Automatic machining method of thin-wall hemispherical shell

A processing method and hemispherical technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of poor material chip breaking effect and affect the stability of automatic turning process, and achieve good chip breaking effect and stability. chip breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

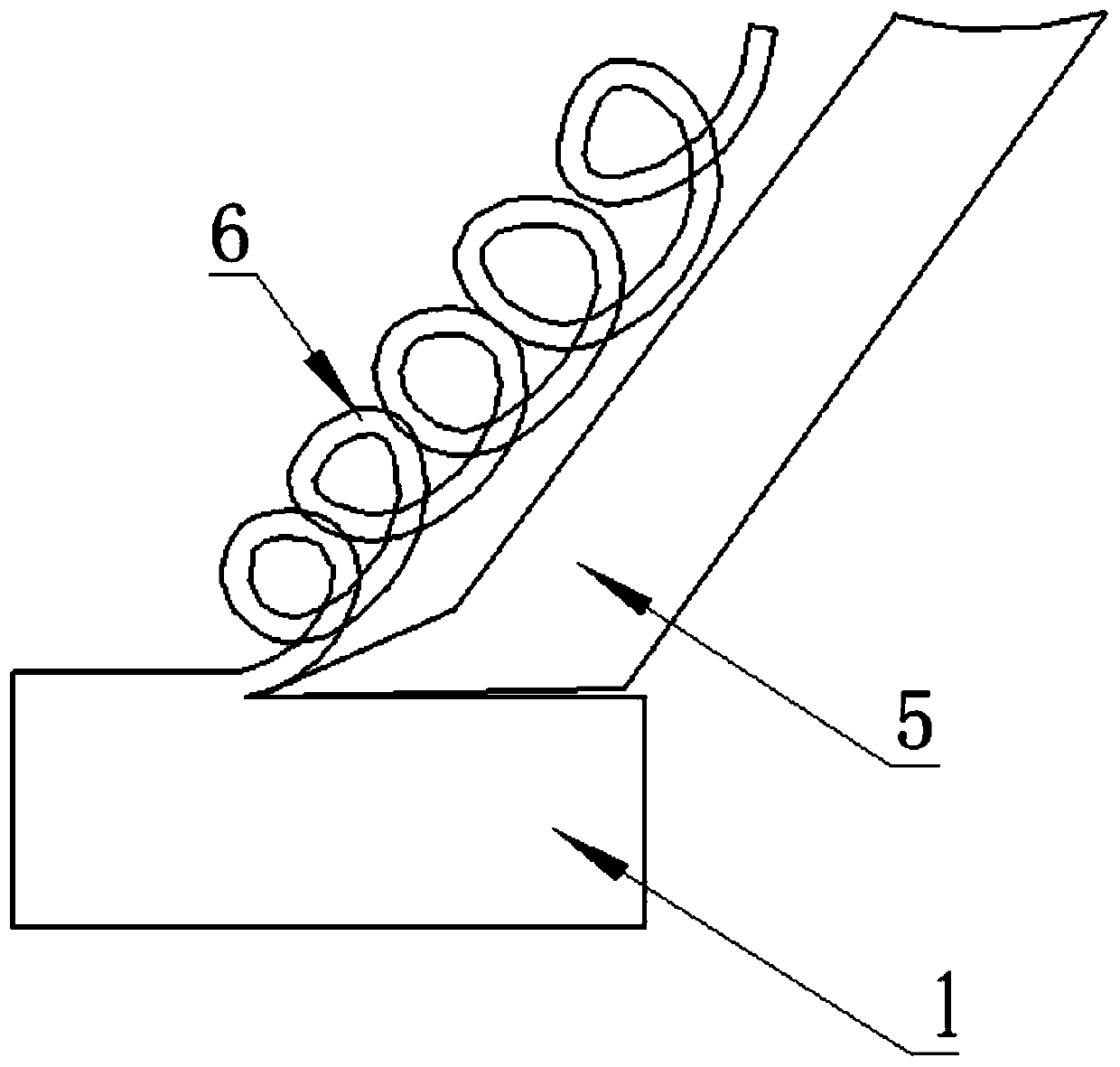

[0038] Such as figure 2 As shown, the requirements for automatic turning chip breaking are to ensure the physical, mechanical properties and surface quality of the workpiece after it is processed into parts; to ensure the safety of the operator without damaging the machine tool; to ensure the service life of the tool 5; to ensure reliable chip breaking and not to be entangled with each other . The commonly used chip breaking methods are tool chip breaker chip breaking, mechanical device chip breaking, energy (light energy, thermal energy, electric energy, vibration) chip breaking.

[0039] The chip breaking of the tool chip breaker needs to change the tool structure, which will bring other problems, such as reducing the surface quality of the workpiece; for materials with better plasticity, no matter how the structure of the tool edge is changed, the chip breaking cannot be effective. Other chip breaking methods require complex structures and equipment, poor stability, great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com