Mould weight fastening device and method for casting assembly line resin sand

A technology of fastening device and assembly line, which is applied to the equipment for transporting casting molds, casting molding equipment, mold boxes, etc., to achieve the effect of simple structure, preventing castings from lifting the box, and satisfying the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

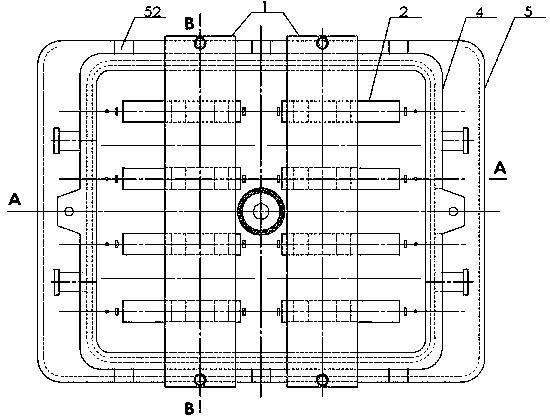

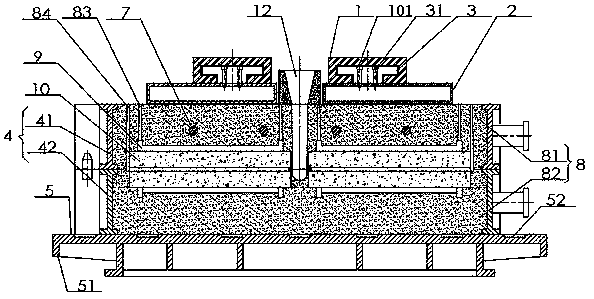

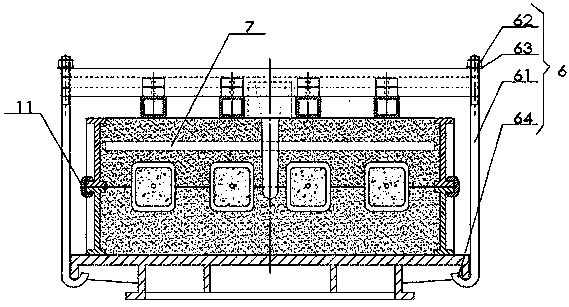

[0034] A preferred embodiment of a pressing iron fastening device and method for an assembly line resin sand casting mold according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] Such as figure 1 , figure 2 , image 3 As shown, the pressing iron fastening device used for assembly line resin sand casting molds includes 2 beams 1, 8 pressing plates 2 and 8 fixing blocks 3, 1 upper sand box mold 81 and 1 lower sand Box casting, a pouring bottom plate, 4 pieces of Φ30mm steel movable box block, 2 sets of M28 bolts and studs to fasten the structure.

[0036] Such as Figure 4 , Figure 5 As shown, according to the arrangement of the casting molds, adjust the positions of the four pressure plates 2 on the beam 1 so that they face each casting cavity 9 and avoid the air outlet piece 83 or air outlet needle 84 of the upper sand box mold 81 . Place the beam 1 with the pressure plate 2 on both sides of the sprue c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com