An electromagnetic field assisted laser cutting method

A technology that assists laser and cutting methods. It is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., and can solve the problems that cutting cannot continue, molten metal reverse spraying, etc., so as to improve the cutting effect, avoid reverse spraying, and avoid " The effect of reverse spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

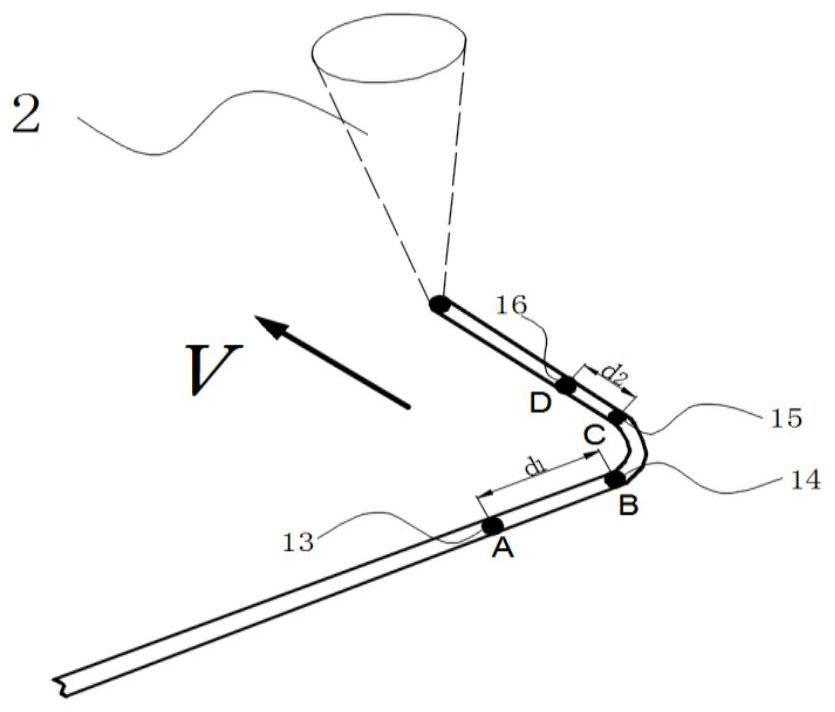

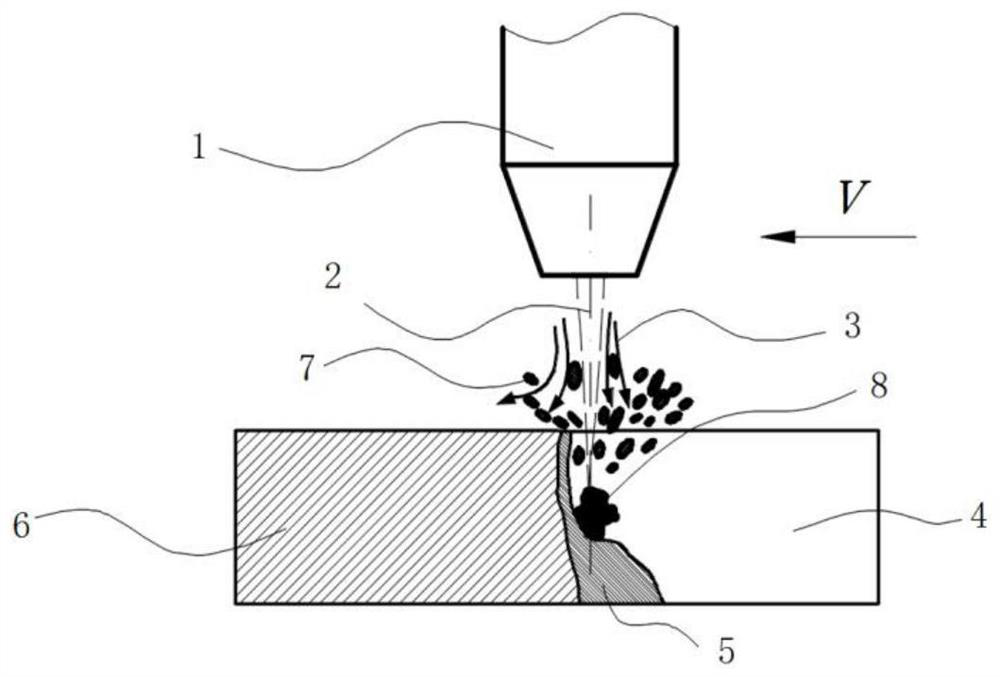

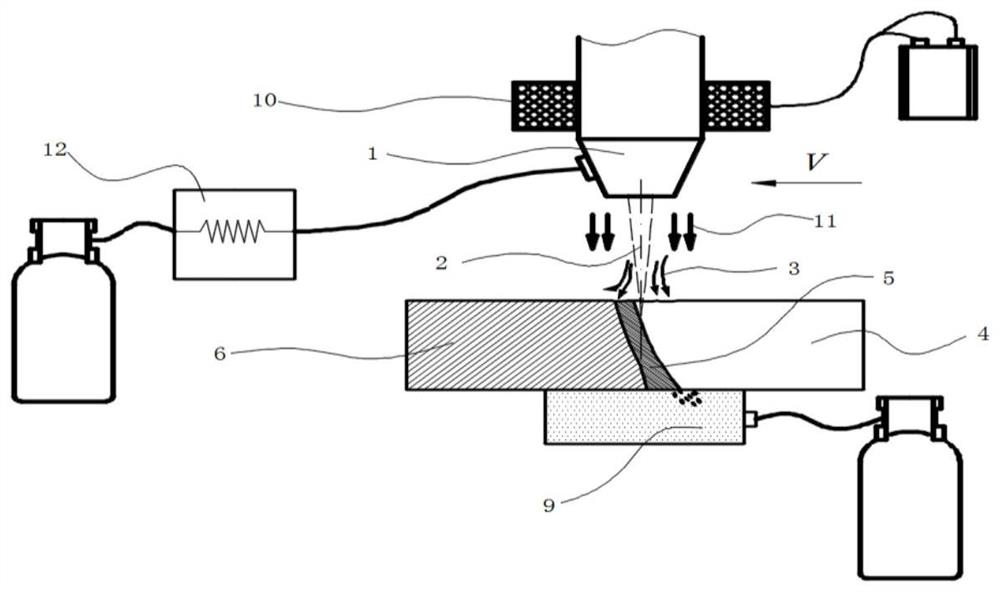

[0038] The following is attached Figure 1~4 And specific embodiments to illustrate the technical solutions of the present invention in detail.

[0039] Such as Figure 1~4 As shown, in the embodiment of the present invention, an electromagnetic field assisted laser cutting method includes the following steps.

[0040] Step 1: Fix the electromagnetic coil 10 on the laser cutting head 1, and it can move with the laser cutting head 1.

[0041] In this embodiment, the electromagnetic field generated when the electromagnetic coil 10 is activated is 0.1-5 T.

[0042] Step 2: Arrange the gas heating device 12 in the cutting assist gas gas path.

[0043] In this embodiment, nitrogen is selected as the cutting auxiliary gas, with a purity of 99.999%.

[0044] Step 3: Place the bottom shielding gas device 9 under the corner of the workpiece to be cut.

[0045] In this embodiment, the workpiece to be cut is a stainless steel plate with a thickness of 15-30 mm.

[0046] Such as figure 1 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com