Food processor

A cooking machine and body technology, applied in the field of cooking machines, can solve the problems of large body size and large space occupied by locking parts, and achieve the effects of small moving space, avoiding forgetting, and reducing the size of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a cooking machine, which can be used to make various foods such as fruit juice, soybean milk, jam, dry powder, shaved ice, and minced meat.

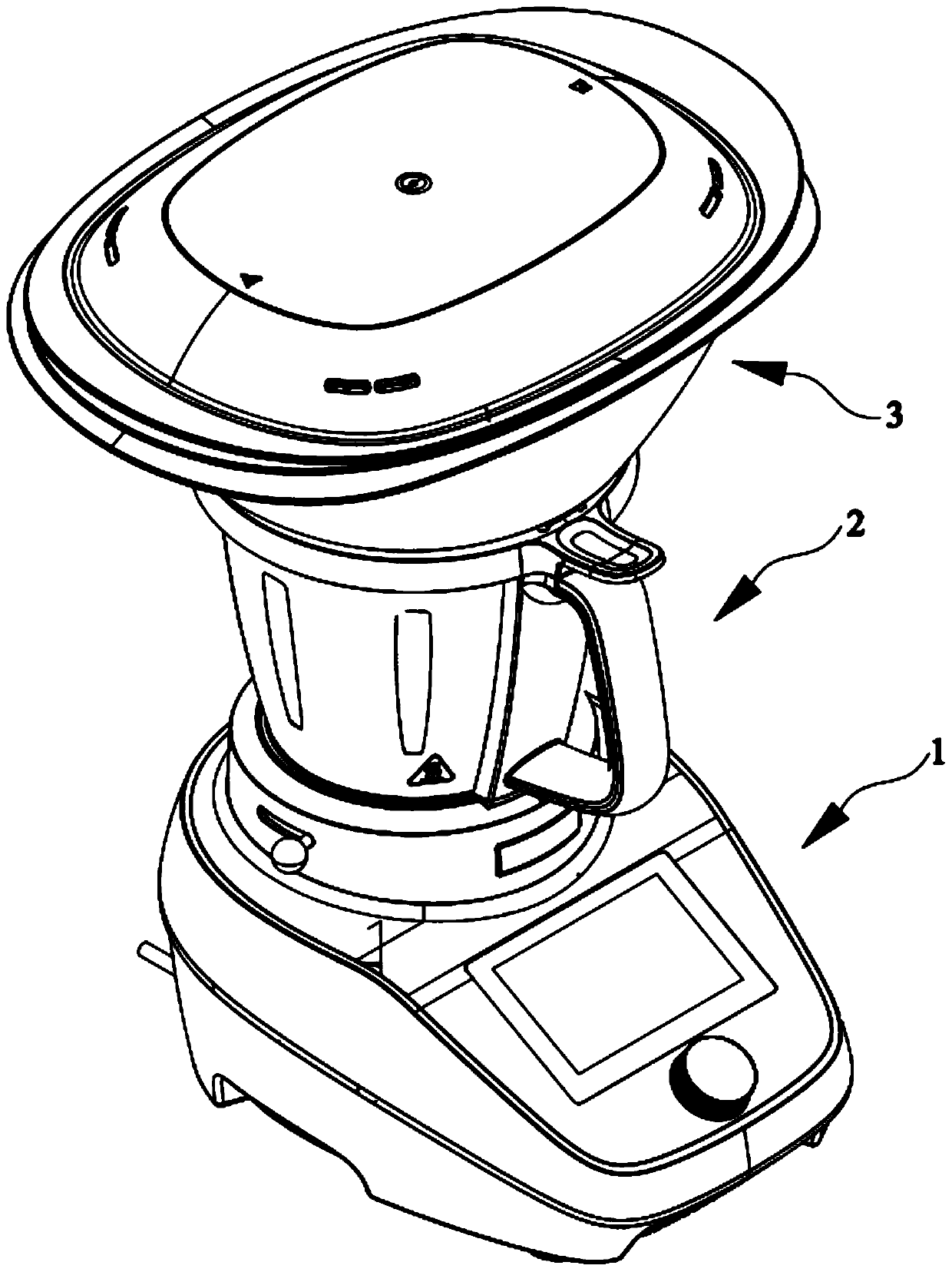

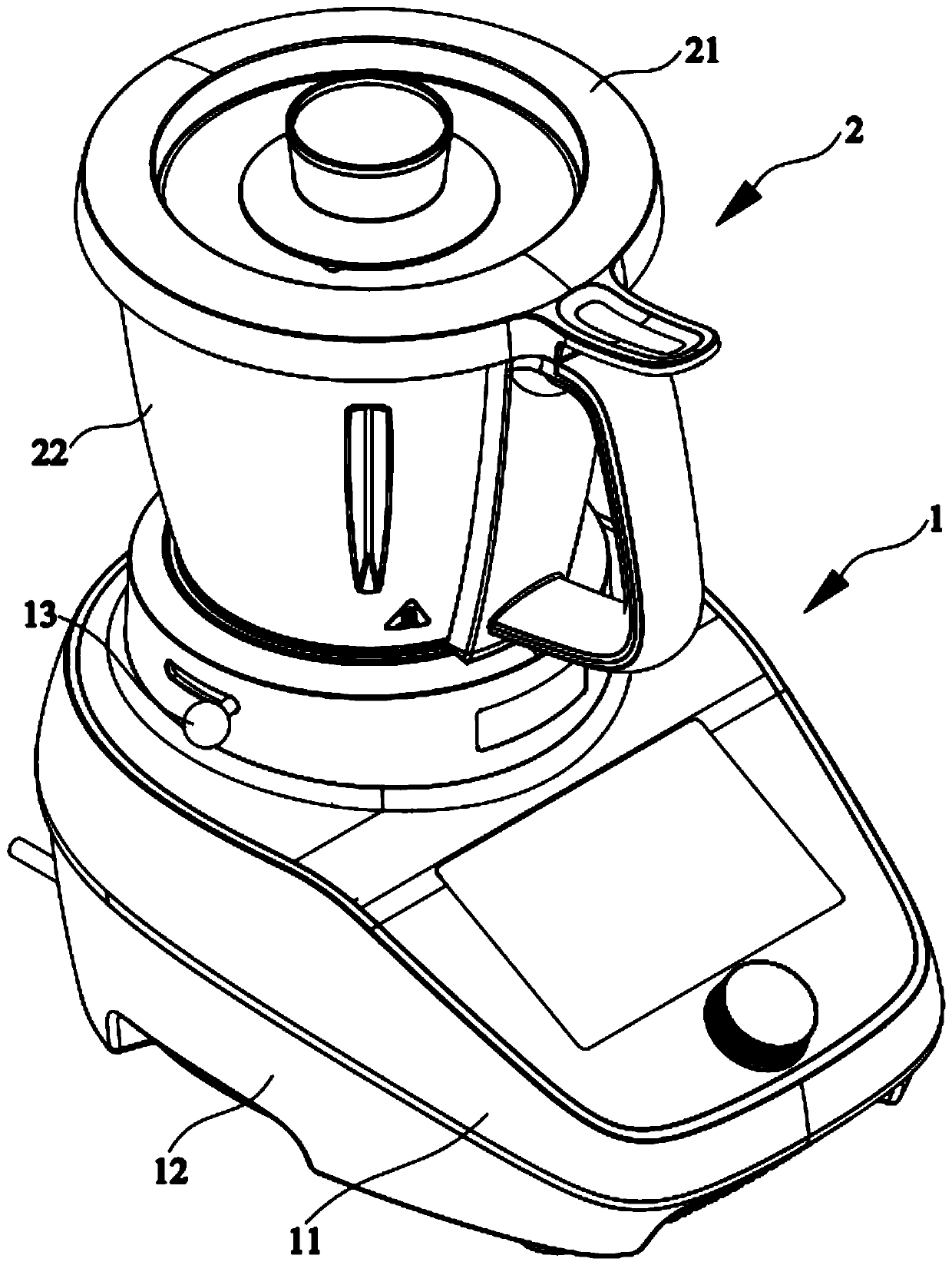

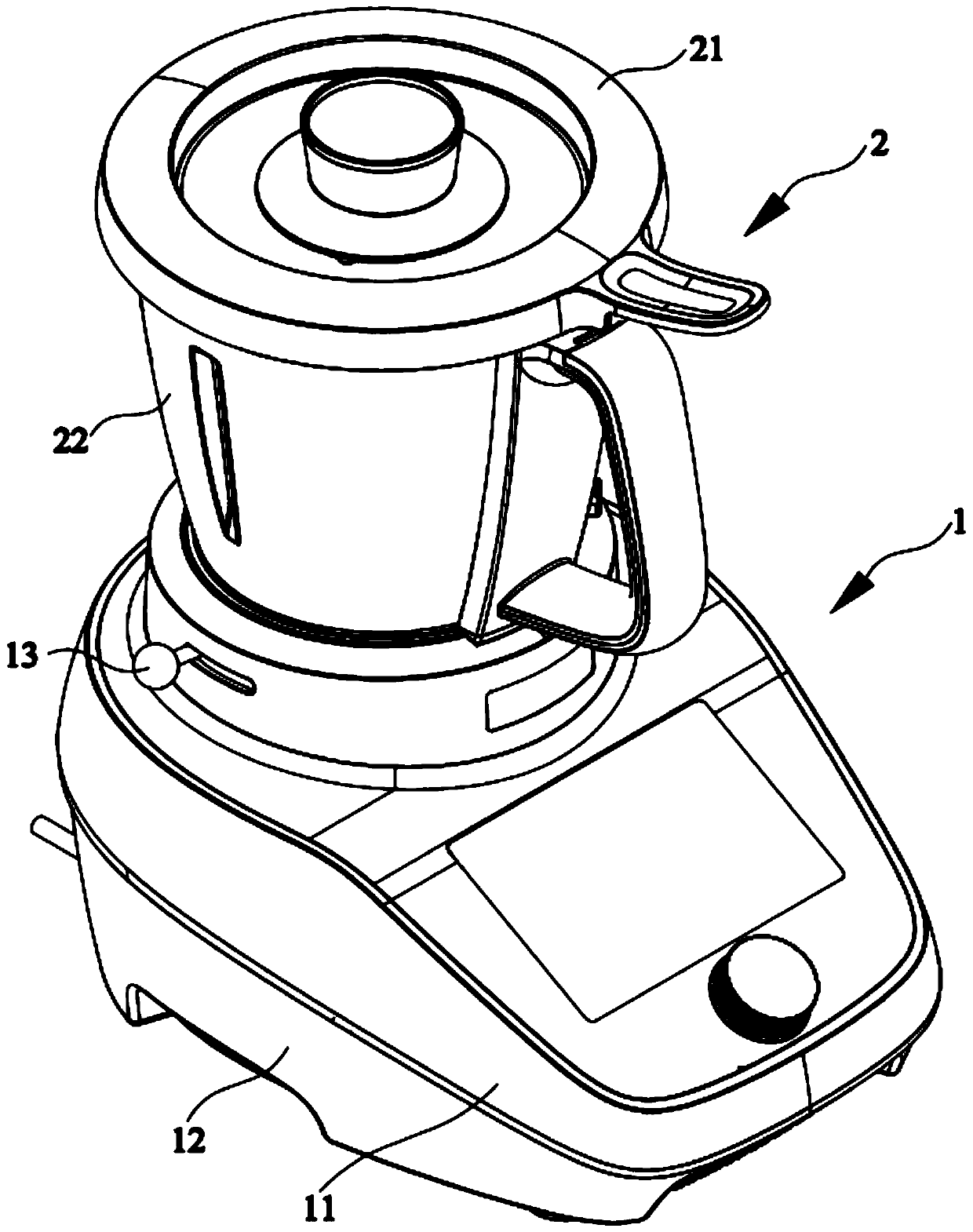

[0090] Such as figure 1 As shown, the cooking machine includes a body 1 , a container assembly 2 and a steamer assembly 3 . The body 1 serves as the carrier of the container assembly 2 and the steamer assembly 3, and contains functional components such as a power system and a control system. The container assembly 2 can be installed on the machine body 1 , and a cutter assembly and a heating assembly are arranged therein. The cutter assembly is used for further processing the food, and the heating assembly is used for heating the inside of the container assembly 2 . It should be noted that the steamer assembly 3 is not necessary as an auxiliary device. The steamer assembly 3 can be detachably connected with the container assembly 2. When the steamer assembly 3 is needed, water is placed in the container a...

Embodiment 2

[0133] This embodiment provides a cooking machine, which is different from Embodiment 1 in that the cooking machine can judge whether the container assembly 2 and the body 1 are locked, and when the container assembly 2 and the body 1 are locked, the cooking machine can be started to ensure The user can only start the cooking machine when the container assembly 2 is locked with the body 1 .

[0134] The cooking machine also includes a trigger mechanism, which can determine whether the container assembly 2 is locked with the body 1 . When the container assembly 2 is normally installed on the body 1, the locking member 4 moves to the locking position to lock the container assembly 2, and at the same time, the locking member 4 at the locking position can trigger the trigger mechanism, so that the container assembly 2 is in the position with the body 1. Information about the state of the lock.

[0135] Specifically, such as Figure 16 with Figure 17 As shown, the trigger mecha...

Embodiment 3

[0151] In order to avoid dangers caused by the incorrect installation of the cutter assembly 8 in the container assembly 2 after the container assembly 2 is placed on the body 1 to work, this embodiment provides a cooking machine, which is different from the above-mentioned embodiment That is, the cooking machine also includes a detection component, which can detect the installation state of the knife assembly 8 and the container assembly 2, so as to avoid the cooking machine from starting when the knife assembly 8 is in an abnormal state.

[0152] Specifically, the detection assembly includes a sensing element and a to-be-sensing element, the sensing element can be arranged in the tray 14 of the machine body 1 , and the to-be-sensing element can be arranged on the driving end of the cutter assembly 8 . When the transmission end and the driving assembly are installed normally, the sensing element is located within the detection range of the sensing element, the detection assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com