Stepping giant magnetostrictive precision rotary drive device

A rotary drive device and ultra-magnetic technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., to achieve stable rotation, flexible operation, and improved load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

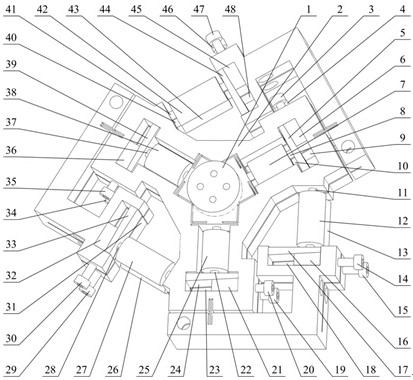

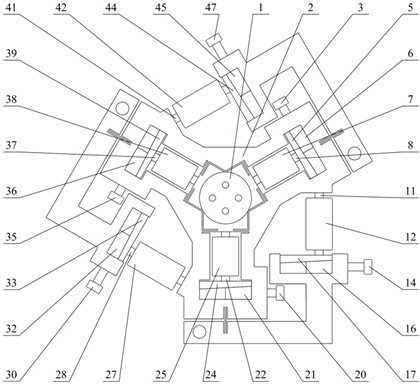

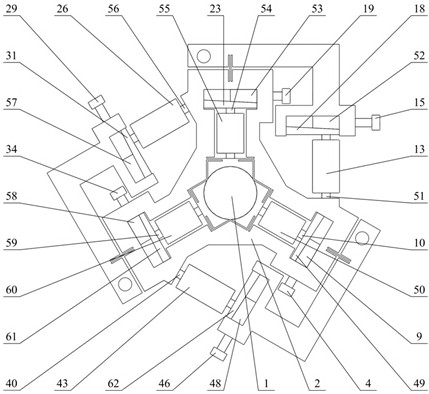

[0034] see Figure 1-12 , a step-by-step giant magneto-induced precision rotary drive device, including a rotor 1, a stator 2, a clamping mechanism, a drive mechanism, a preloading mechanism and a giant magneto-induced multi-pulse signal controller; the middle of the stator 2 is provided with a rotor 1, a clamping mechanism The tightening mechanism is located between the rotor 1 and the stator 2, the inner side of the stator 2 is provided with an installation groove, and the clamping mechanism is installed in the installation groove;

[0035] The stator 2 is divided into upper and lower layers, the stator includes an upper stator layer, a lower stator layer and a base, the upper stator layer and the lower stator layer are respectively connected with the base by three evenly distributed flexible hinges, and the base is fixed on the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com