Explosion-proof indexing plate

A technology of indexing turntable and indexing plate, which is applied in metal processing mechanical parts, precision positioning equipment, metal processing equipment, etc., can solve the problems of high cost, complex structure of indexing turntable, and difficulty in overall equipment control, and achieve high positioning. Accuracy, the effect of ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

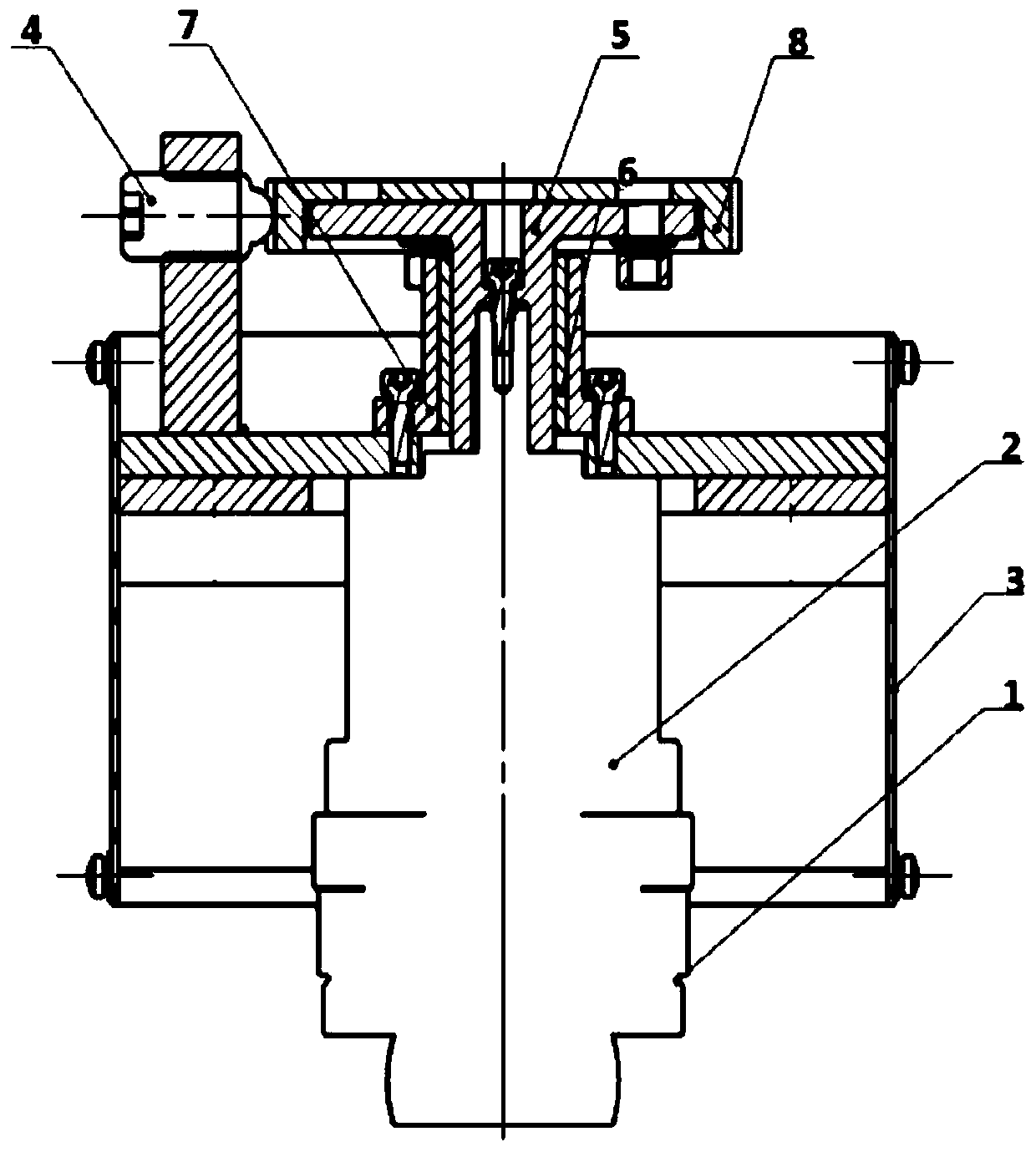

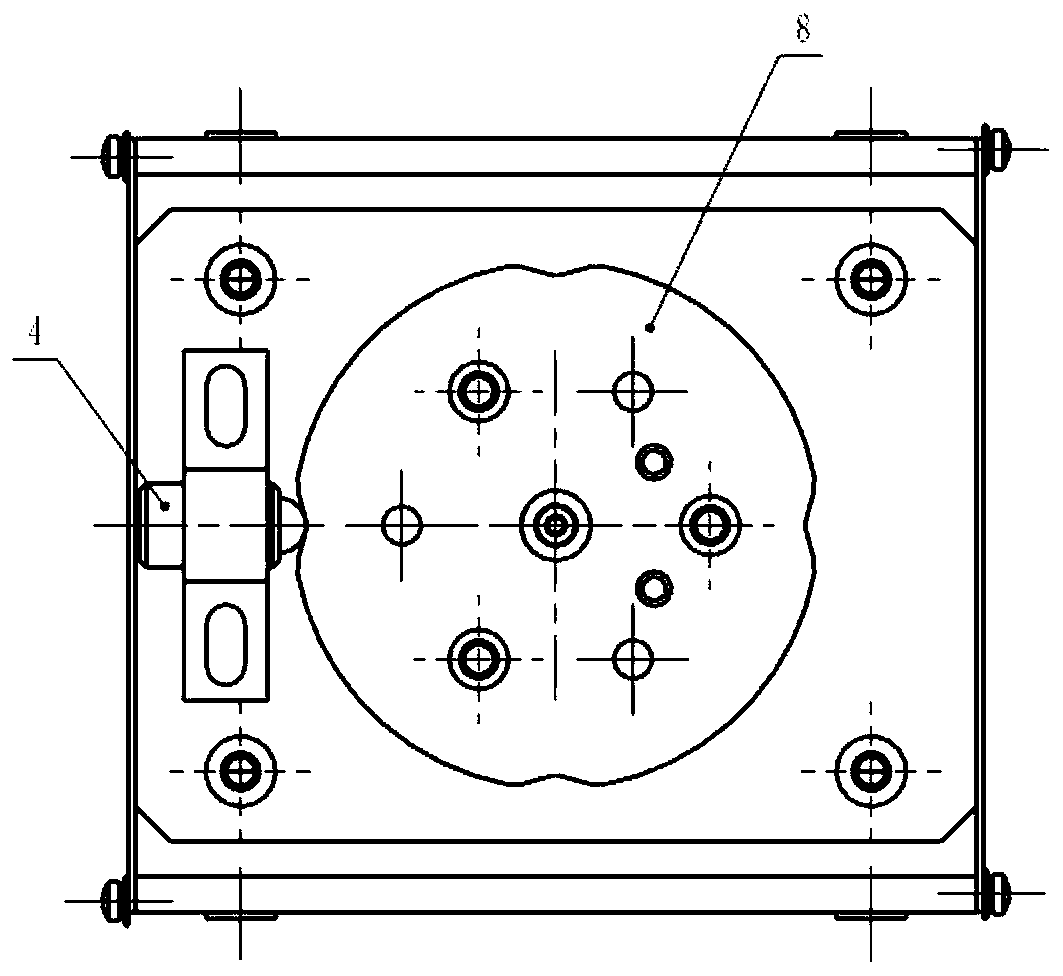

[0025] Such as Figure 1-2 As shown, an explosion-proof indexing turntable includes a positioning device and an indexing plate 8. Several evenly distributed positioning grooves are arranged on the circumference of the indexing plate 8. The positioning device includes a positioning bead 4 and is used for fixing The support of the positioning bead 4, the axis of the length direction of the positioning bead 4 is perpendicular to the axis of the indexing plate 8, the positioning bead 4 is used to be embedded in the positioning groove, the swing cylinder 1 adopts a pneumatic swing cylinder, and the swing cylinder 1 is detachable The connection method is fixed on the base 3; the transmission mechanism includes a ratchet 2 and a flange 5, the flange 5 is in a T-shaped shape, the ratchet 2 is connected to the swing cylinder 1 with a rotating shaft, and the ratchet 2 and the flange 5 adopt a shaft and a hole The shaft of the swing cylinder 1, the ratchet 2, and the flange 5 coincide wi...

Embodiment 2

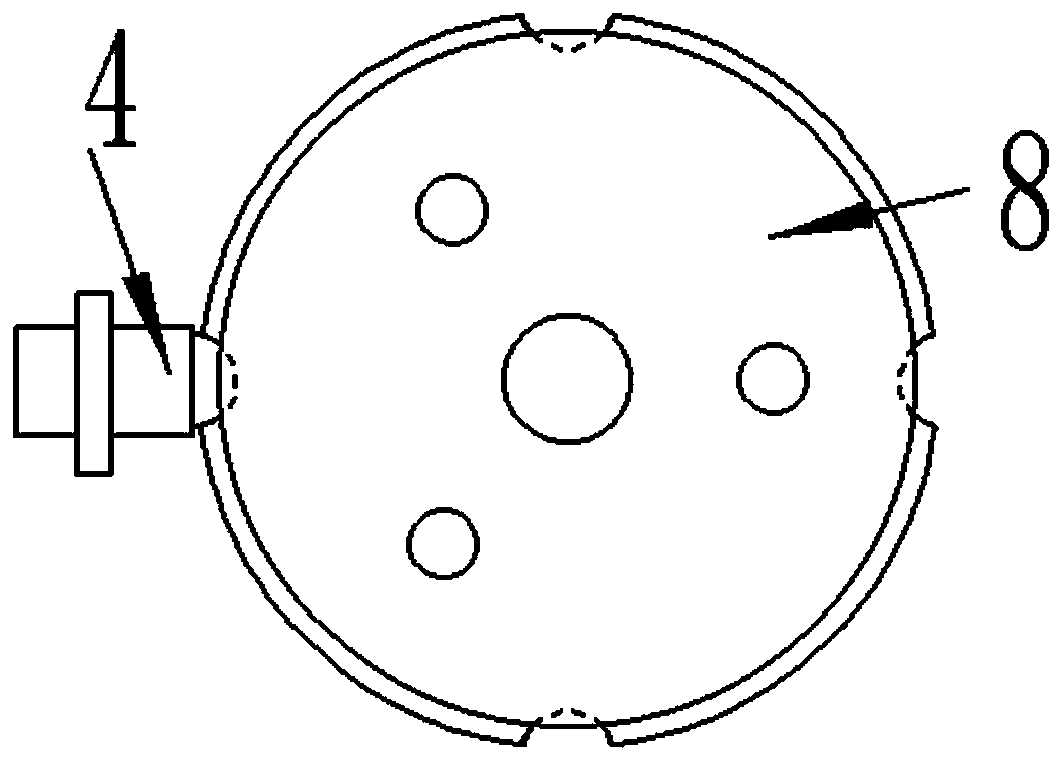

[0028] Present embodiment makes further technical scheme on the basis of embodiment 1: as Figure 3-6 As shown, an annular protruding ring 9 is provided on the circumference of the indexing plate 8, and the cross section of the protruding ring 9 along the radial direction of the indexing plate is concave arc-shaped, and several evenly distributed holes are arranged on the surface of the protruding ring 9 The positioning groove, the connection between the positioning groove and the convex ring 9 is a circular arc curve, so that during the process of the positioning bead 4 being embedded into the positioning groove from the edge of the indexing plate 8, the relationship between the positioning bead 4 and the indexing plate is stable and has no impact. It is beneficial to the accuracy of positioning. Through experimental comparison, it is determined that the depth of the positioning groove is 2-3mm, and if it is less than 2mm, the positioning beads 4 cannot effectively prevent the...

Embodiment 3

[0030] This embodiment is further limited on the basis of Embodiment 1. The swing cylinder adopts a pneumatic swing cylinder with few electrical components, and the indexing can be realized through the cooperation of the index plate and the positioning beads. Compared with the prior art, the structure is simple and the The cost and the difficulty of equipment control are reduced, and it can be used in most places where explosion-proof and explosion-proof are required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com