Recovery type thick reinforcing bar anchor rod and recovery method

A technology of steel bars and anchors, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of low anchor bearing capacity, difficult recovery, low precision, etc., to improve the anchor bearing capacity, quick and easy recovery, The effect of saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

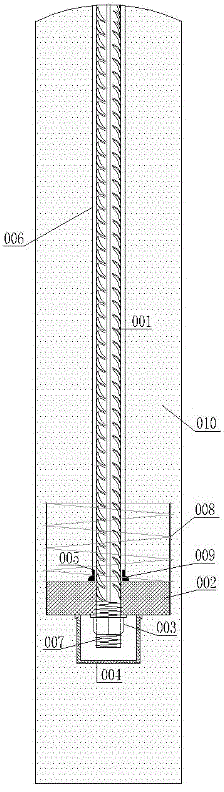

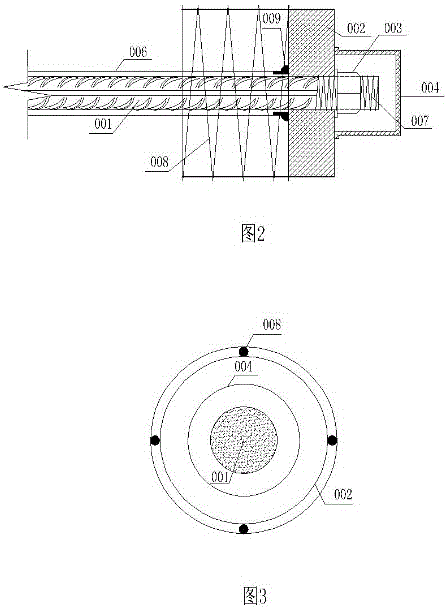

[0018] One end of the thick steel bar body (001) is processed with a steel bar outer thread head (007), and the device set up to prevent the slurry from wrapping the recovery device nut (003) and the steel bar outer thread head (007) during the grouting process is called end protection. The bin (004), the fixing device for fixing the PVC casing (006) is called the PVC casing positioning ring (005), and the device for preventing the grouting body (010) from leaking into the PVC casing during the grouting process is called the anti The leakage isolation layer (009), the recovery device that is welded to the pressure bearing plate (002) and connected to the steel bar body (001) is called the recovery device nut (003), and is connected with the end bearing plate as a whole to jointly bear the force The device is called End Bearing Stiffener (008).

[0019] Such as figure 1 , figure 2 As shown, the recovery device nut (003) is welded to the pressure plate (002), and the grade ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com