Temporary bracket arranged by utilizing steel casings and construction method thereof

A steel casing and bracket technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of pile body structure stress and appearance quality are greatly affected, installation and removal are difficult, and construction technology is complicated. Achieve the effect of shortening the construction period, simple construction method and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

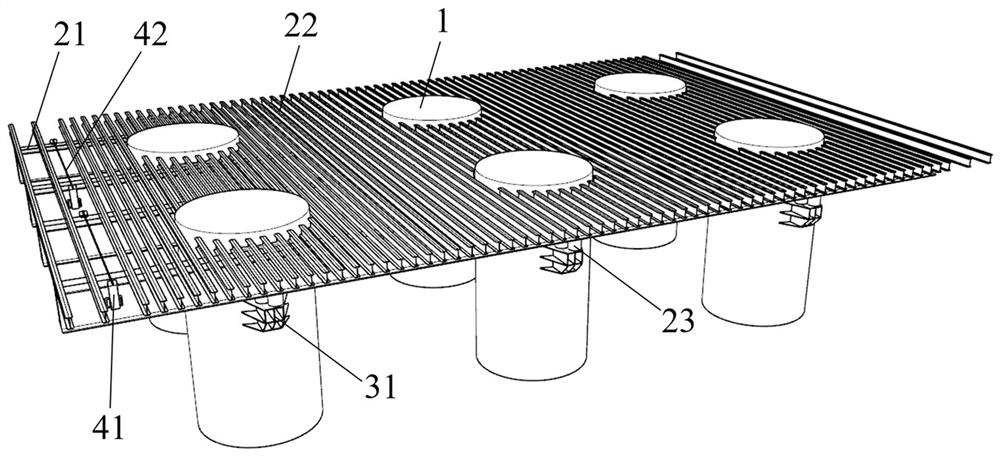

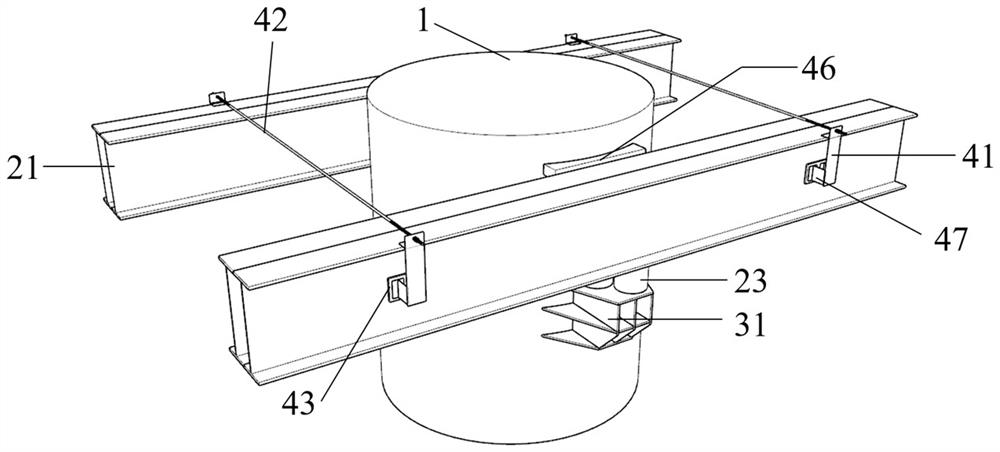

[0045] See figure 1 and figure 2 , a temporary bracket arranged using steel casings, including steel casings 1 arranged in a matrix, each row of the matrix includes more than two steel casings 1, and each column of the matrix includes more than two steel casings 1 ;

[0046] Both sides of each row of steel casings are horizontally supported by a corbel mechanism and arranged with transverse beams 21, and two adjacent transverse beams 21 are clamped and arranged on both sides of each row of steel casings by a clamping mechanism;

[0047] Longitudinal beams 22 are evenly arranged on the upper ends of the transverse beams 21;

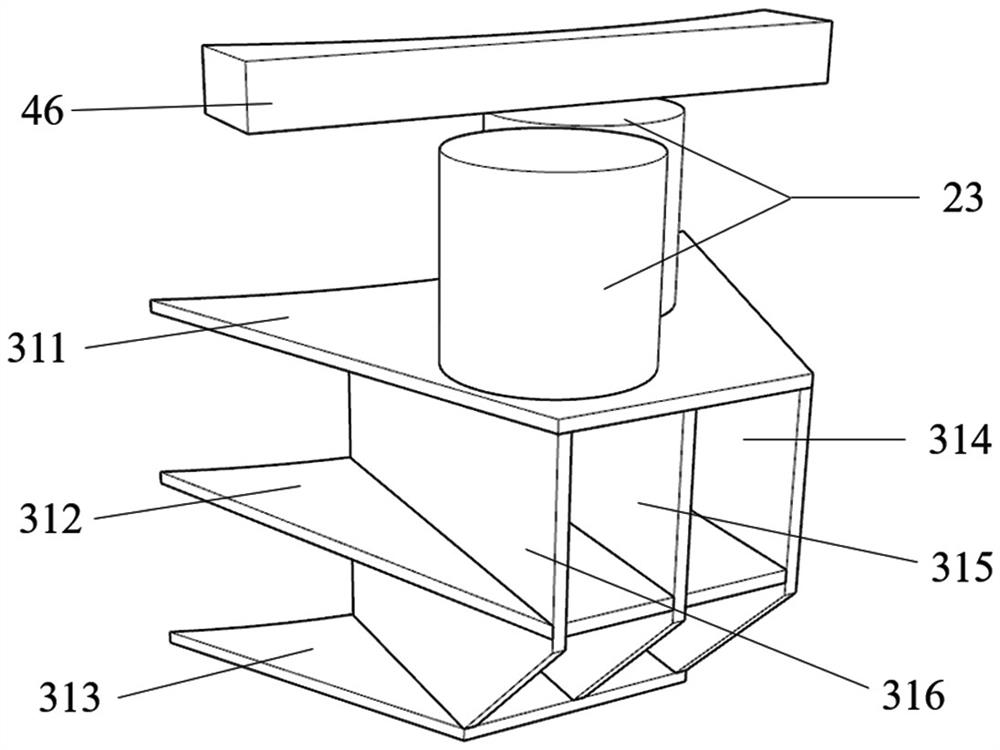

[0048] Each of the corbel mechanisms includes more than two corbels 31, and the opposite sides of each steel casing 1 are correspondingly fixedly installed with the corbels 31, and the upper end of each corbel 31 is vertically arranged to support the corresponding transverse beam. 21 more than two unloading sand barrels 23;

[0049] The clamping mecha...

Embodiment 2

[0064] The construction method of embodiment 1 temporary bracket, comprises the following steps:

[0065] Step 1: Remove the mud on the inner and outer walls of the steel casing 1 within the scope of the corbel 31, derust the wall within the scope of the steel casing 1, and weld the first layer of partitions 311 and the third layer of partitions 313 of the corbel 31 The elevation line is released and marked on the steel casing 1;

[0066] Step 2: After the corbel 31 is processed and formed by the steel structure processing plant, it is transported to the construction site, and the corbel 31 is lifted to the marked position by a crane, and welded and fixed on both sides of the steel casing 1;

[0067] Step 3: Fill the sand removal cylinder 23 with dry coarse sand, pour C30 concrete in the cylinder core, and perform preloading; after the preloading is completed, fix the sand removal cylinder 23 and the first layer of partitions 311 by spot welding, When multiple sand dumping tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com