Beam reinforcing suspended formwork device and construction method thereof

A technology of beam reinforcement and formwork hanging, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building maintenance, etc. It can solve the problems of reduced strength, uneconomical, and inability to support formwork, etc. problems, to achieve the effect of low assembly cost, convenient construction, and reduced construction work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In one embodiment, the preparation method of the anti-sticking coating comprises the following steps: taking epoxy acrylic resin, epoxy resin, polyvinylidene fluoride, acrylate monomer, perfluorononoxybenzene sulfonic acid Sodium, modified nano-zinc oxide, photoinitiator, propylene glycol ether and organic solvent, add perfluorononoxybenzene sodium sulfonate, modified nano-zinc oxide, polyvinylidene fluoride to the organic solvent in turn under the stirring condition of 300-800rpm Ethylene, acrylate monomer, epoxy acrylic resin and epoxy resin, after stirring for 30-60 minutes, add photoinitiator and propylene glycol ether, and continue stirring for 10-20 minutes to obtain the anti-adhesive coating.

[0055] In another typical implementation of the present application, a construction method using the above-mentioned beam reinforcement hanging formwork device is provided, including the following steps:

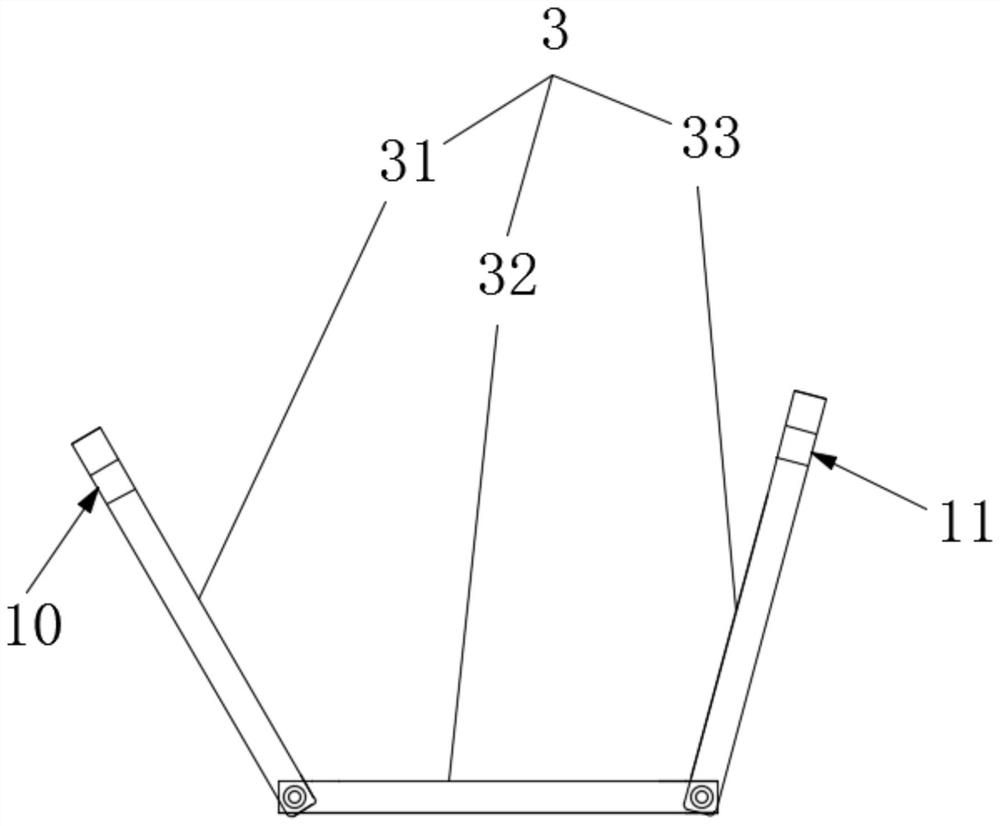

[0056] (S1), first fix the first steel arm 31 or the second steel a...

Embodiment 1

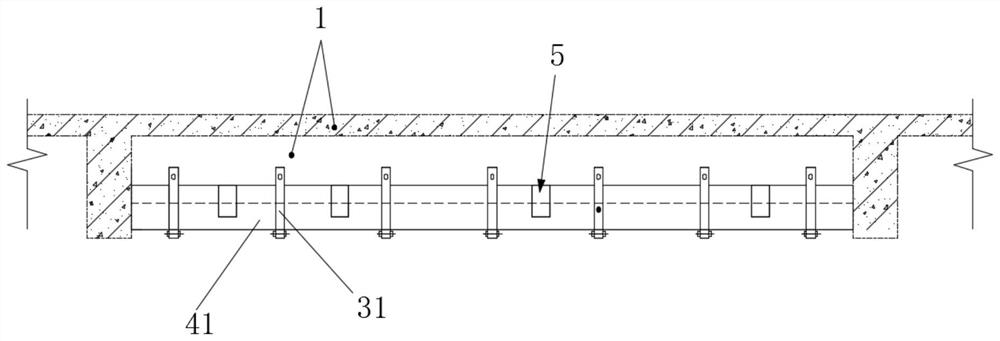

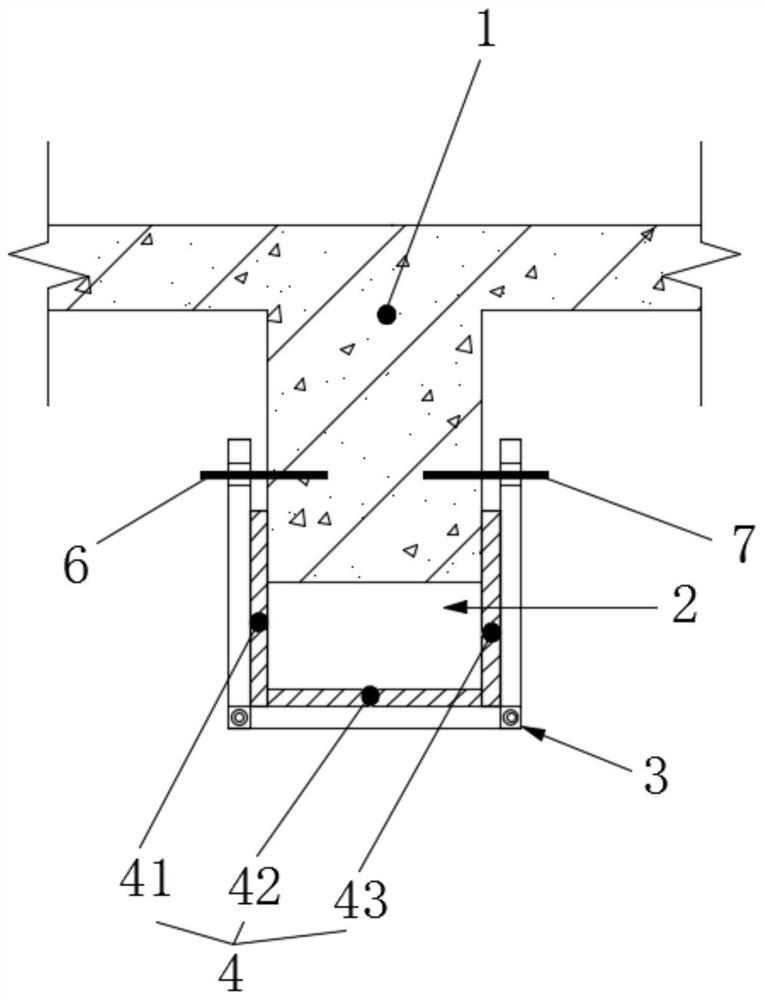

[0061] Such as Figure 1-3 As shown, a beam strengthening formwork hanging device includes a beam body 1, and the beam strengthening formwork hanging device also includes a boom assembly 3 connected to the beam body 1, and a hanger assembly arranged between the beam body 1 and the hanger assembly. 3 between the combined formwork 4, the combined formwork 4 is against the suspender assembly 3, the reinforcement space 2 for accommodating the reinforcement slurry is formed between the beam body 1 and the combined formwork 4, and the suspender The assembly 3 includes a first steel arm 31, a supporting member 32 and a second steel arm 33, one end of the first steel arm 31 and one end of the second steel arm 33 are respectively connected to the two sides of the beam body 1, the The other end of the first steel arm 31 and the other end of the second steel arm 33 are respectively movably connected with the two ends of the supporting member 32 .

[0062] The number of the boom assembli...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is:

[0071] Such as figure 1 , Figure 4-6 As shown, in this embodiment, the beam-reinforced form-hanging device further includes a locking member 8 that cooperates with the supporting member 32, and an adjustment hole 9 is opened at one end of the supporting member 32, and the locking The member 8 passes through the adjustment hole 9 and is connected to the second steel arm 33 , and the first steel arm 31 is hinged to the supporting member 32 .

[0072] In this embodiment, the locking member 8 is a pin, and the adjusting hole 9 is long.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com