Metal wet mold

A wet mold, metal technology, used in heat exchange equipment, fixed plate duct components, heat exchanger types, etc., can solve the problems of large space occupied by the water tank and poor heat dissipation effect, so as to increase the heat dissipation area, improve the cooling speed, and avoid the The effect of taking up more space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

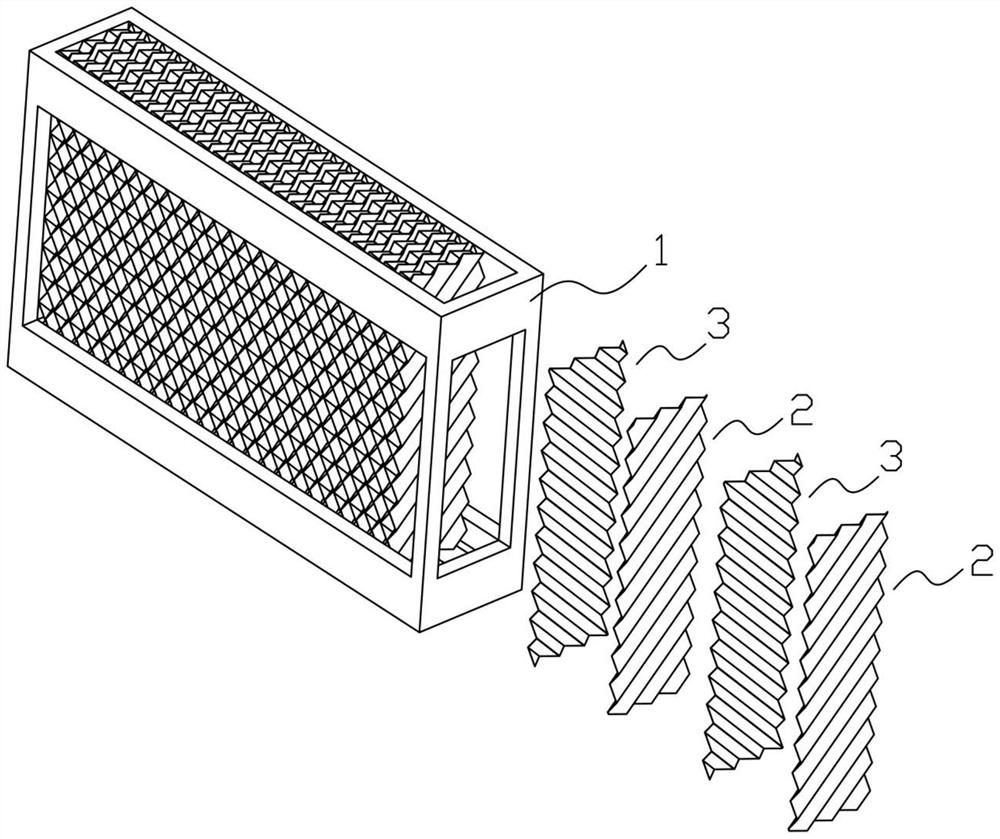

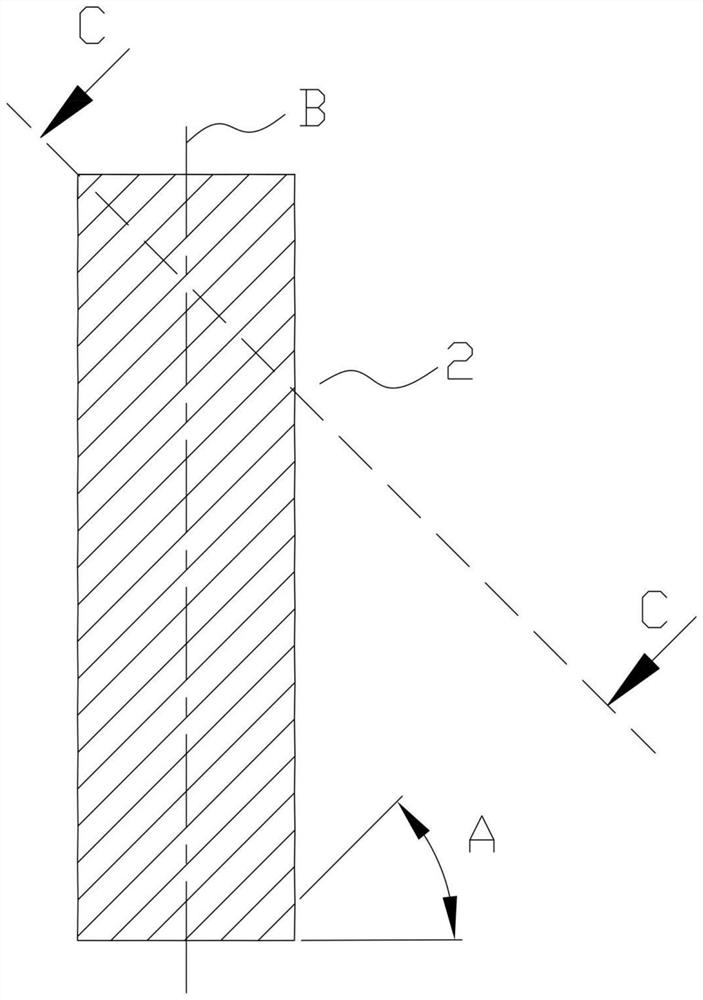

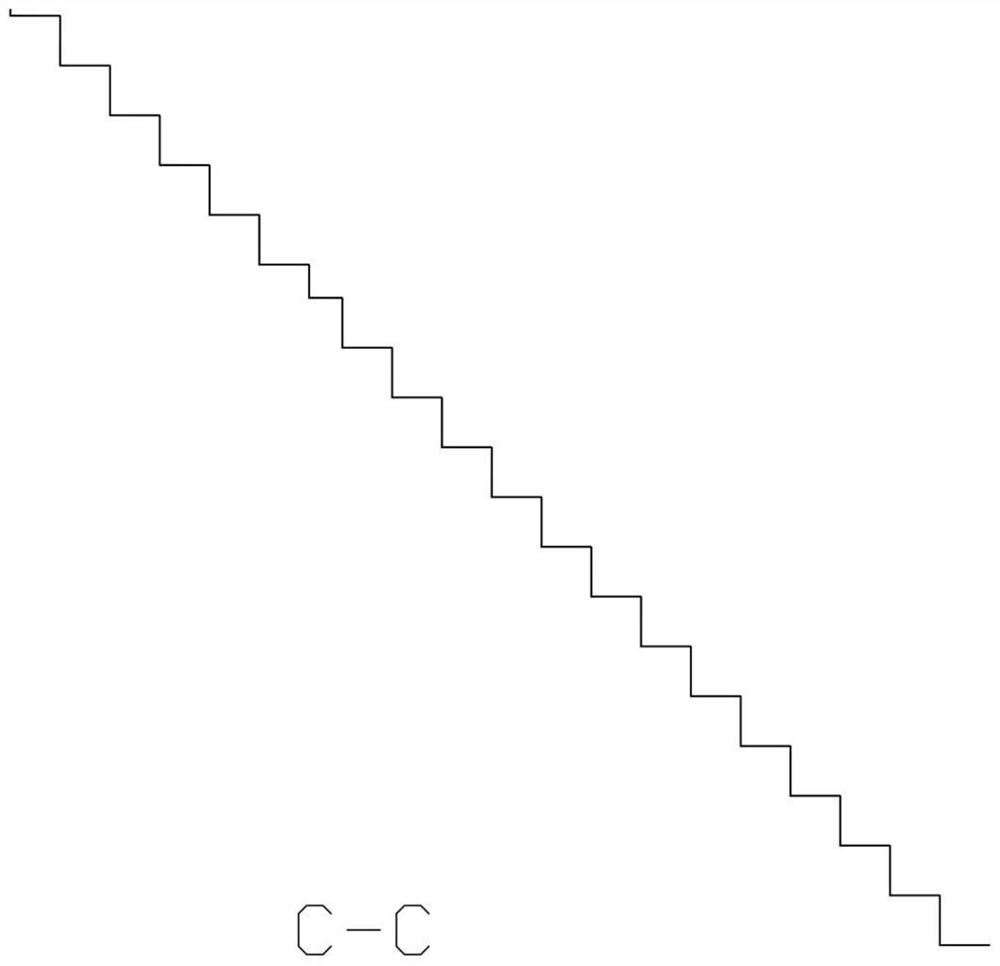

[0020] Please refer to Figure 1 to Figure 3 , a metal wet mold, comprising a frame 1, a plurality of corrugated fins 1 2 and a plurality of corrugated fins 2 3, the corrugated fins 1 2 and corrugated fins 2 3 are rectangular in shape, and the corrugated fins The length and width of heat sink 1 2 and pleated heat sink 2 3 are the same, and the pleated heat sink 1 2 and pleated heat sink 2 3 are all made of metal material to prolong the service life. The metal material is copper foil or stainless steel foil or aluminum foil The pleated heat sink 1 2 is provided with a pleated structure 1, and the pleated radiating fin 2 3 is provided with a pleated structure 2. Both the pleated structure 1 and the pleated structure 2 are set obliquely. When the first and second pleated structures are up, they can move obliquely downward while falling, which not only ensures that the hot wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bevel angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com