Main-sub type airborne fire extinguishing bomb

A fire-extinguishing bomb and sub-mother technology, which is applied in the field of fire-extinguishing bombs, can solve the problems of difficulty in ensuring the effect of fire-extinguishing agents, low fire-extinguishing efficiency of fire-extinguishing bombs, etc., and achieve the effects of improving load capacity and endurance time, light weight and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

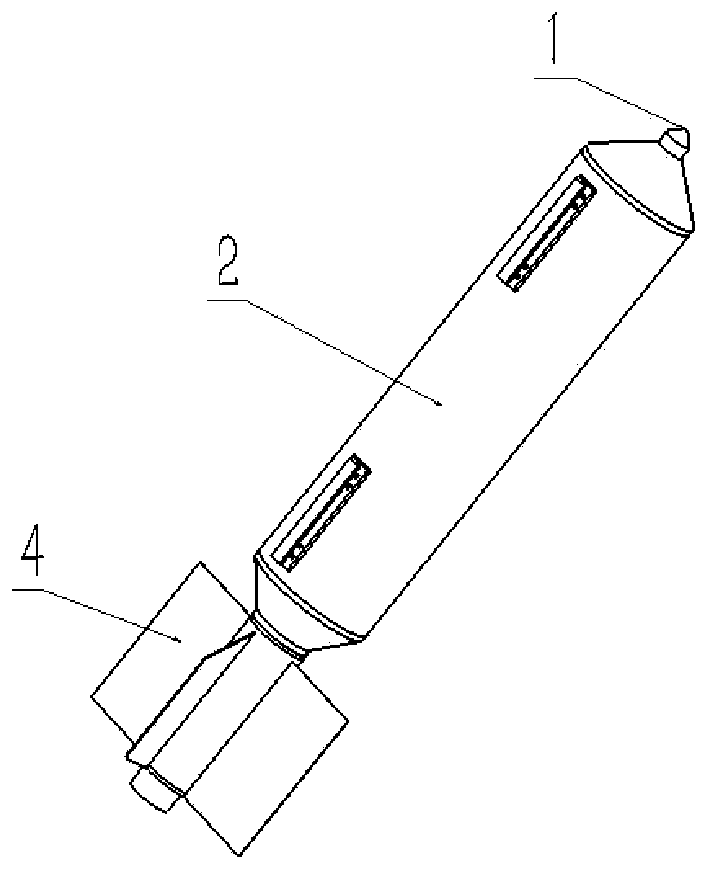

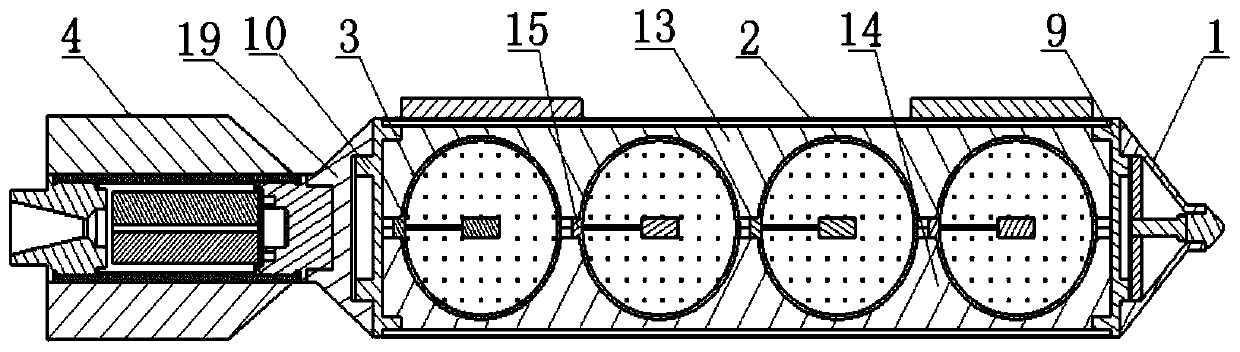

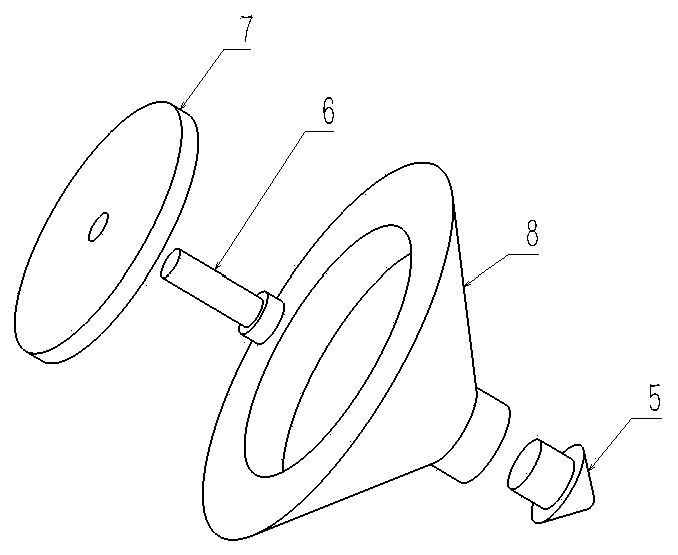

[0041]The present embodiment is an airborne fire extinguishing bomb, comprising a broken window assembly 1, a main bomb body 2 of the fire extinguishing bomb, a sub-fire extinguishing bomb 3, a miniature rocket engine 4, an upper half hatch 13 and a lower half hatch 14 of the sub-fire extinguishing bomb, Wherein: the broken window assembly 1 is installed on the end face of the fire extinguishing bomb main body 2 front end by the front connection cover 9, the rear end end face of the fire extinguishing bomb main body is equipped with a rear connection cover 10, and the front joint 20 of the miniature rocket motor 4 is installed on In the installation hole on the outer end surface of the rear connection cover. The upper half hatch 13 and the lower half hatch 14 of the sub-fire extinguishing bomb are respectively located in the main bomb body 2 of the fire extinguishing bomb, and the upper half hatch and the lower half hatch are fastened to form a sub-fire extinguishing bomb loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com