Laminator silica gel plate conveying device

A technology of conveying device and silica gel plate, which is applied in the direction of conveyor objects, transportation and packaging, photovoltaic power generation, etc., can solve the problems of waste time and labor of silica gel plate, and achieve the effect of convenient operation, convenient lifting, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

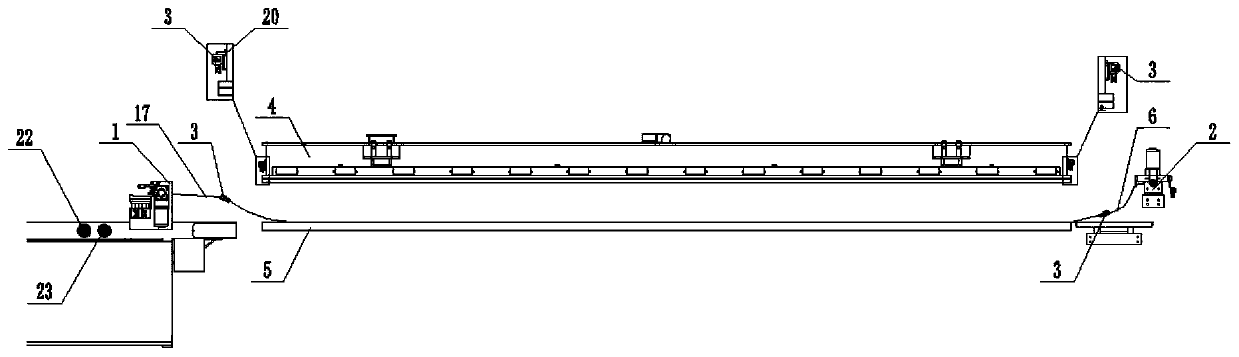

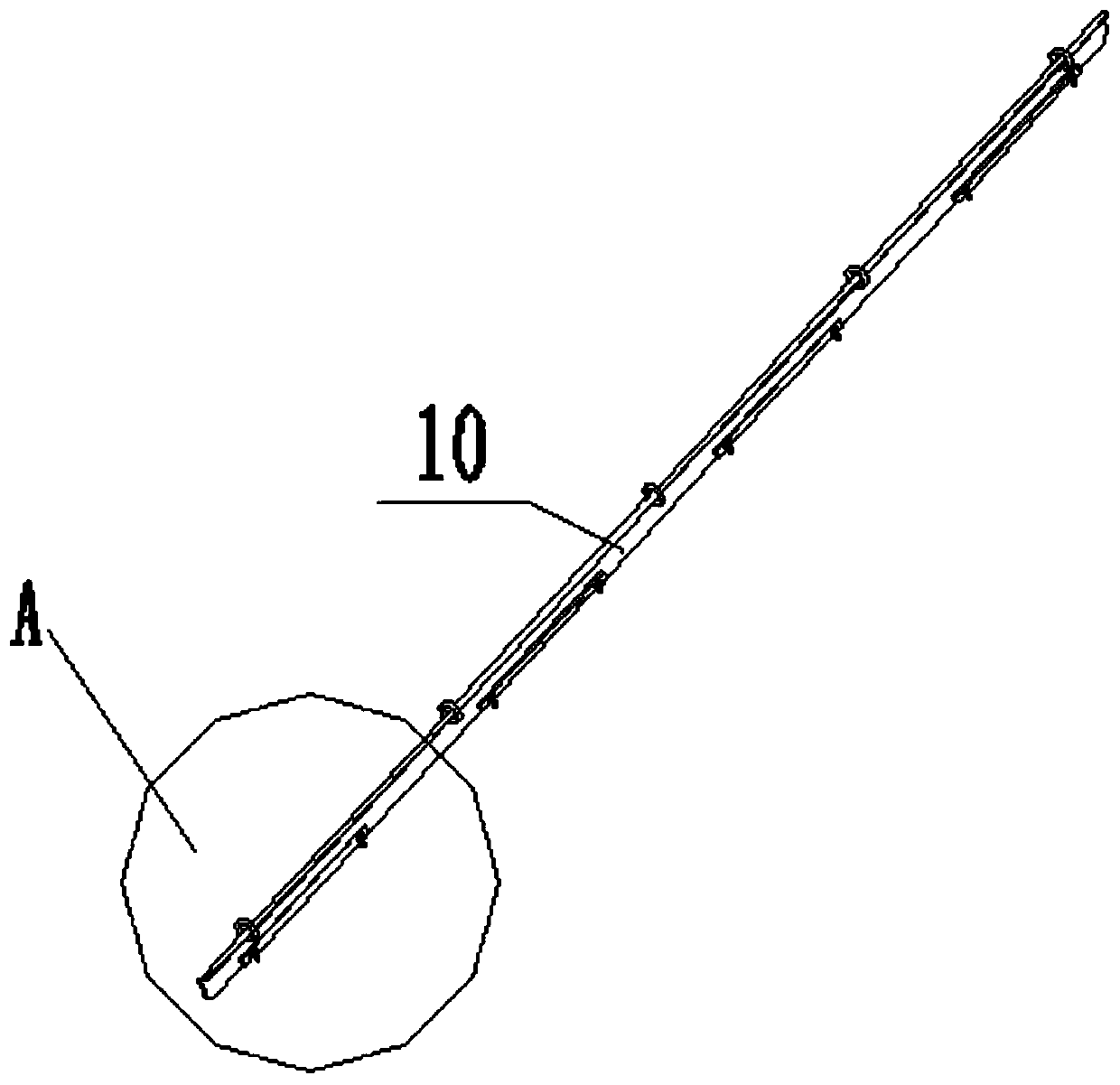

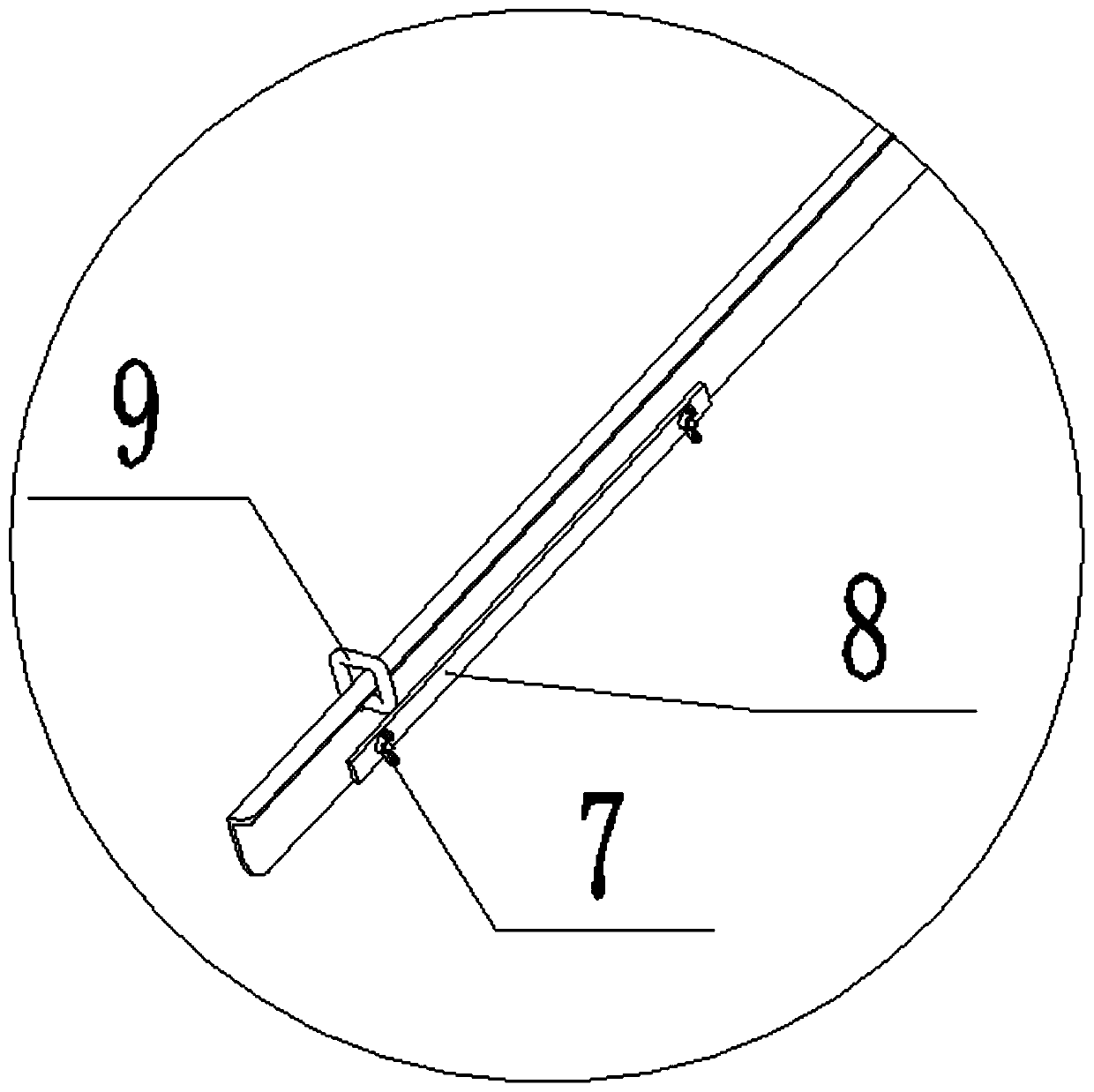

[0021] see Figure 1-4 , a silicone plate conveying device for a laminator, comprising: a waste silicone plate retracting device 1, a new silicone plate pulling device 2, a silicone plate clamping rod 3, a work surface 5 and an upper box 4, and the work surface 5 is arranged on the upper box 4, the two ends of the upper box 4 are provided with silicone plate transverse tie rods 20, and a lamination chamber is formed between the upper box 4 and the work surface 5. The silica gel plate 6 is placed on the worktable 5, and the waste silica gel plate retracting device 1 and the new silica gel plate pulling device 2 are respectively arranged on both sides of the upper box 4. The silica gel plate clamping rod 3 is detachably connected with the waste silica gel plate retracting device 1 and the new silica gel plate pulling device 2 through a steel wire rope 17. The silicone plate clamping rod 3 includes a rotating screw 7 , a pressing plate 8 , a lifting ring 9 and a clamping rod bod...

Embodiment 2

[0025] see Figure 5 , On the basis of Embodiment 1, the new silica gel plate pulling device 2 includes a second drive motor 24, a wire rope winding roller 25, a wire rope guide rod 26, an electromagnetic coupling 27, a seated bearing 28, a bearing mounting plate 29, Mechanism mounting base 30, the mechanism mounting base 30 is installed on the main frame body through bolt connection, the top of the mechanism mounting base 30 is fixed with a bearing mounting plate 29 by bolts, and the two ends of the wire rope winding roller 25 are rotatably connected through the belt seat bearing 28 On the bearing mounting plate 29, the second driving motor 24 is installed on the mechanism mounting seat 30 by bolts, and the electromagnetic coupling 27 is installed in the middle of the wire rope winding drum 25 and the second driving motor 24 through a flat key, for transmitting the second driving motor. Drive the torque of the motor 24, the wire rope guide rod 26 is installed on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com