Road and bridge dotting design for municipal construction

A road and municipal technology, applied in the field of dotting design of roads and bridges for municipal construction, can solve problems such as cleaning of areas that cannot be dotted, uncontrollable dot ink consumption, etc., and achieve the effect of long dot work time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

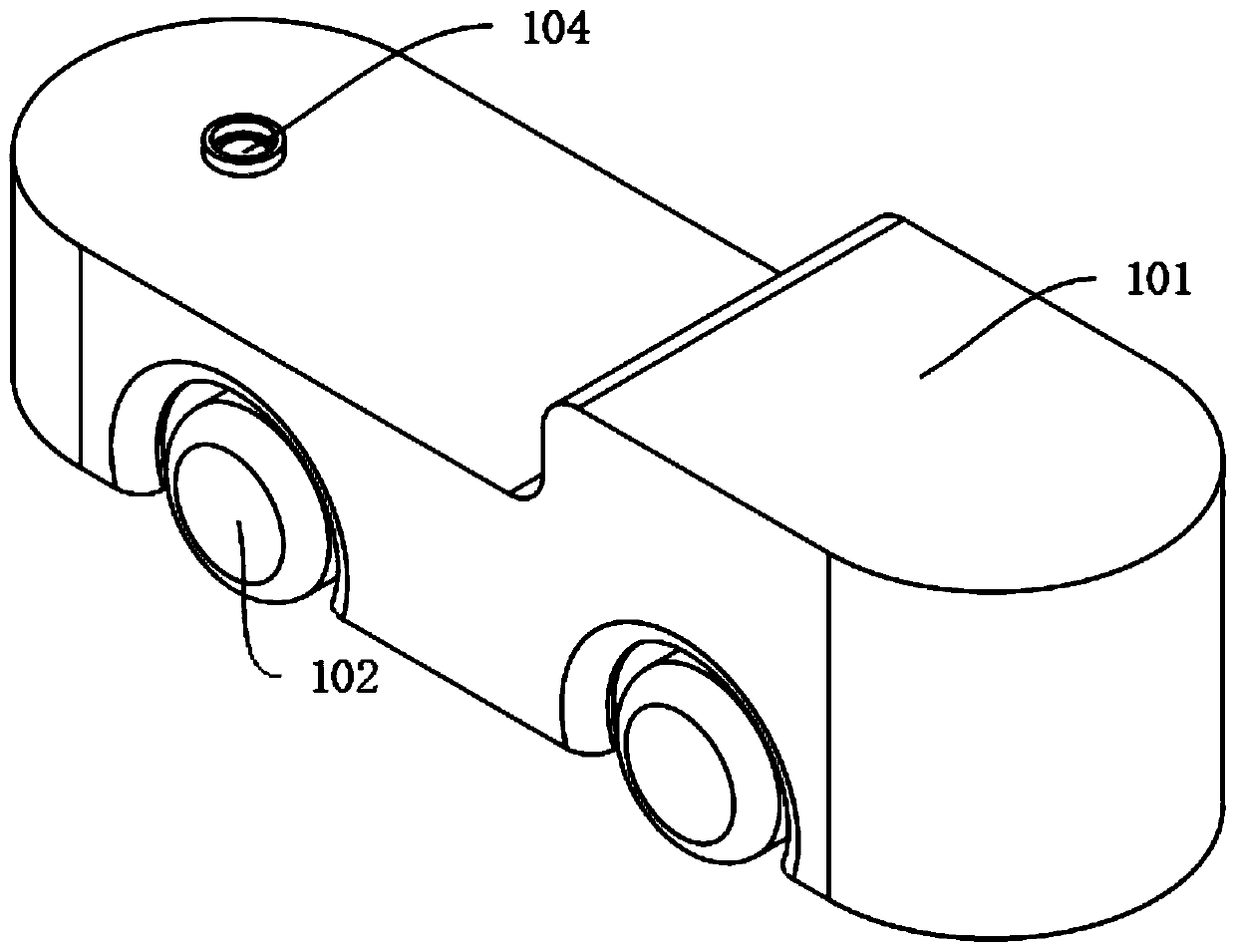

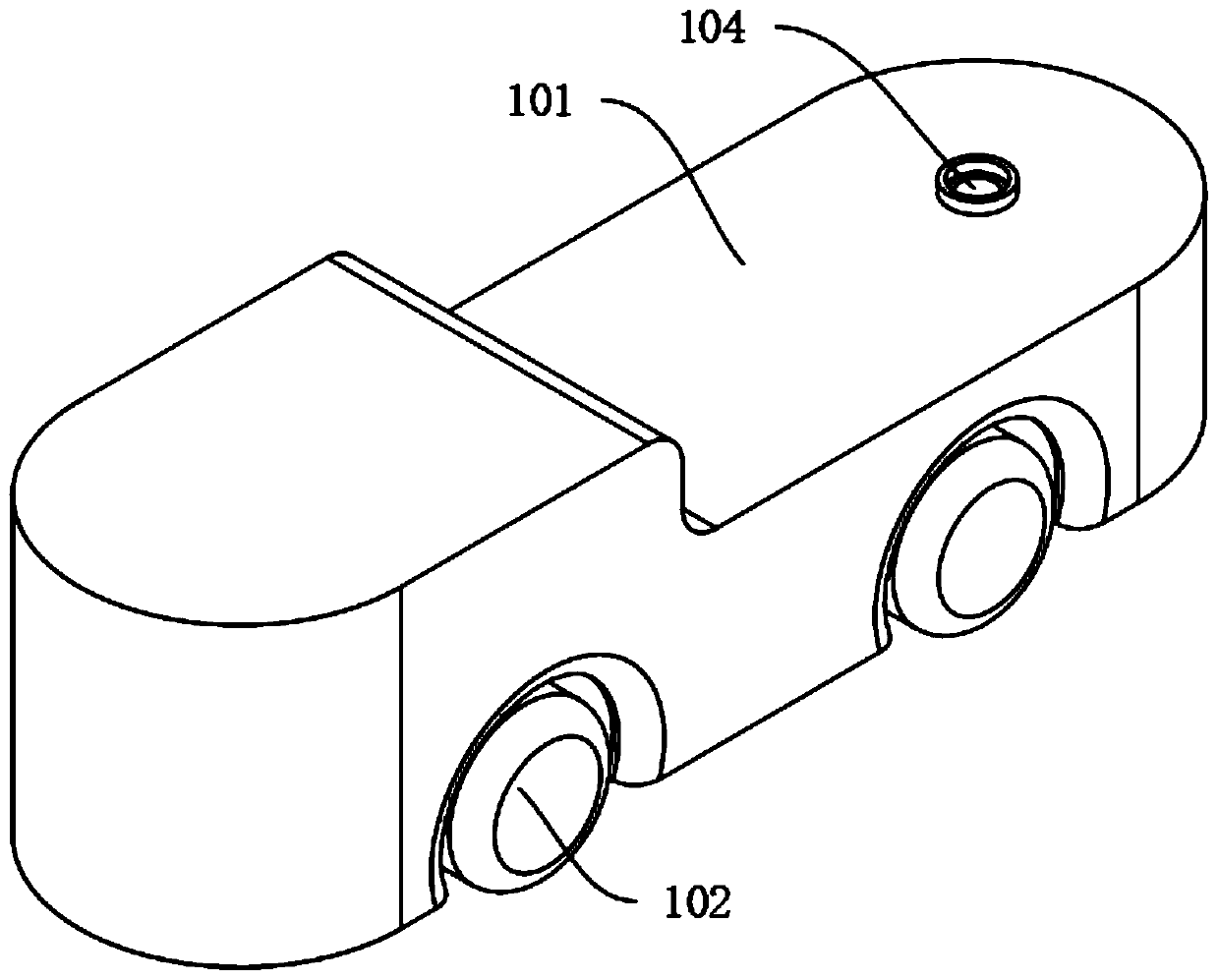

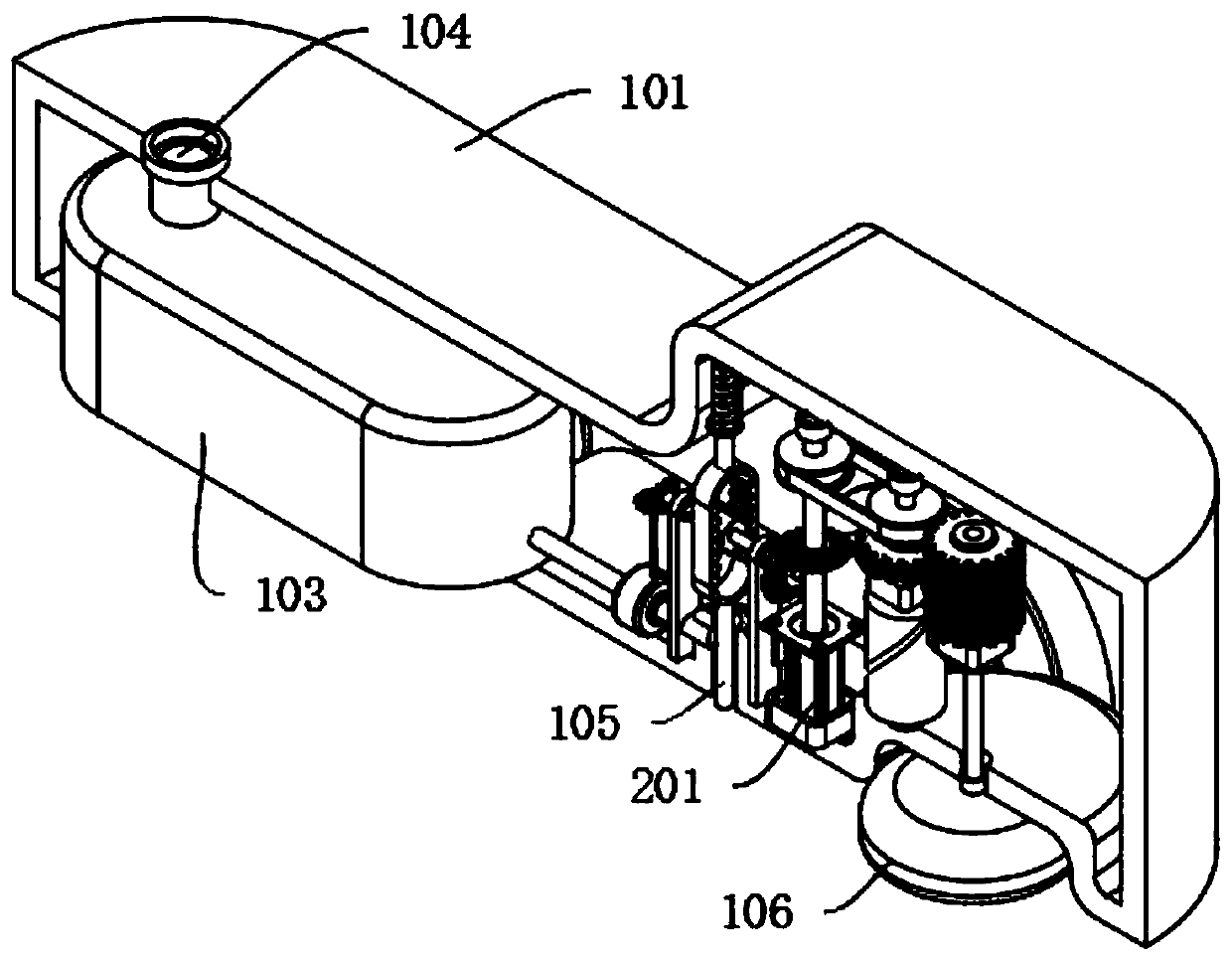

[0030] A kind of road bridge dotting design for municipal construction, comprising: a main body casing 101, a driving device 102 and an ink storage bin 103, the driving device 102 is fixedly installed on the outside of the main body casing 101, and an ink storage bin 103 is fixedly installed on the rear side of the main body casing 101, and the main body casing 101 rear The upper surface is provided with a feeding port 104, the lower end of the feeding port 104 is fixedly connected with the upper surface of the ink storage bin 103 rear side through a pipeline, the front side of the ink storage bin 103 is fixedly connected with the opening and closing mechanism through a pipeline, and the front side of the opening and closing mechanism is connected with the dotting pen 105 through a pipeline. The lower side is movably connected, the upper side of the dotting pen 105 is fixedly connected with the dotting mechanism, the front side of the dotting mechanism is meshed and connected wi...

Embodiment 2

[0032] Embodiment 2: the difference based on Embodiment 1 is;

[0033]The driving mechanism includes: a servo motor 201, a rotating gear 202 and a rotating wheel group 203, the middle part of the main shaft of the servo motor 201 is fixedly connected with the axis center of the rotating gear 202, the upper end of the main shaft of the servo motor 201 is fixedly connected with the rear side of the rotating wheel group 203, and the rotating wheel group 203 The front axle center is fixedly connected with the upper end of the cleaning mechanism, and the lower side of the rotating gear 202 is meshed and connected with the dotting mechanism.

[0034] The cleaning mechanism comprises: a fixed shaft 501, a fixed gear 502, a moving drum 503, a rotating drum 504, a linkage shaft 505 and a moving block 506. The shaft center of the fixed gear 502 is fixedly connected, the lower side of the fixed shaft 501 is fixedly connected with the shaft center of the moving drum 503, the lower end of ...

Embodiment 3

[0036] Embodiment 3: the difference based on embodiment 1 and 2 is;

[0037] The opening and closing mechanism includes: a threaded rotating gear ring 401, a moving block 402, a protective arc block 403, a limiting helical gear 404 and an opening and closing housing 405, and the lower end of the transmission shaft 309 runs through the opening and closing fixed housing 405 and the axial center of the limiting helical gear 404 Fixed connection, the front side of the limiting helical gear 404 is meshed with the upper side and rear of the threaded rotating gear ring 401, and the front and rear sides of the threaded rotating gear ring 401 are the threaded ring and the meshing gear ring respectively, and the front side of the threaded rotating gear ring 401 is evenly distributed in a ring There are three moving blocks 402, and the moving blocks 402 are threadedly connected with the threaded rotating gear ring 401, and the inner end of the moving blocks 402 is fixedly equipped with a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap