Airborne electronic module plugging locking puller

An electronic module and puller technology, which is applied to the installation of printed circuit board sockets, support structures, etc., can solve the problem that the puller cannot take into account the module locking, etc., so as to save maintenance time and cost, reduce design weight, fast installation and The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

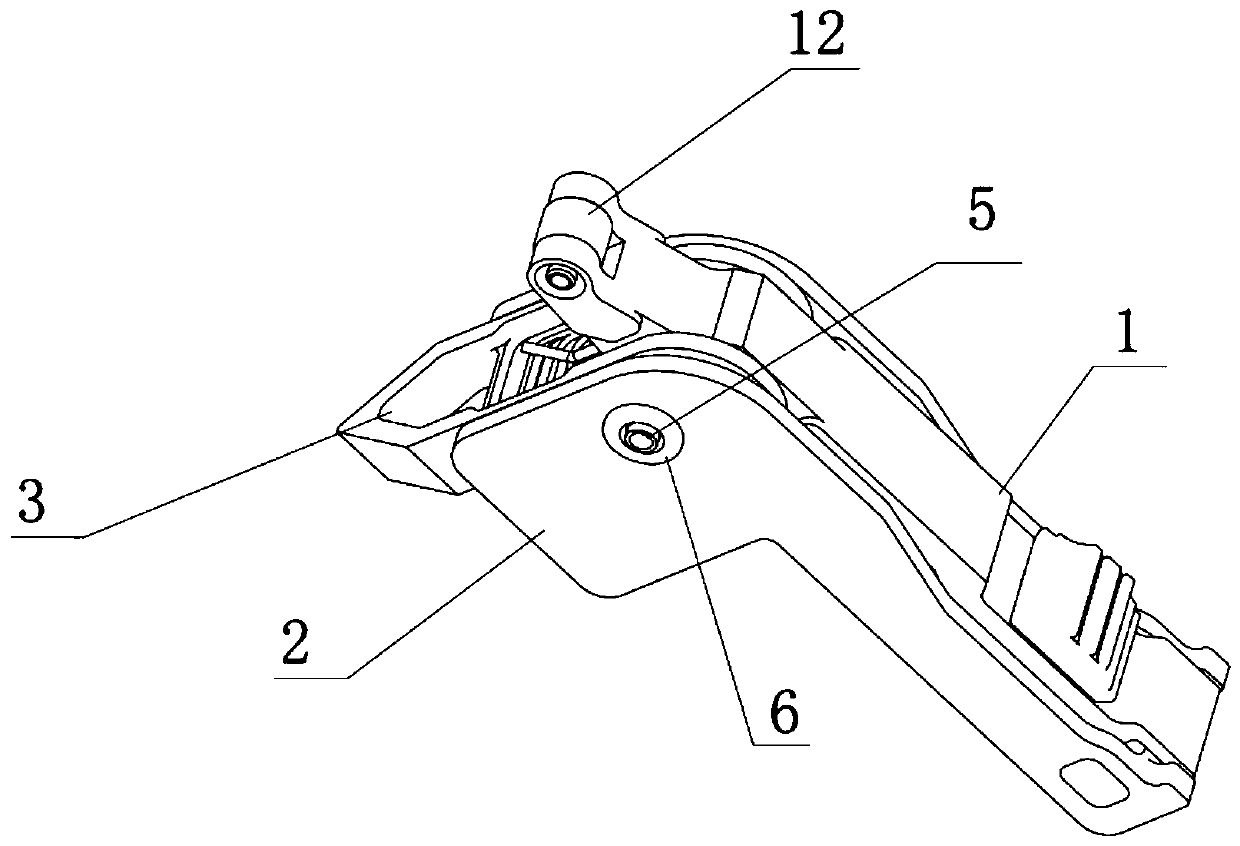

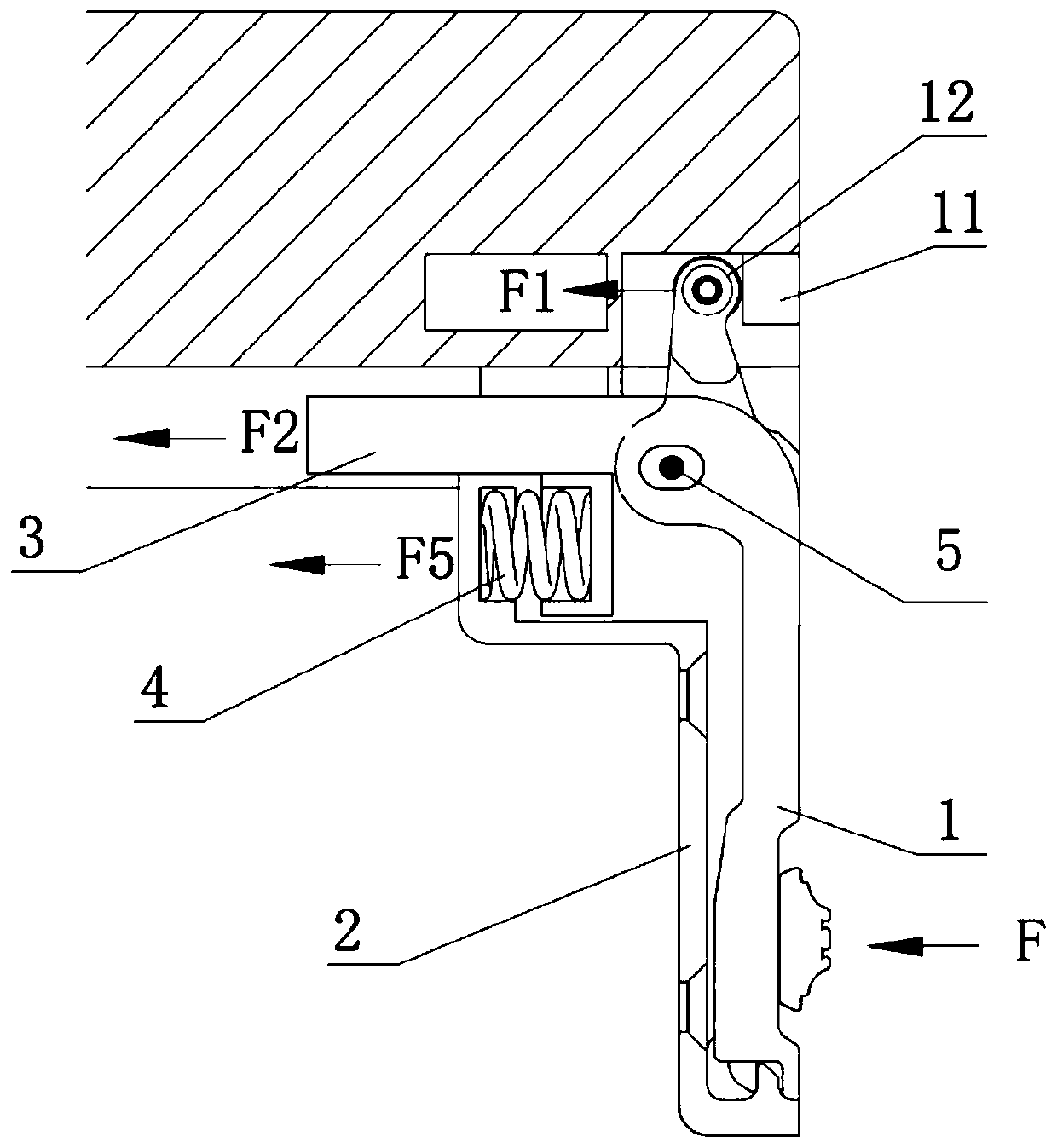

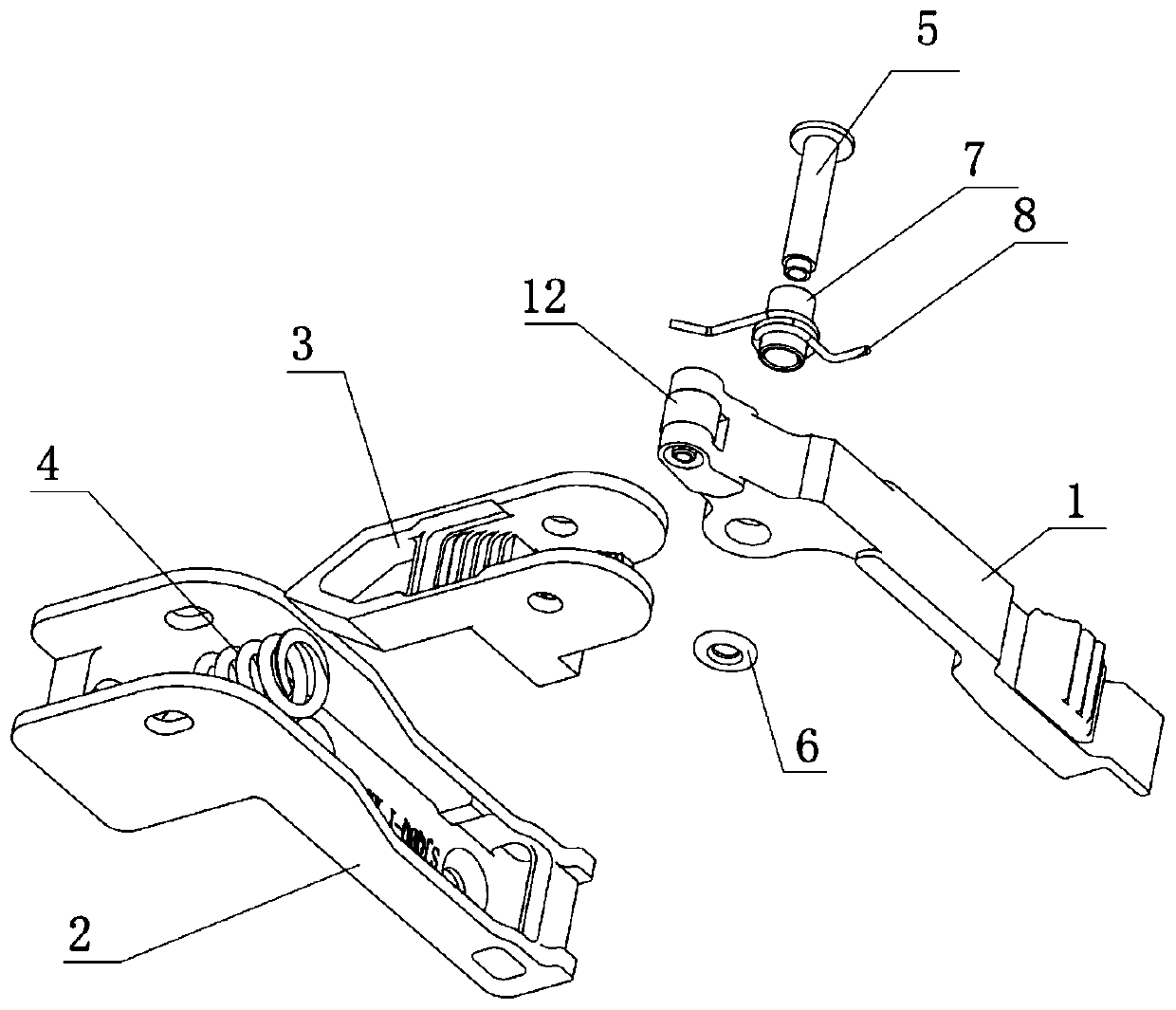

[0014] refer to Figure 1-Figure 4 . In the embodiment described below, an airborne electronic module plug-in locking puller includes: a lifting rod 1 with a horizontal fork elbow, a support 2 with a right-angle elbow, and a fork Wedge block 3 of ear spring groove. The shaft sleeve 7 with the torsion spring 8 passed through the fork eye hole on the horizontal lug elbow of the puller 1, and the wedge block 3 is hinged together by the rotating shaft 5 and the washer 6 inserted into the sleeve 7, and the puller 1. It is close to the seat body of the support 2 in the vertical direction, and the lock on the free end is locked on the locking hook at the bottom of the support 2; into the fork ear spring groove on the top of wedge block 3, and the wedge-shaped conical surface on the top of wedge block 3 protrudes through the opening on the fork ear spring groove to form a moving pair linked by lever 1; The rotation forms the rotating pair and the moving pair controlled by the torsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com