A pond duckweed scraper

A duckweed and pond technology, applied in the field of pond duckweed scraper, can solve the problems of danger and labor, and achieve the effect of convenient salvage and concentrated duckweed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

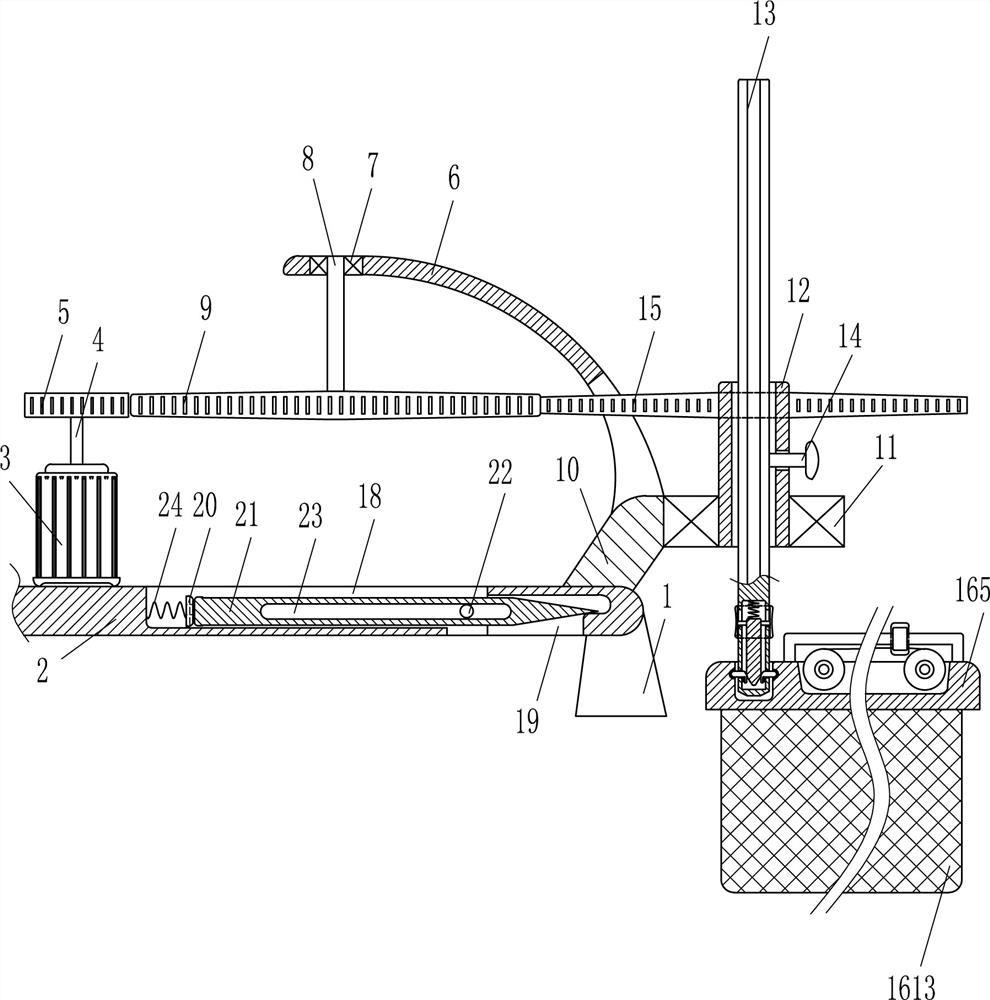

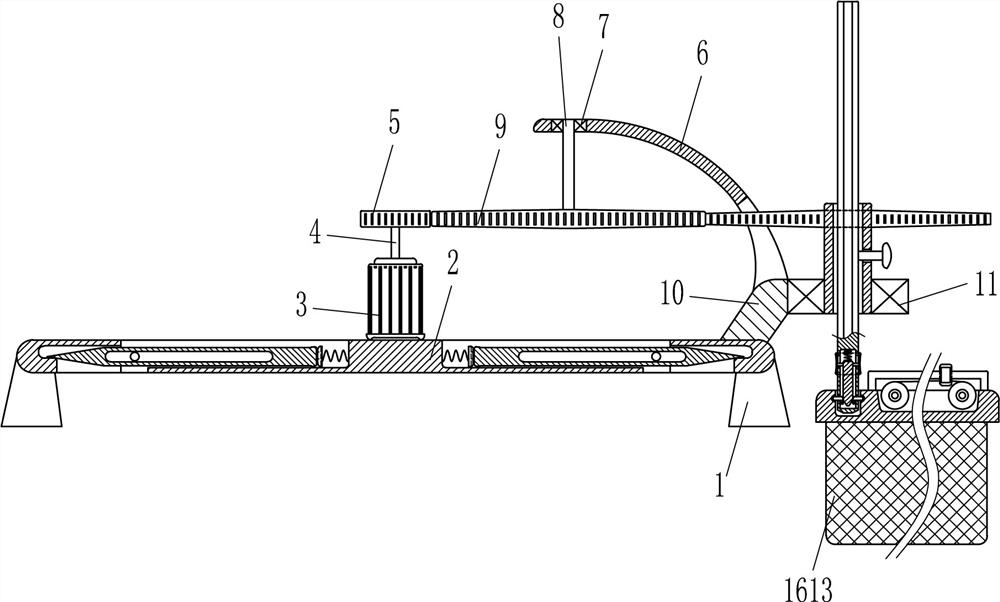

[0016] A pond duckweed scraper, such as Figure 1-3 As shown, it includes a leg 1, a first horizontal plate 2, a servo motor 3, a first shaft 4, a pinion 5, a mounting frame 6, a first bearing seat 7, a second shaft 8, a large gear 9, and a mounting block 10 , the second bearing seat 11, the hexagonal hole rod 12, the hexagonal rod 13, the fastening bolt 14, the middle gear 15 and the pushing device 16, the left and right ends of the first horizontal plate 2 are provided with supporting legs 1, and the first horizontal plate 2 is connected with the outrigger 1 through bolt connection, and the servo motor 3 is arranged in the middle of the top of the first horizontal plate 2, and the first horizontal plate 2 is connected with the servo motor 3 through bolt connection, and the output shaft of the servo motor 3 is provided with The first rotating shaft 4, the top of the first rotating shaft 4 is provided with a pinion 5, the right side of the top of the first horizontal plate 2 i...

Embodiment 2

[0018] A pond duckweed scraper, such as Figure 1-3 As shown, it includes a leg 1, a first horizontal plate 2, a servo motor 3, a first shaft 4, a pinion 5, a mounting frame 6, a first bearing seat 7, a second shaft 8, a large gear 9, and a mounting block 10 , the second bearing seat 11, the hexagonal hole rod 12, the hexagonal rod 13, the fastening bolt 14, the middle gear 15 and the pushing device 16, the left and right ends of the first horizontal plate 2 are provided with supporting legs 1, and the first horizontal plate 2 There is a servo motor 3 in the middle of the top, the output shaft of the servo motor 3 is provided with a first rotating shaft 4, the top of the first rotating shaft 4 is provided with a pinion 5, and the right side of the top of the first horizontal plate 2 is provided with a mounting block 10, the mounting block 10 The top is provided with a mounting frame 6, the left part of the mounting frame 6 is provided with a first bearing seat 7, the first bea...

Embodiment 3

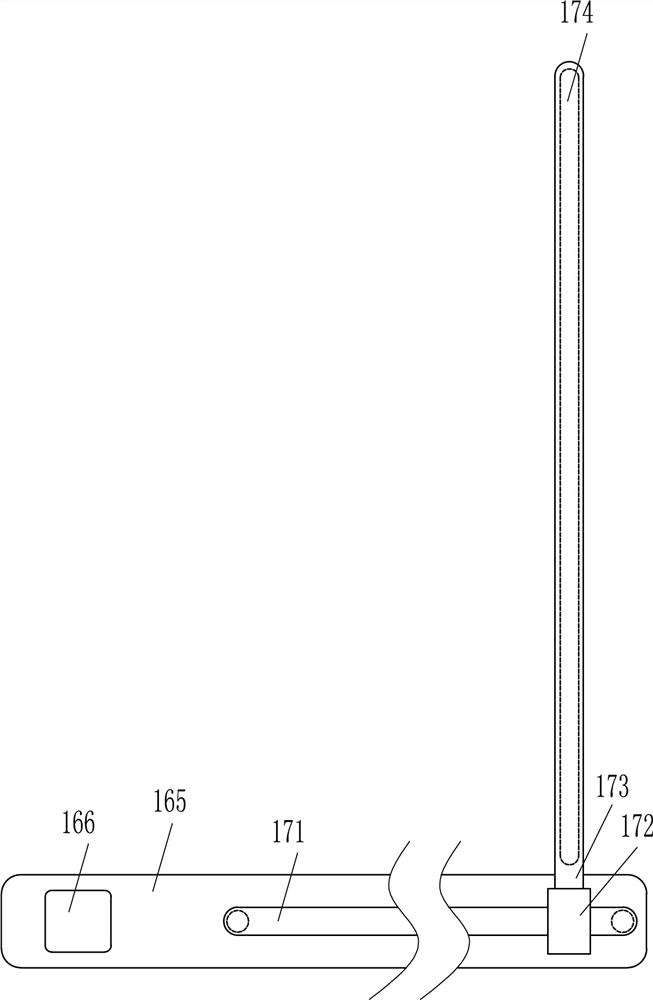

[0021] A pond duckweed scraper, such as Figure 1-4 As shown, it includes a leg 1, a first horizontal plate 2, a servo motor 3, a first shaft 4, a pinion 5, a mounting frame 6, a first bearing seat 7, a second shaft 8, a large gear 9, and a mounting block 10 , the second bearing seat 11, the hexagonal hole rod 12, the hexagonal rod 13, the fastening bolt 14, the middle gear 15 and the pushing device 16, the left and right ends of the first horizontal plate 2 are provided with supporting legs 1, and the first horizontal plate 2 There is a servo motor 3 in the middle of the top, the output shaft of the servo motor 3 is provided with a first rotating shaft 4, the top of the first rotating shaft 4 is provided with a pinion 5, and the right side of the top of the first horizontal plate 2 is provided with a mounting block 10, the mounting block 10 The top is provided with a mounting frame 6, the left part of the mounting frame 6 is provided with a first bearing seat 7, the first bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com