A dry-hanging system for fast-installing stone on the wall

A stone dry-hanging and stone technology, which is applied in covering/lining, construction, building construction, etc., can solve the problems of complicated procedures, low efficiency, and large pollution, and achieve simplified procedures, high functional integration, and reduced dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

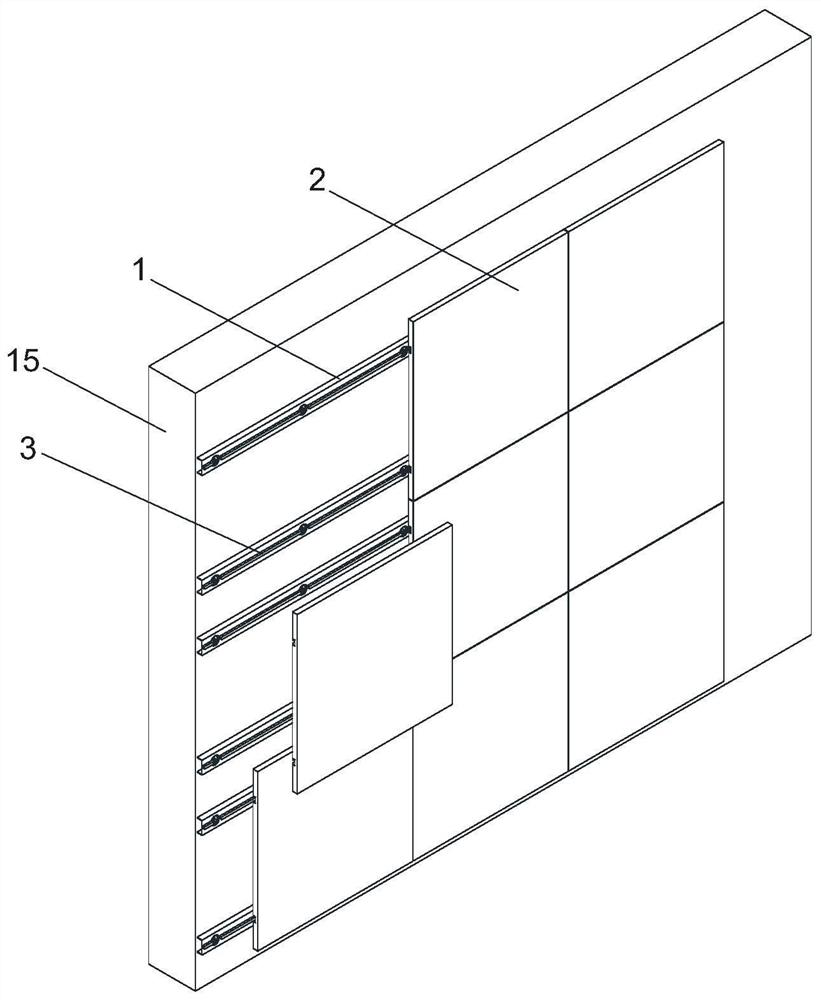

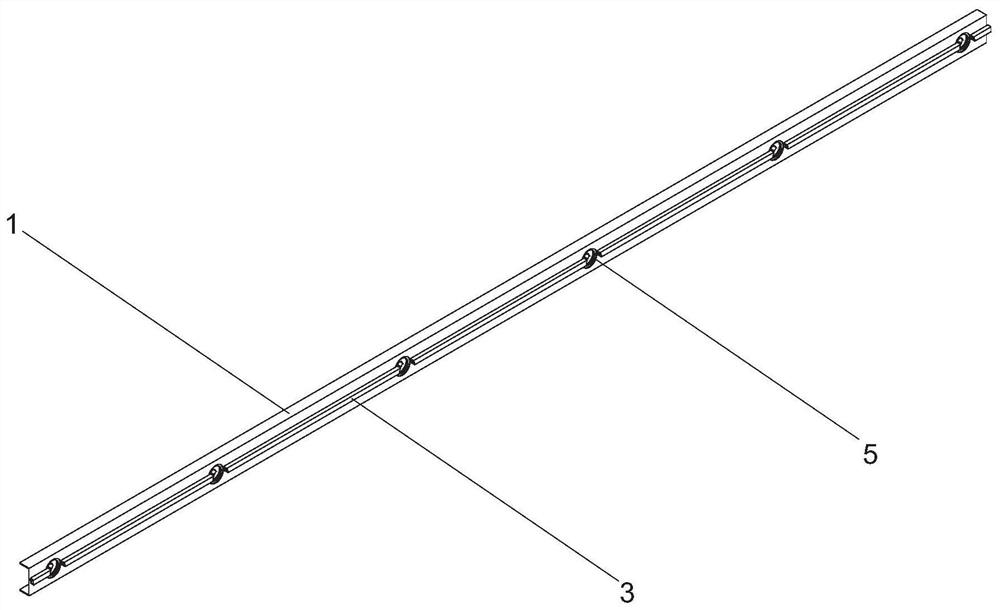

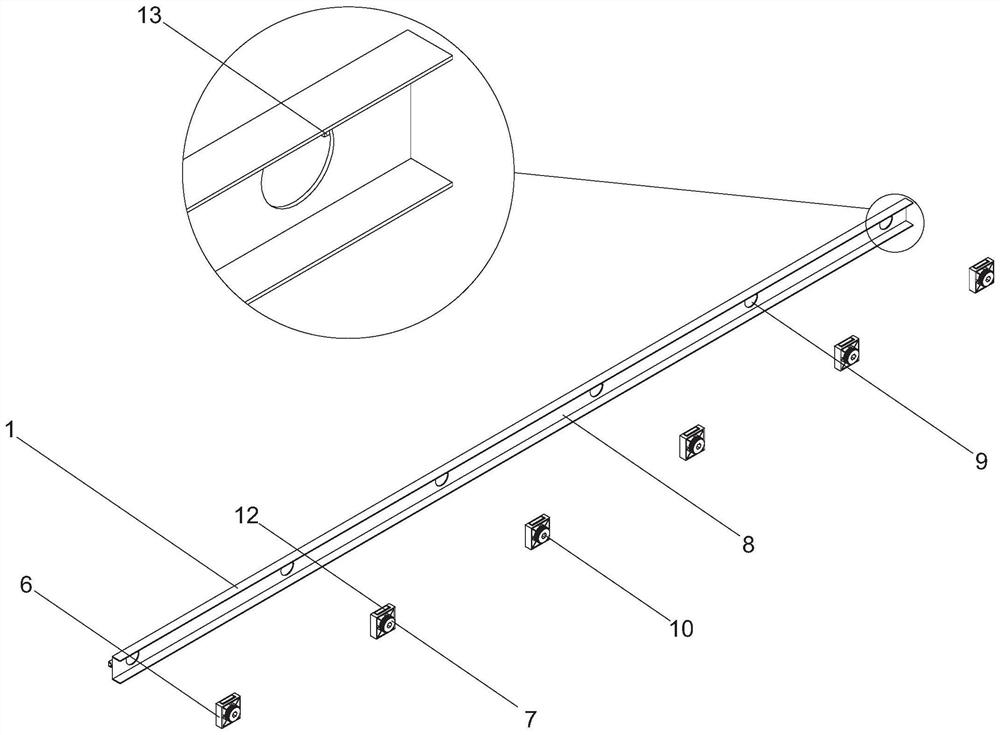

[0027] Such as Figure 1 to Figure 7 As shown, a dry-hanging system for quick installation of stone on the wall includes an installation keel 1 and stone materials 2, the installation keel 1 is installed on the wall, and the installation keel 1 is provided with a stone hanging body 3, and the stone hanging body 2 and the installation The keel 1 is integrally formed, the back of the stone 2 is embedded with a prefabricated strip 11, the prefabricated strip 11 is provided with a hanging notch 4, the hanging notch 4 traverses both ends of the stone 2, and the hanging notch 4 is adapted to connect with the stone hanging body 3. The cross section of the hanging notch 4 is C-shaped. The opening of the hanging notch 4 is provided with a symmetrical closing edge 14. The closing edge 14 is formed by buckling and bending the prefabricated strip 11 at the outer end of the hanging notch 4. The closing edge 14 It forms a hook structure with the side of the prefabricated strip 11. The pref...

Embodiment 2

[0030] There are three hanging notches 4 on each stone 2 and they are parallel and evenly distributed on the back of the stone 2 . There are six through holes 9 on each keel 1 for installation. The central hole 10 is square. All the other are with embodiment 1.

Embodiment 3

[0032] There are four hanging notches 4 on each stone 2 and they are parallel and evenly distributed on the back of the stone 2 . There are seven through holes 9 on each keel 1 for installation. The central hole 10 is a regular pentagon. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com