Lubricating oil moisture content measuring system and method based on Rafal spray pipe

A Rafal nozzle and measurement system technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of inability to realize online detection, and achieve the effects of easy online monitoring, high measurement accuracy, and accurate moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

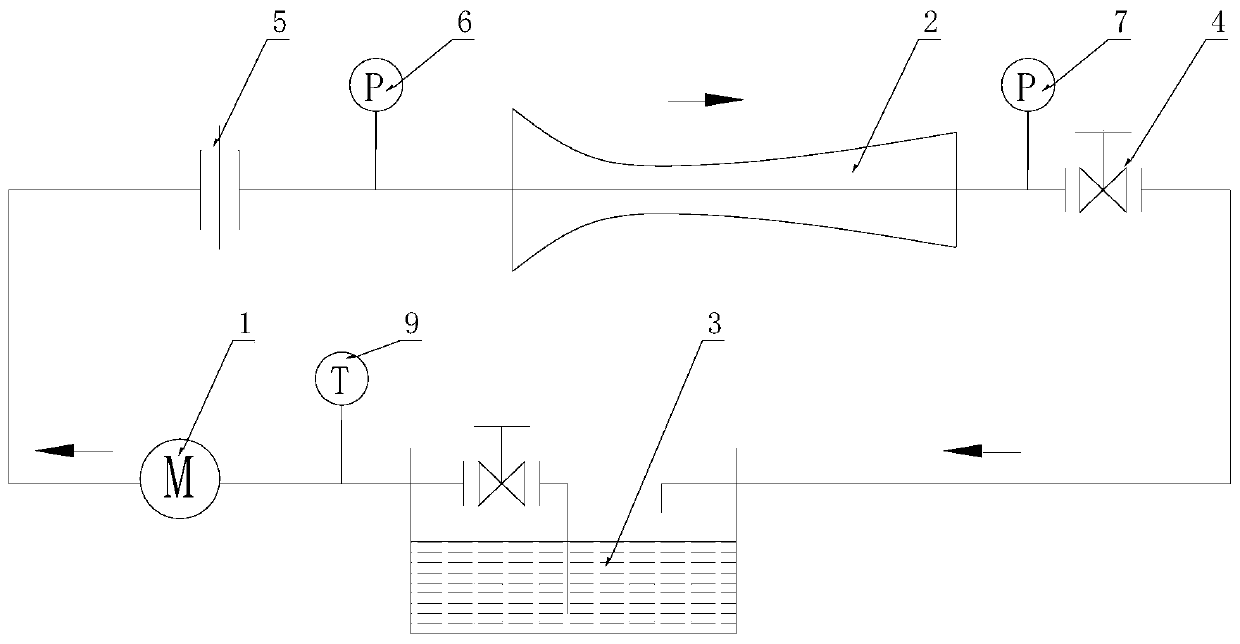

[0038] Such as Figure 1-2 Shown, a kind of lubricating oil moisture content measuring system based on Rafal nozzle, comprises oil pump 1, Rafal nozzle 2 and lubricating oil tank 3, the inlet of described oil pump 1 is connected the outlet of lubricating oil tank 3 through pipeline, and oil pump The outlet of 1 is connected to the inlet of Rafal nozzle 2 through a pipeline, and the outlet of Rafal nozzle 2 is connected to the inlet of lubricating oil tank 3 through a pipeline, and the lubricating oil flows back to lubricating oil tank 3 after passing through oil pump 1 and Rafal nozzle 2 constitute a cycle.

[0039] A first valve 4 is provided between the outlet of the Rafal nozzle 2 and the inlet of the lubricating oil tank 3 .

[0040] A flowmeter 5 and a first pressure gauge 6 are arranged on the pipeline between the inlet of the Rafael nozzle 2 and the outlet of the oil pump 1, and a second pressure gauge7.

[0041] A temperature sensor 9 is provided on the pipeline bet...

Embodiment 2

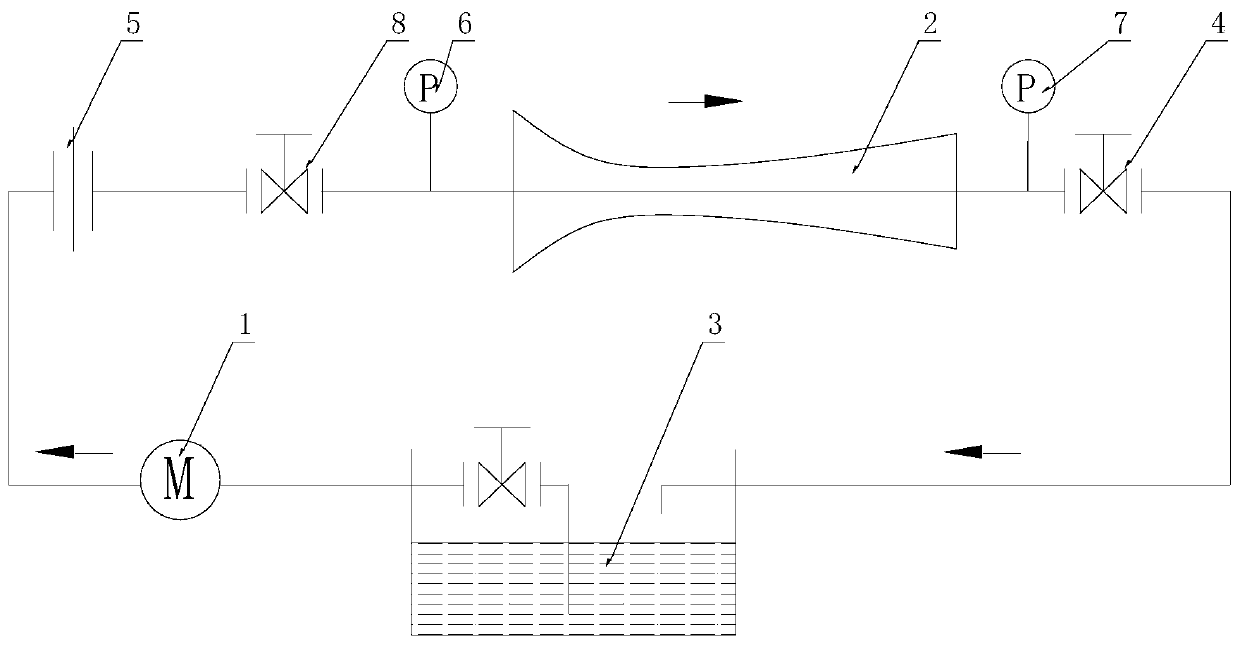

[0063] Such as image 3 Shown, a kind of lubricating oil moisture content measuring system based on Rafal nozzle, comprises oil pump 1, Rafal nozzle 2 and lubricating oil tank 3, the inlet of described oil pump 1 is connected the outlet of lubricating oil tank 3 through pipeline, and oil pump The outlet of 1 is connected to the inlet of Rafal nozzle 2 through a pipeline, and the outlet of Rafal nozzle 2 is connected to the inlet of lubricating oil tank 3 through a pipeline, and the lubricating oil flows back to lubricating oil tank 3 after passing through oil pump 1 and Rafal nozzle 2 constitute a cycle.

[0064] A second valve 8 is provided on the pipeline between the inlet of the Rafael nozzle 2 and the outlet of the oil pump 1 , and a first valve 4 is provided between the outlet of the Rafael nozzle 2 and the inlet of the lubricating oil tank 3 .

[0065] A flowmeter 5 and a first pressure gauge 6 are arranged on the pipeline between the inlet of the Rafael nozzle 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com