Pharmaceutical composition comprising 2,5-dihydroxybenzenesulfonic acid or a pharmaceutically acceptable salt thereof in the form of personalised supply units and corresponding manufacturing method

A technology of dihydroxybenzene sulfonic acid and supply unit, which is applied in the directions of drug combination, anhydride/acid/halide active ingredient, pill delivery, etc., can solve the problem of not being able to ensure immediate effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

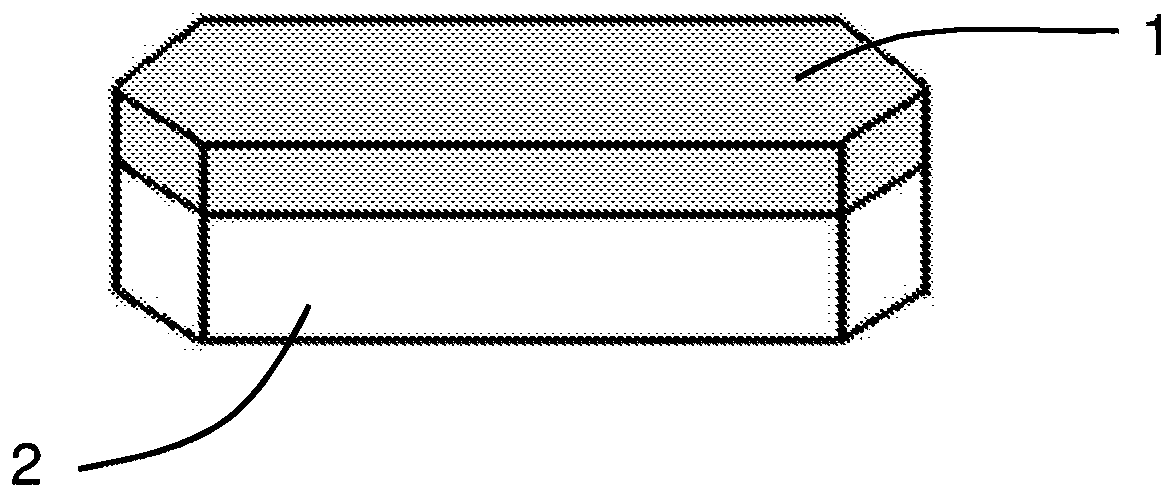

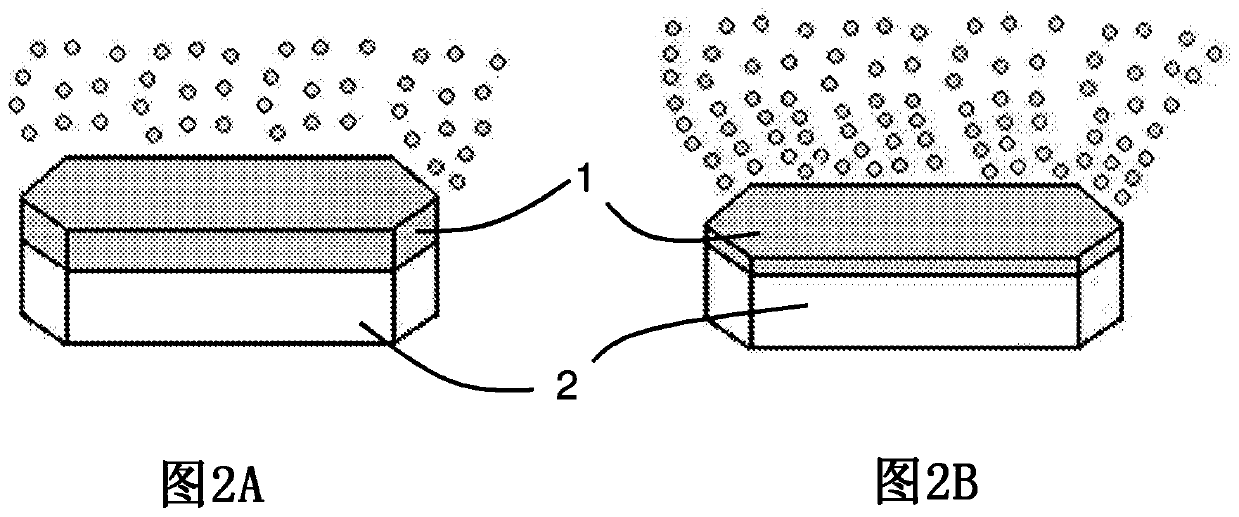

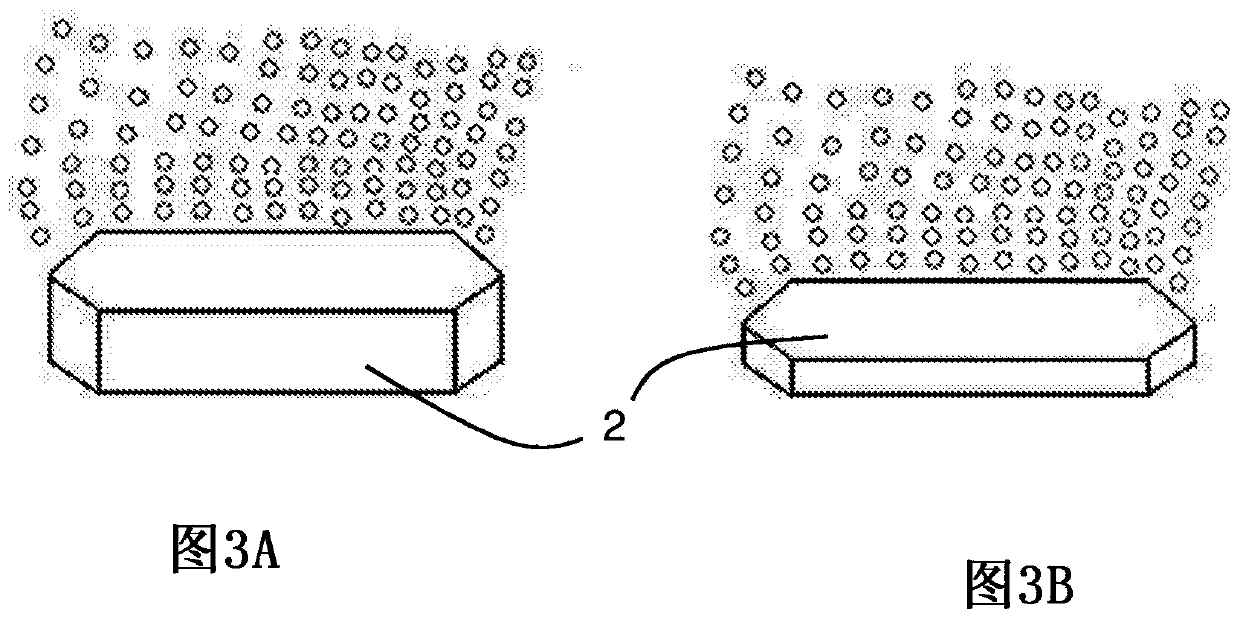

Image

Examples

Embodiment 1

[0150] The programmed release drug preparation process will be divided into the following two steps.

[0151] Step 1: Fabricate the Immediate Release Layer

[0152] a) 74.07% w / w calcium dobesilate, 20.74% w / w microcrystalline cellulose and 2.07% w / w sodium starch glycolate were sieved through a #20 sieve. All percentages are based on the total weight of the immediate release step.

[0153] b) Mixing the substances obtained in a) within a time interval of 1 minute to 30 minutes.

[0154] c) Sieve 1.33% w / w magnesium stearate and 1.78% w / w talc through a #30 sieve. All percentages are based on the total weight of the immediate release step.

[0155] d) Mixing the substances obtained in b) and c) within a time interval of 1 minute to 15 minutes.

[0156]

[0157] Step 2: Fabricate the Extended Release Layer

[0158] a) 53.76% w / w calcium dobesilate was micronized. All percentages are based on the total weight of the extended release step.

[0159] b) Dissolve 0.81%...

Embodiment 2

[0173] Step 1: Fabricate the Immediate Release Layer

[0174]

[0175] Step 2: Fabricate the Extended Release Layer

[0176]

[0177] * evaporates during the process

[0178] Both stages are compressed in the elongated punch. The ratio between the immediate release layer and the extended release layer was 31:69.

Embodiment 3

[0180] Step 1: Fabricate the Immediate Release Layer

[0181]

[0182] Step 2: Fabricate the Extended Release Layer

[0183]

[0184] * evaporates during the process

[0185] Both stages are compressed in the elongated punch. The ratio between the immediate release layer and the extended release layer is 34:66.

[0186] Figure 5 Release profiles of bilayer tablets are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com