Spraying method of automatic spraying unit for thin-long structure work piece

A technology for automatic spraying and workpieces, applied in spray booths, spraying devices, etc., can solve problems such as increasing the difficulty of automatic spraying of slender structural workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings (the following description is made with the conveying direction of the elongated structure workpiece 4 as the front).

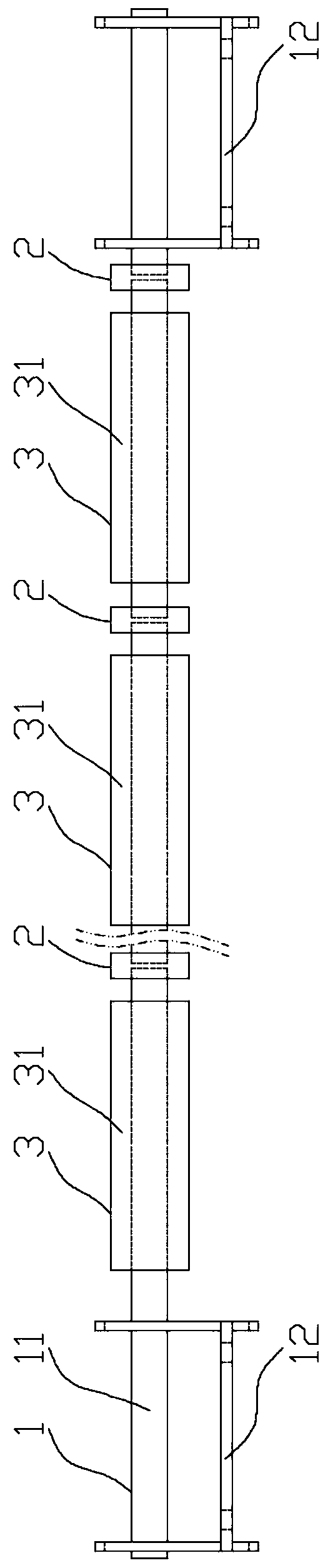

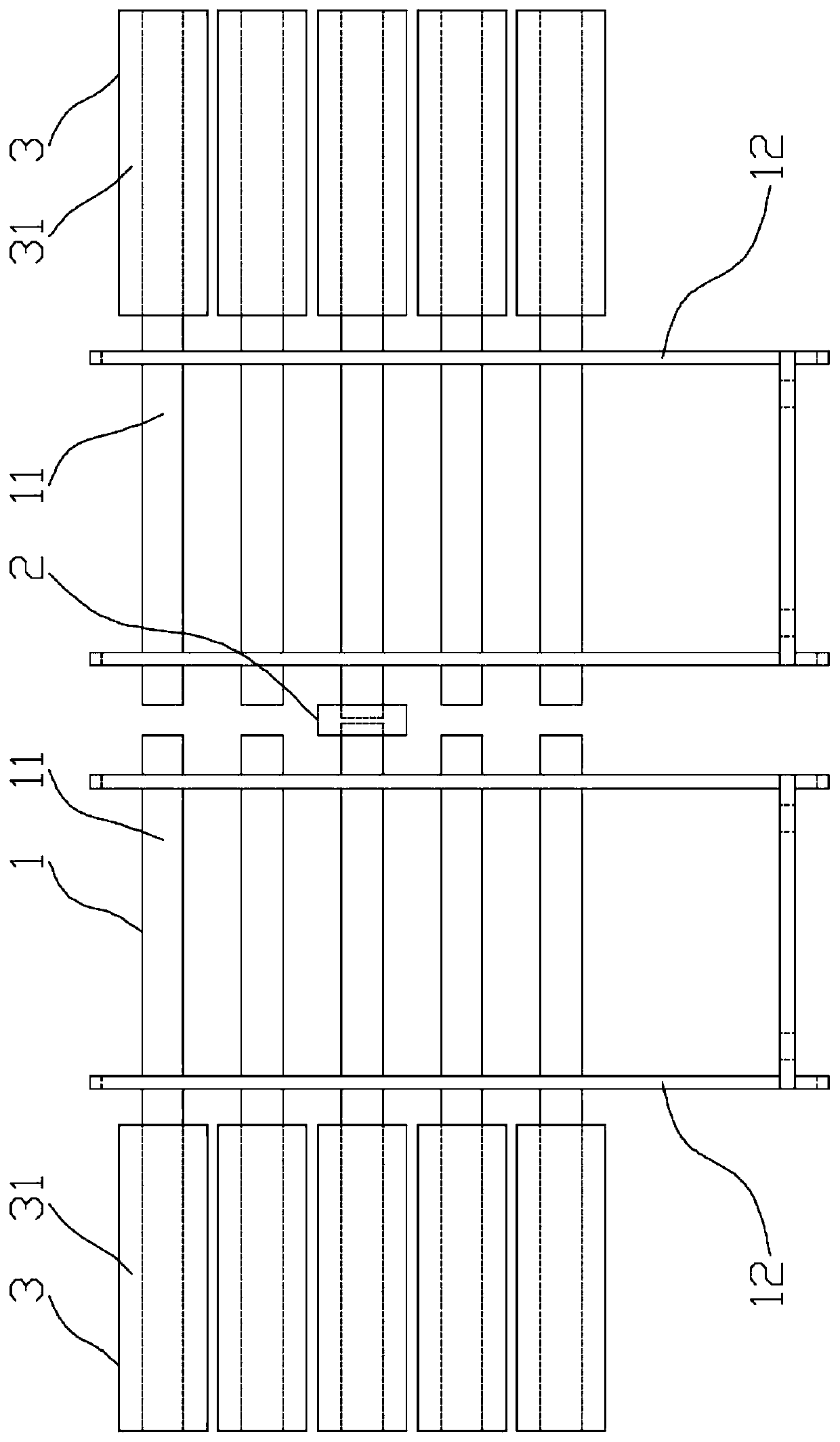

[0033] Such as figure 1 , figure 2 As shown, the automatic spraying production line for the elongated structure workpiece includes a digital conveying unit 1, an automatic spraying unit 2, an automatic drying unit 3 and a centralized electronic control unit.

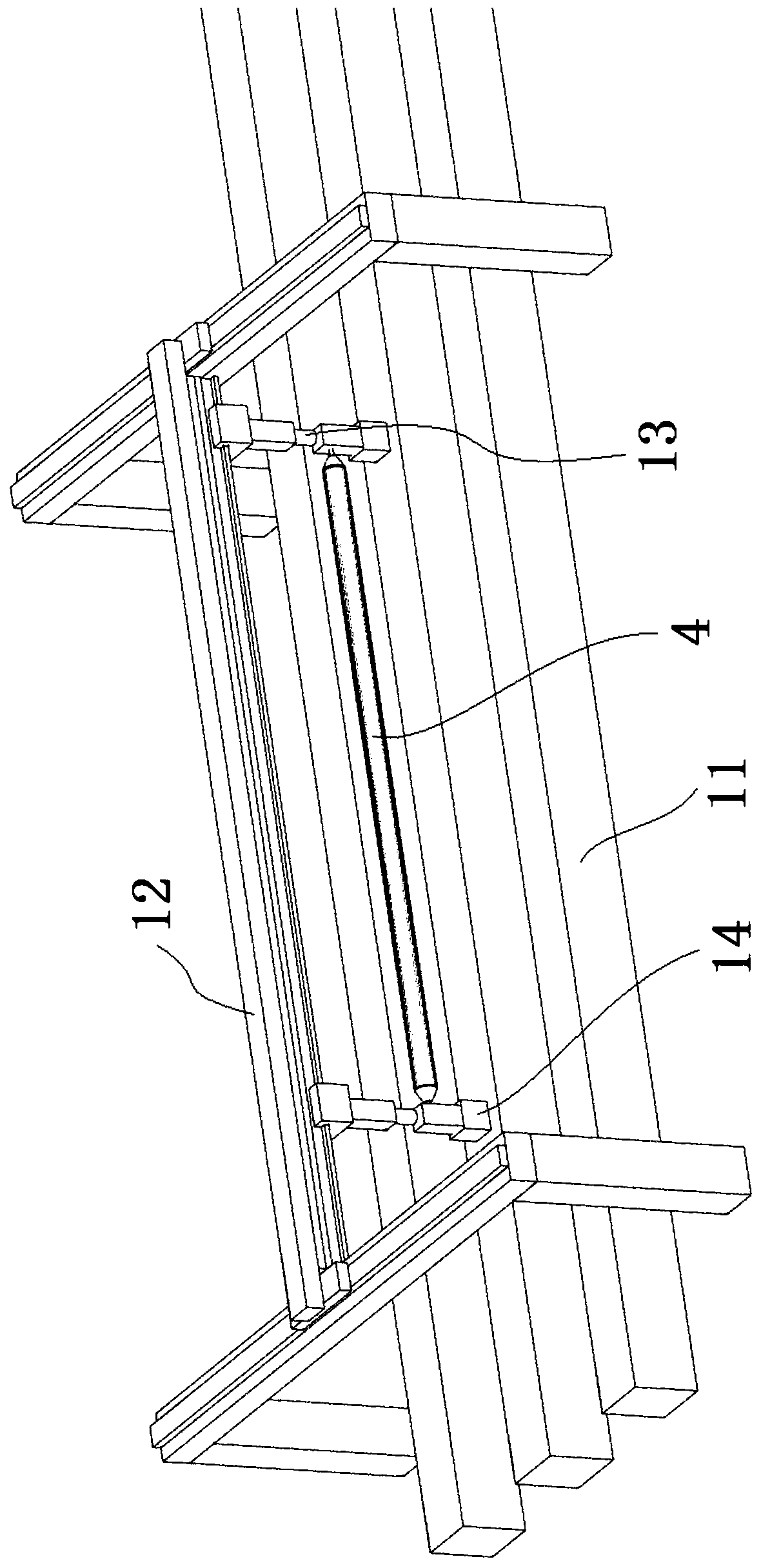

[0034] The digital conveying unit 1 includes a conveying line 11, a work piece picking and placing device, a pallet 14 and a conveying electric control device;

[0035] Such as image 3 As shown, the accompany carriers 14 are arranged in pairs, and the accompany carrier 14 is provided with a workpiece positioning mechanism. For beam-shaped workpieces, the workpiece positioning mechanism can be a positioning clamping structure or a matching positioning pin hole structure, and for rod-shaped workpieces , The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com