Strong impact test adjusting device and method suitable for carrier-based electronic equipment

A technology for impact testing and electronic equipment, which is applied in the direction of impact testing, measuring devices, and testing of machine/structural components, etc. It can solve problems such as under-testing, inconsistency between impact-resistant design input indicators and impact assessment test values, and equipment over-testing. , to achieve the effect of improving equipment and facilitating shipboard electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further elaborated below.

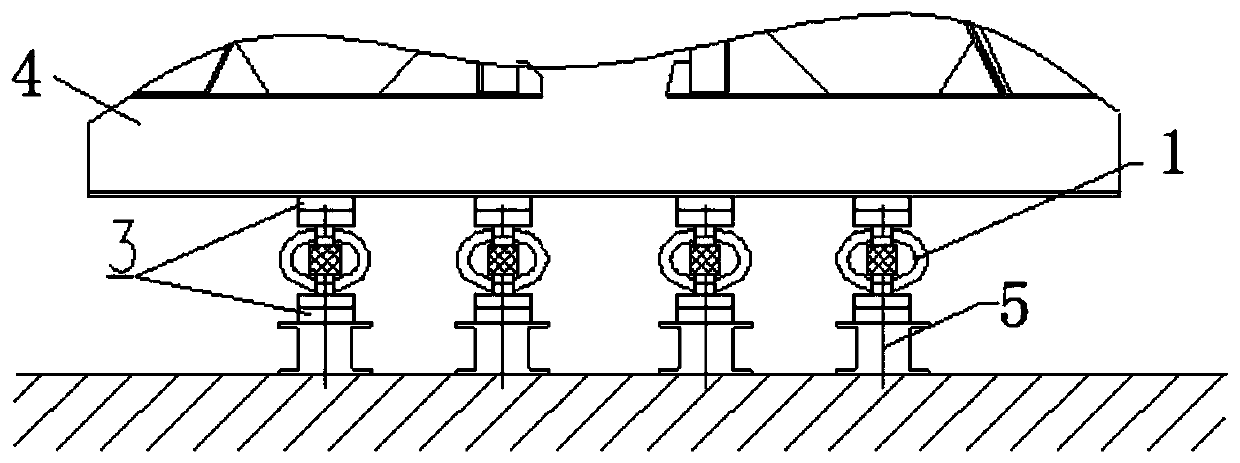

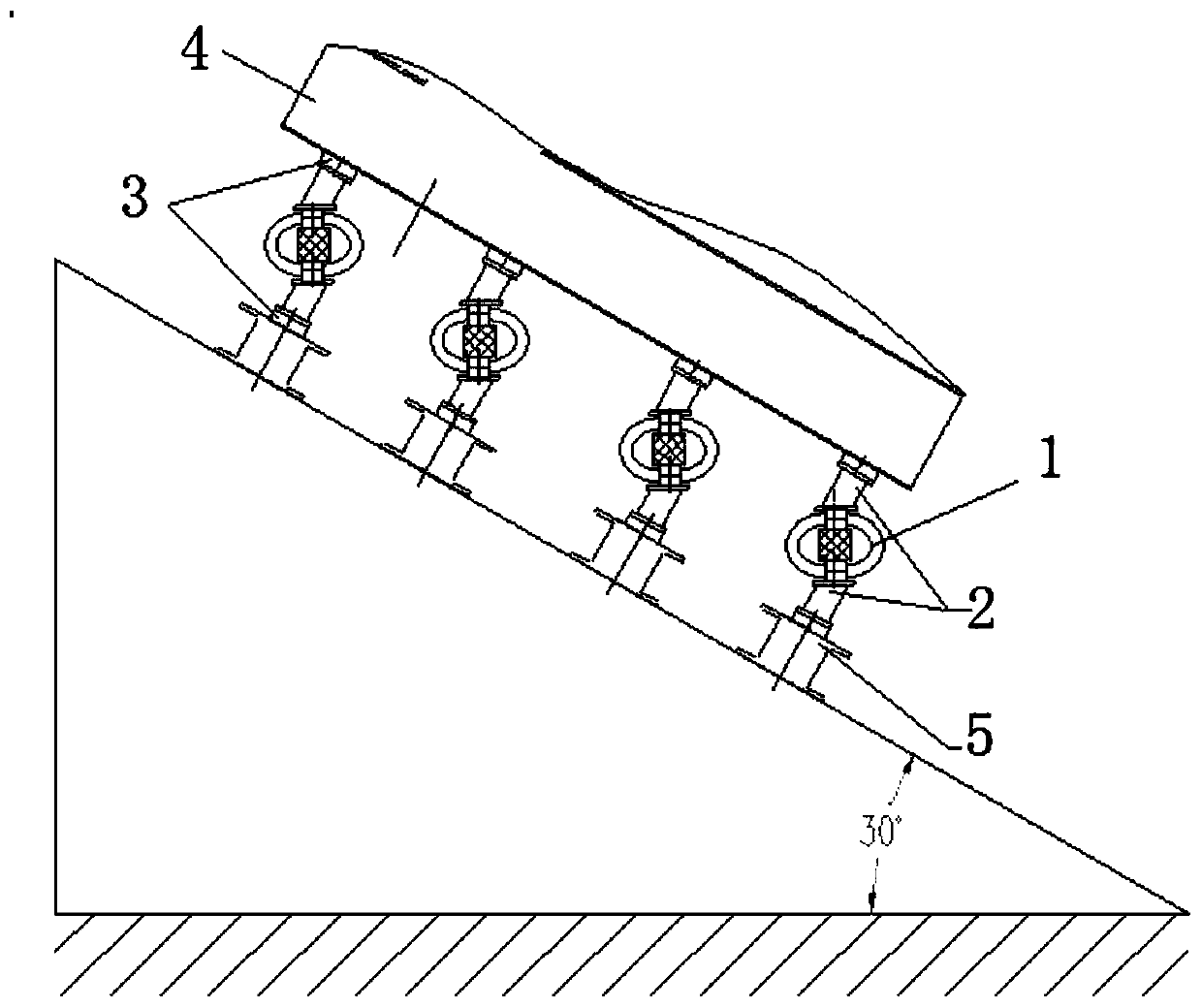

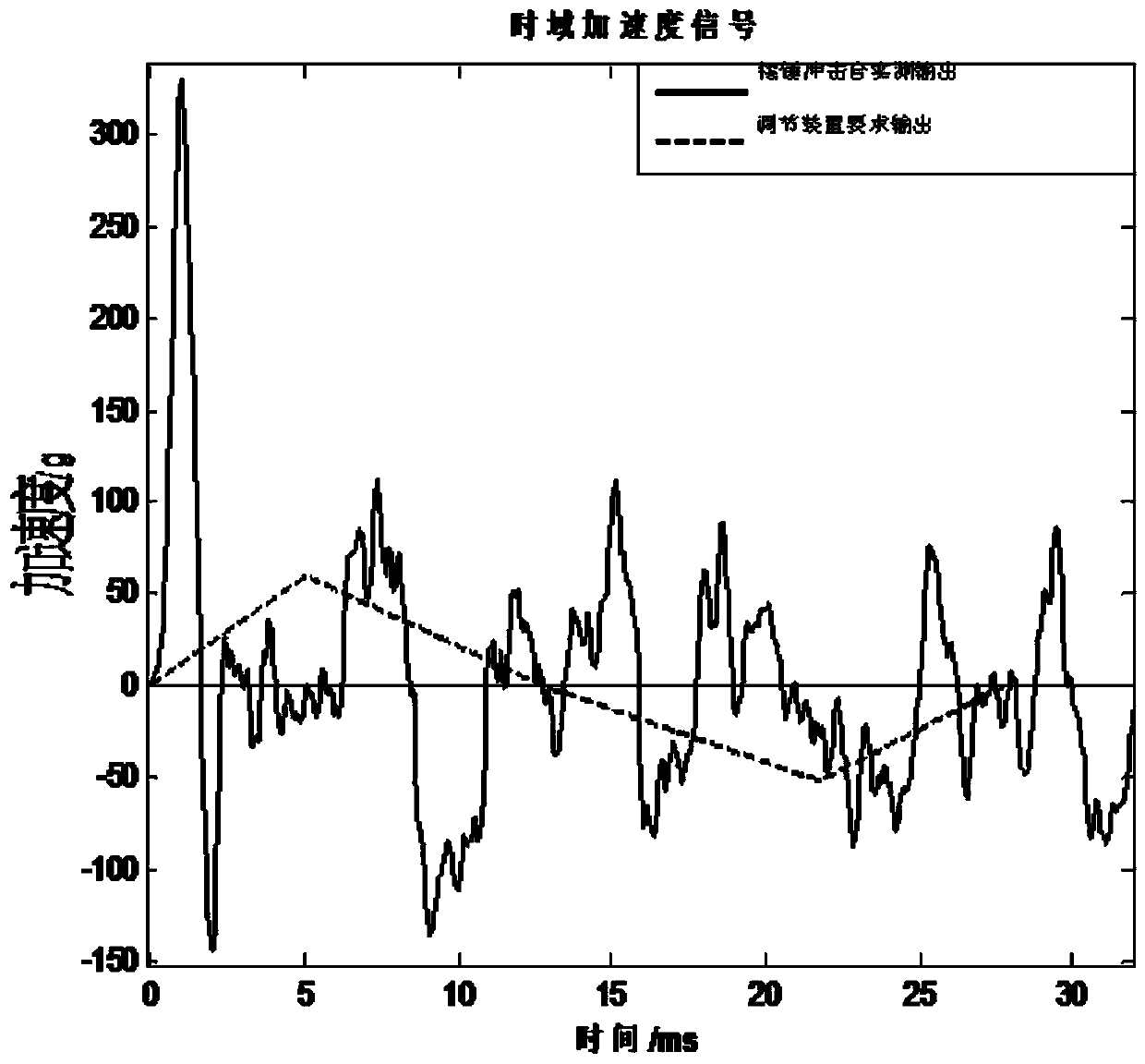

[0075] Such as Figures 1 to 7-2 As shown, the present invention provides a strong impact test adjustment device suitable for shipboard electronic equipment, including an adjustment module 1 , a transition bracket 2 , and a connecting plate 3 . The adjustment module 1 includes a wire rope shock absorber 10 , a rubber plate 11 and a steel plate 12 . A steel plate 12 is installed in the length direction of the wire rope damper 10, and rubber plates 11 are arranged above and below the steel plate 12. The steel plate 12 is connected with the wire rope damper through the rubber plate 11. The steel plate 12 and the rubber plate 11 fill the wire rope damper 10 vertically. direction. The equipment under test is connected to the transition bracket 2 through a connecting plate 3 , and the test bench is connected to another transition bracket 2 through another connecting plate 3 ; the adjustment module 1 is connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com