Taper clutch brake device

A brake device and taper technology, which is applied in the field of clutches, can solve the problems of increasing the safety risk of processing equipment, the shaft cannot be stopped quickly, and the single function, so as to improve transmission efficiency and braking efficiency, improve processing efficiency, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] This clutch brake device is mainly aimed at the improvement of clutches or reducers in various processing and manufacturing equipment manufactured in the existing industry, but for its integrated function of clutch and brake, this structure is not limited to be used in processing Or manufacturing equipment, but also applicable to other fields such as automobiles.

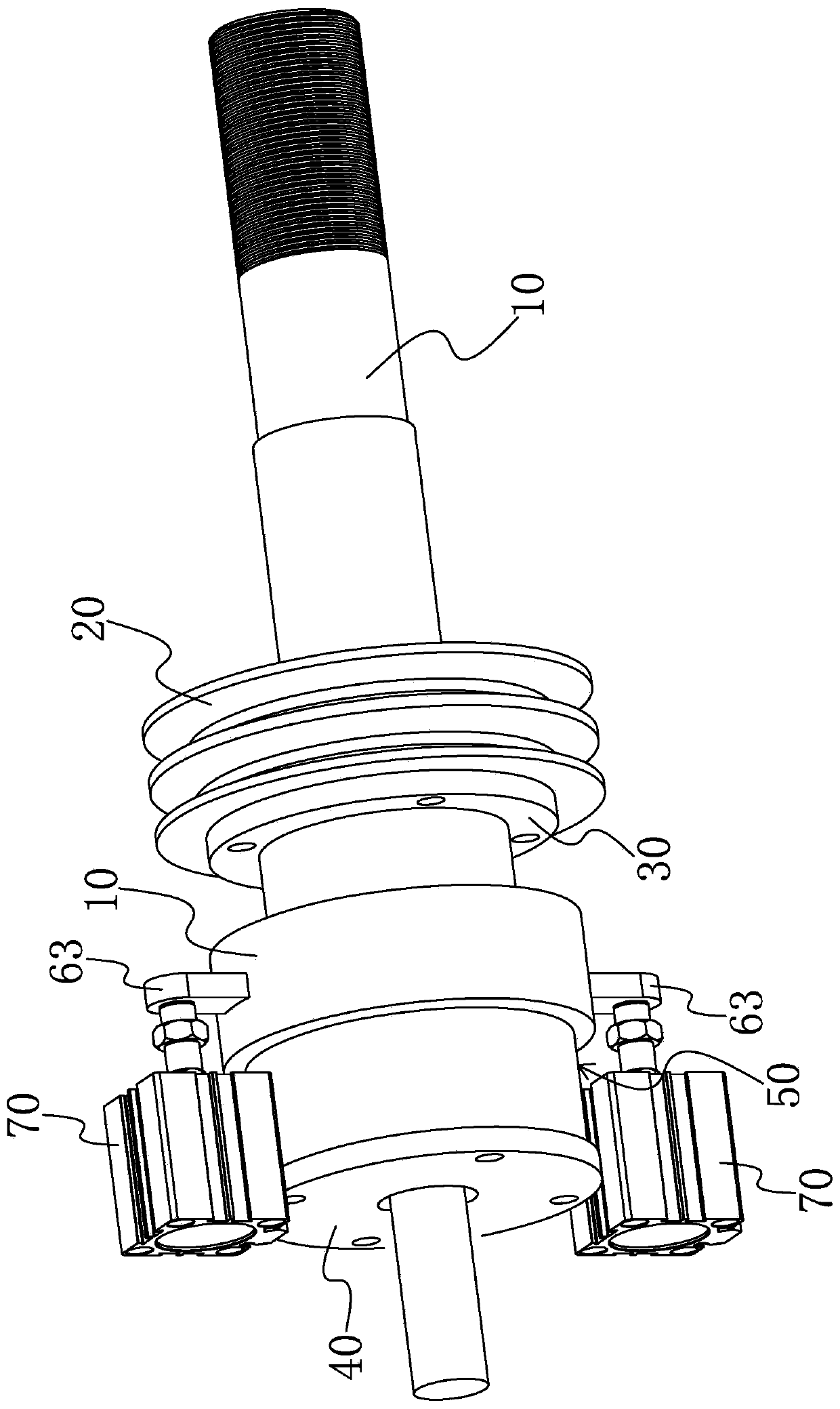

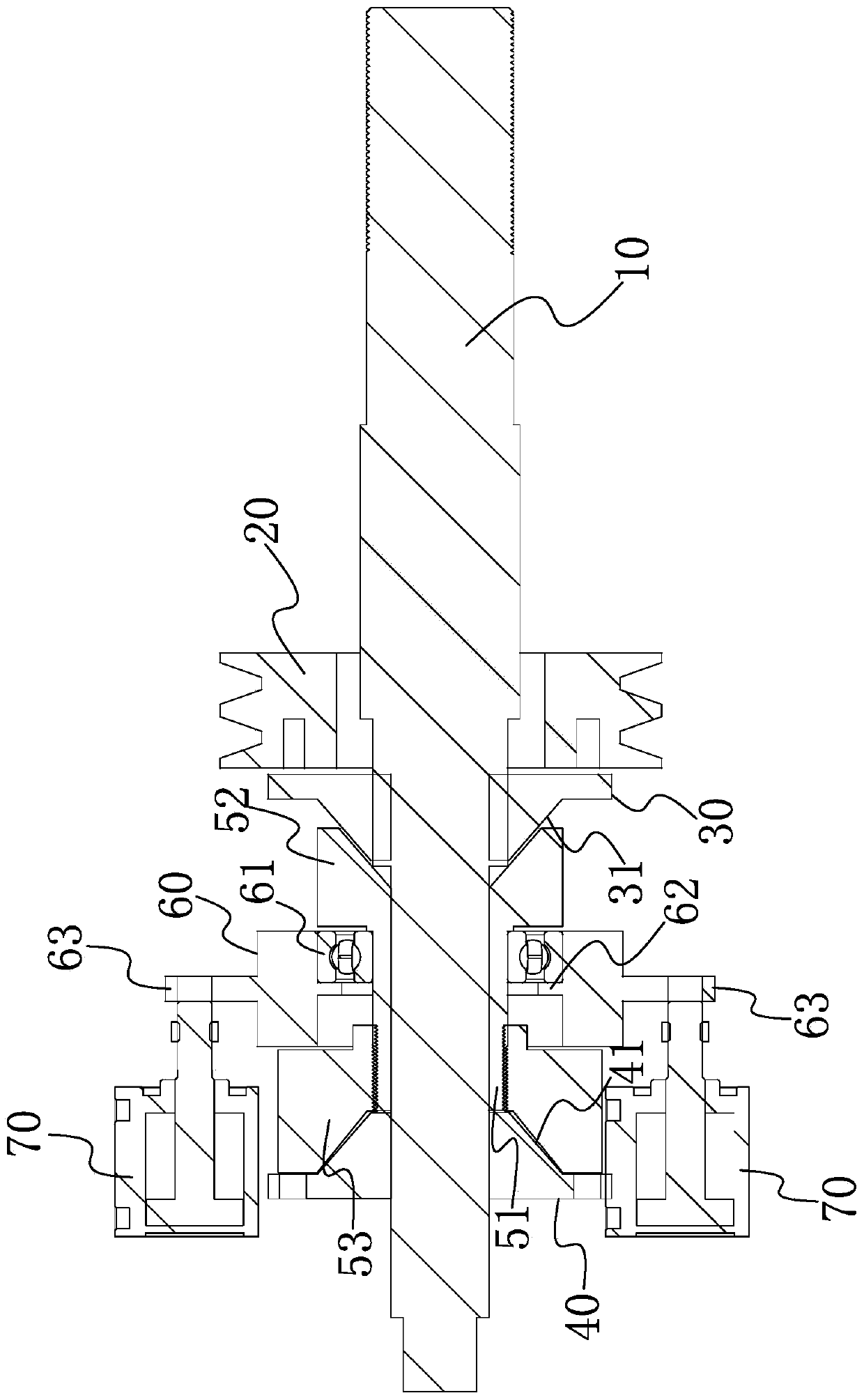

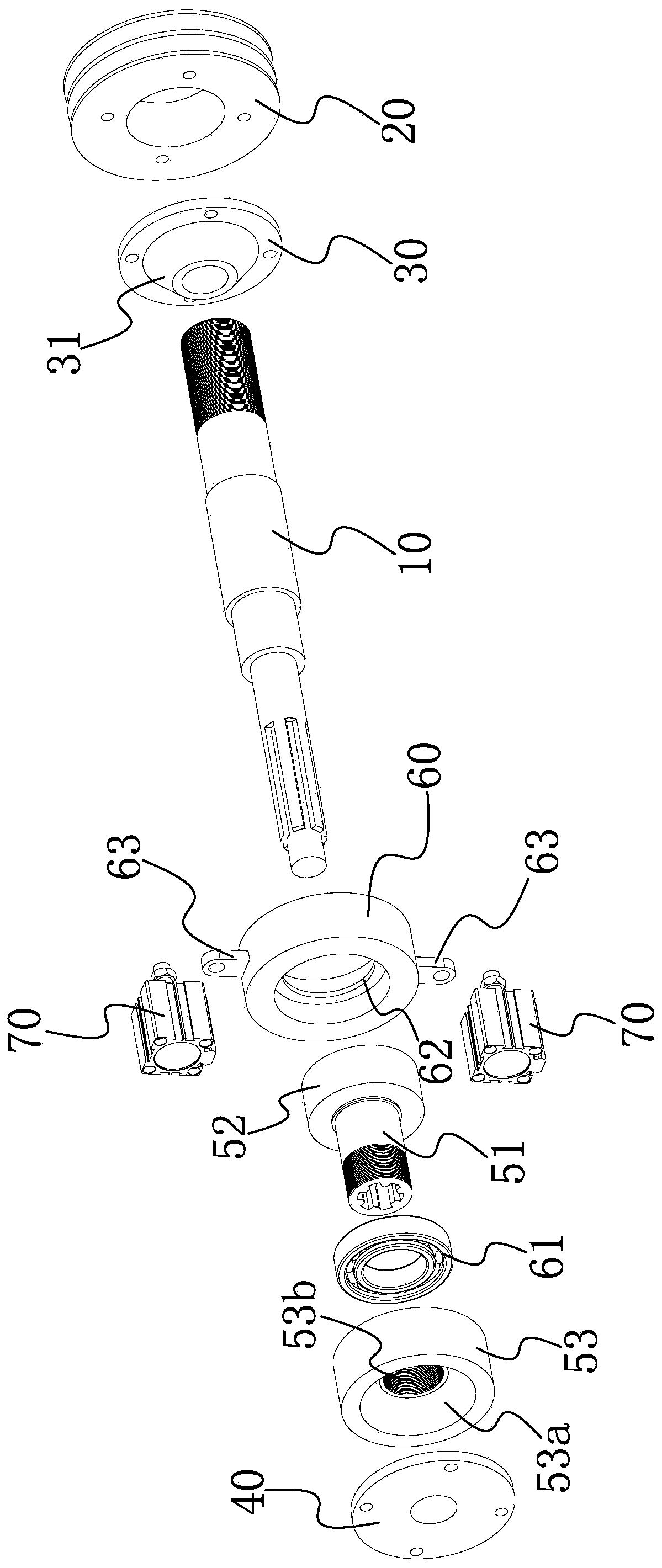

[0036] Such as Figure 1-Figure 4 As shown, a taper clutch braking device of the present invention mainly includes a transmission shaft 10 , a driving wheel 20 , a transmission seat 30 , a brake seat 40 and a transmission member 50 .

[0037] The transmission shaft 10 is axially extended, and the driving wheel 20 is installed on the transmission shaft 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com