transmission system, digital transmission system, comprehensive factory control, etc., can solve the problem of inaccurate abnormal data alarm, and achieve the effect of accurate prediction value and high judgment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

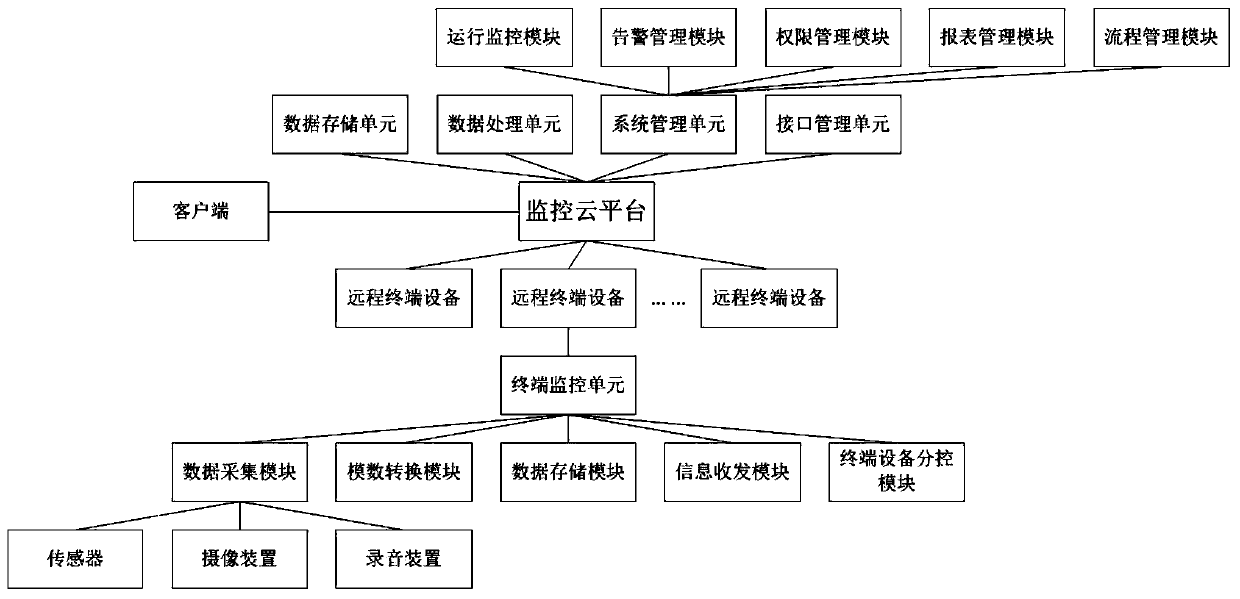

[0057] A remote maintenance and monitoring platform system for off-site equipment, such as figure 1 As shown, it includes several remote terminal devices distributed in different places, a local monitoring cloud platform, and a client; wherein the remote terminal device also includes a terminal monitoring unit, which can obtain information collected at the remote terminal device. running status information, and after performing analog-to-digital conversion on the running status information, the running status information is uploaded to the monitoring cloud platform in real time through the wireless network, and the monitoring cloud platform can perform data analysis after obtaining the running status information to obtain equipment condition analysis, The client can manage and monitor the monitoring cloud platform, and can receive equipment status analysis;

[0058] The terminal monitoring unit includes a data acquisition module, an analog-to-digital conversion module, a data ...

Embodiment 2

[0065] This embodiment is a supplementary description of Embodiment 1.

[0066] Since the terminal monitoring unit will obtain a large number of operating status information data of remote terminal equipment, it is necessary to implement numbering rules for the operating status information data. Considering that the present invention will distinguish each time period for data processing and analysis of the operating status information.

[0067] Then, let the historical operation state information data of the remote terminal equipment be UteBC, where U is the serial number of the remote terminal equipment, t is the serial number of each time period in a day, e is the daily date number in a month, and B is the serial number of each time period in a year Numbering. The t mentioned above divides 24 hours into a time period every 3 hours, that is, from 0:00 to 3:00 in a day, t is 1; from 3:00 to 6:00, t is 2; from 6:00 to 9:00, t from 9:00 to 12:00, t is 4; from 12:00 to 15:00, t ...

Embodiment 3

[0070] According to the numbering rules in Example 2, the abnormal data acquisition method described in Example 1 is specifically:

[0071] 1. Set the set of remote terminal equipment as U={u 1 ,u 2 ,...u u}, the running status information data collected by each remote terminal device in a period of time is I={i 1 ,i 2 ,...,i i}, the feature data is R;

[0072] Two, the feature data matrix R is decomposed into the form of the product of the equipment matrix U and the operation data matrix I, that is, R=UI, R=M×N, U=N×k, I=k×M;

[0073] 3. Assume that the difference between the real operating status information data and the predicted data obeys the Gaussian distribution, that is Equivalent to The objective function of matrix decomposition can be obtained by minimizing the above formula The L is the predicted value of the running state information data;

[0074] 4. After collecting the real value of the operating state information data, perform difference analysis wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com