An automatic pipe cutting machine

A pipe cutting machine and automatic technology, applied in the field of mechanical processing, can solve the problems of safety impact of workers, difficulty in ensuring cutting accuracy, and difficulty in ensuring cutting quality, etc., to ensure cutting quality, uniform and adjustable feed speed, and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

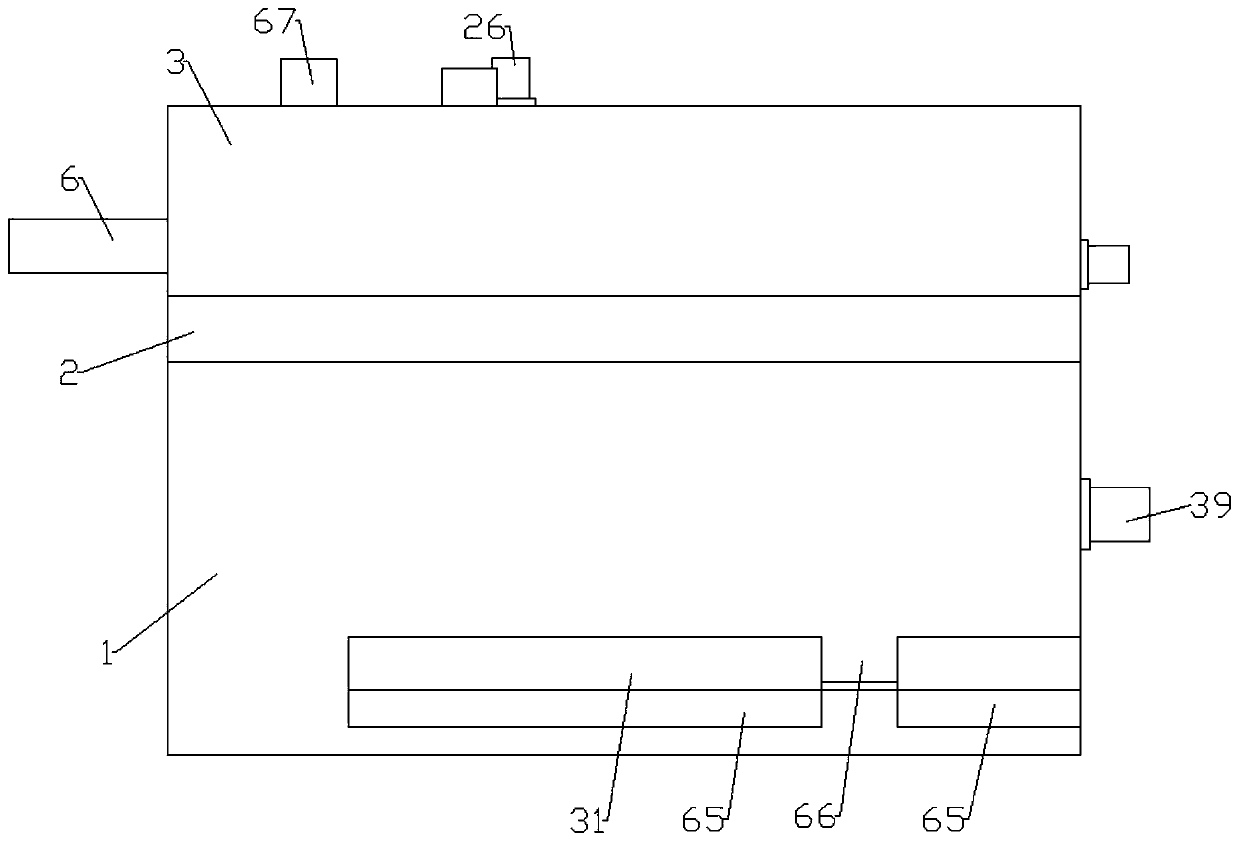

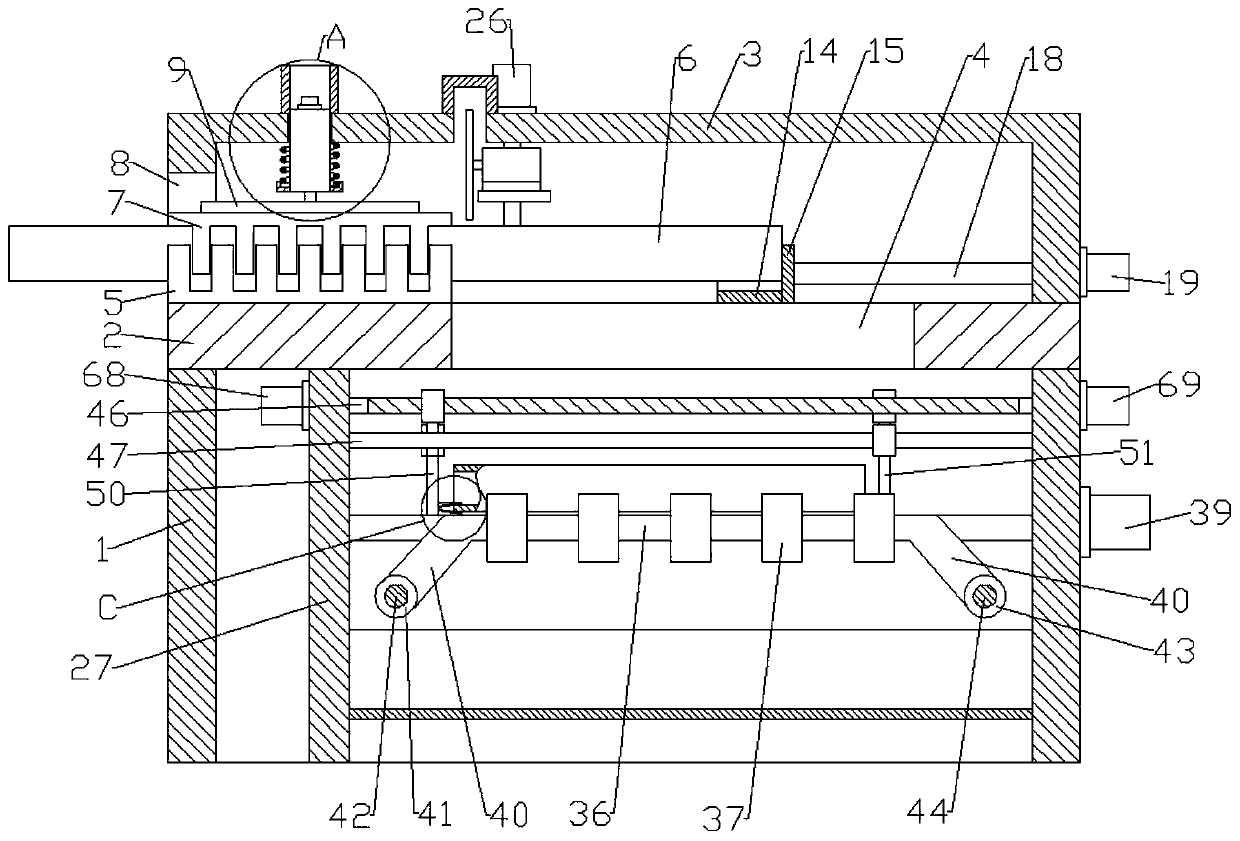

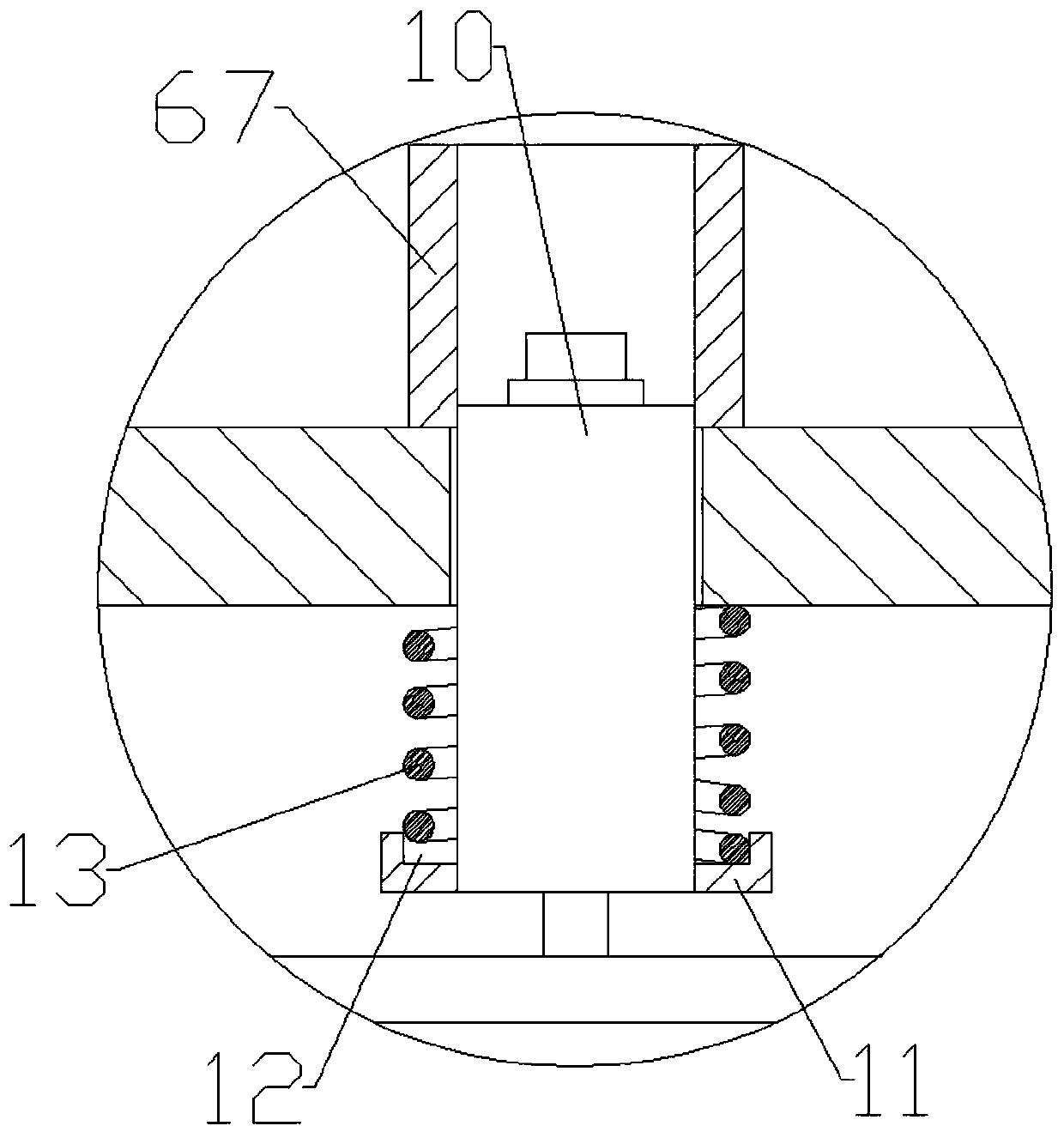

[0027] Refer to attached Figure 1-11 : An automatic pipe cutting machine in this embodiment, comprising a support base 1, the support base 1 is fixedly connected by plates connected end to end, the upper end of the support base 1 is fixedly connected with a working plate 2, and the working plate 2. A sealing cover 3 is fixedly connected to the outer side of the upper end. A blanking opening 4 is opened on the right side of the upper end of the working plate 2. The left end of the blanking opening 4 is provided with a first clamping block 5 fixedly connected to the upper end of the working plate 2. , the upper end of the first clamping block 5 is provided with a steel pipe 6, the upper end of the steel pipe 6 is provided with a second clamping block 7, the left end of the sealing cover is provided with a feed port 8, the first clamping block 5 and The left end of the secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap