Filament and method for producing same

A manufacturing method and filament technology, applied in the direction of manufacturing tools, additive manufacturing, single-component polyester artificial filament, etc., can solve the problems of reduced reproduction accuracy, uneven cross-sectional shape, poor transmission effect, etc., to achieve transmission Effects of reduction in failures, reduction in transmission failures, and expansion of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0093] The filament and the manufacturing method of the filament of the present invention will be described in detail based on the first embodiment and examples.

[0094] Filament manufacturing process

[0095] The filaments in this embodiment are produced by a general extrusion molding machine.

[0096] Specifically, a 65φ extruder was used. Cylinder temperature ranges from 150°C to 180°C for the die, 160°C to 200°C for the metering section, 160°C to 200°C for the compression section, and 150°C to 180°C for the supply section.

[0097] In addition, the limit temperature is 240°C, the temperature of the cooling water in the cooling water tank is 8°C to 15°C, the distance between the mold and the classifier is 2cm to 5cm, the take-out rate is 0.87 to 0.92, and the sizing method is drive.

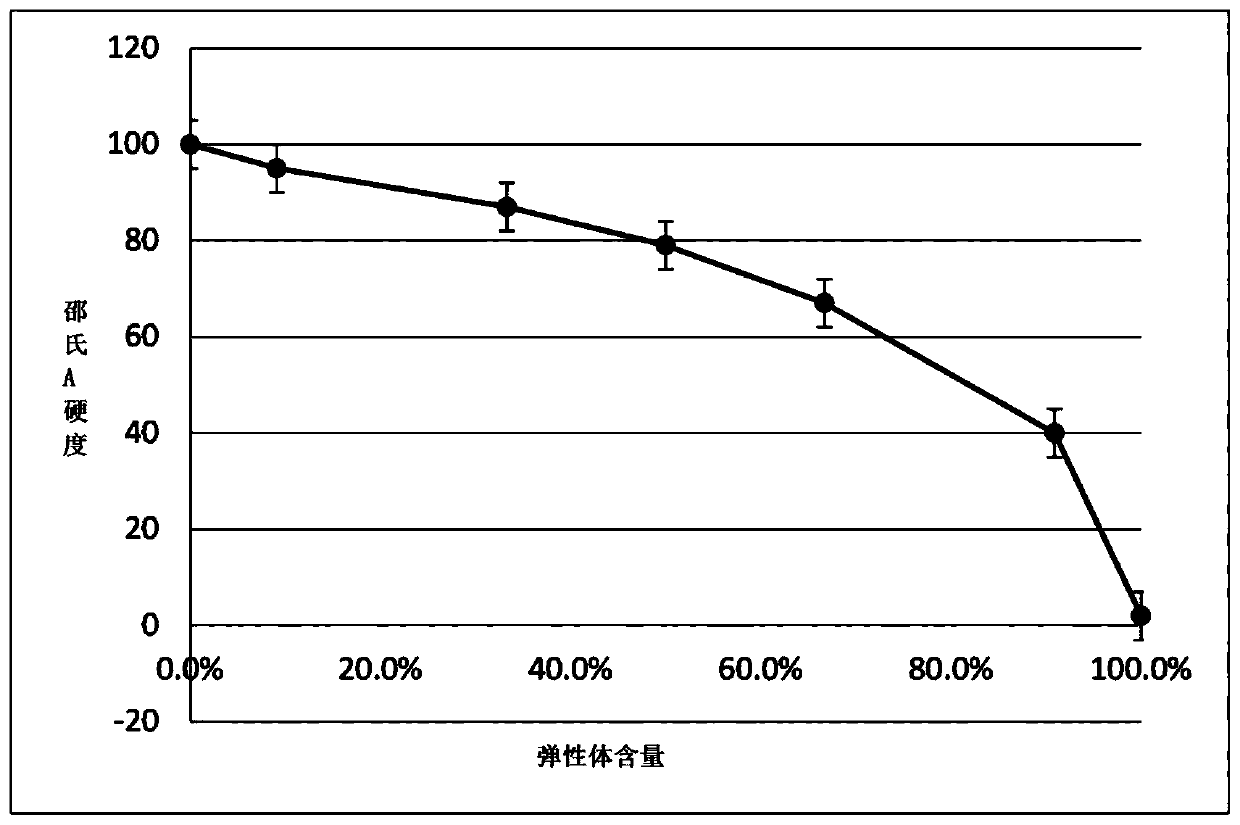

[0098] The filament in this embodiment is after mixing the particles of the polylactic acid resin (A) and the particles of the thermoplastic elastomer (B) with a total weight of 100%, addin...

manufacture example 1

[0118] Production Example 1 Preparation of Filament (1)

[0119] The filament (1) in this embodiment is obtained by mixing the particles of the polylactic acid resin (A) and the particles of the thermoplastic elastomer (B) (the content of the thermoplastic elastomer is 9.1%) in a ratio of 10:1 by weight, and extruding Molded.

manufacture example 2

[0120] Production Example 2 Production of Filament (2)

[0121] The filaments (2) in this embodiment are mixed with particles of polylactic acid resin (A) and particles of thermoplastic elastomer (B) (thermoplastic elastomer content: 33.3%) in a ratio of 2:1 parts by weight, and then extruded Molded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com