Ink degassing system of ink-jet 3D printer

A 3D printer and printer technology, applied in the direction of 3D object support structure, additive manufacturing, processing and manufacturing, etc., can solve the problems of unable to eject, clogging the nozzle holes of the print head, and long conveying distance, so as to reduce the scrap rate of equipment and ensure the spraying Smooth ink and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the present invention more thorough and comprehensive.

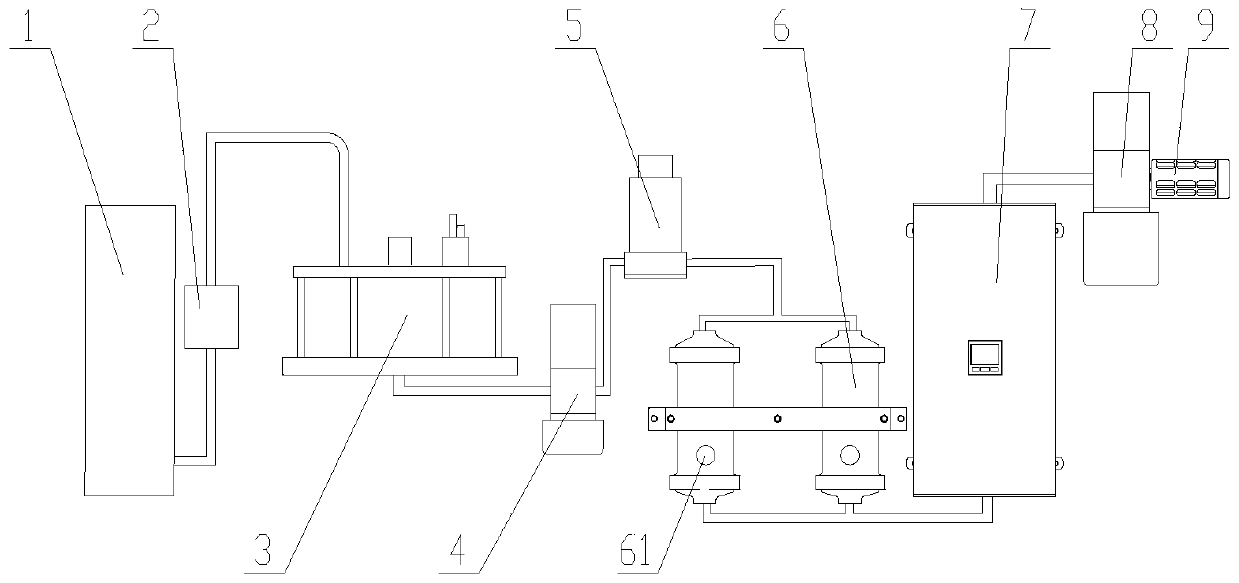

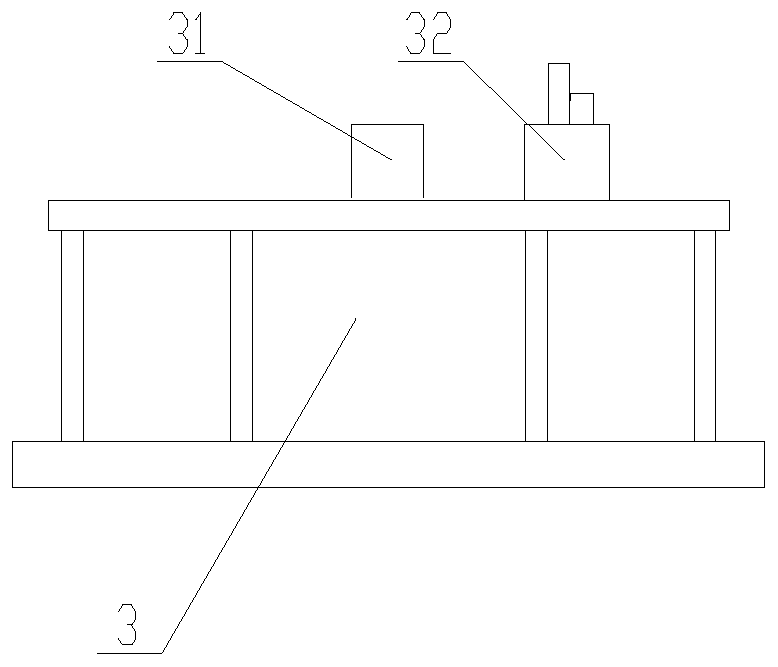

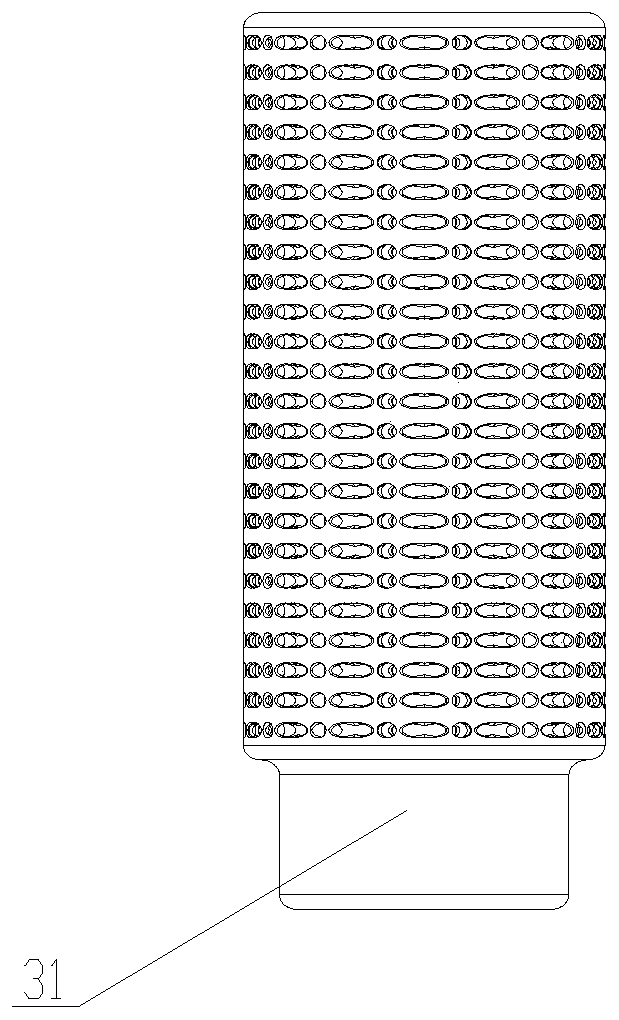

[0020] The overall schematic diagram of an inkjet 3D printer ink degassing system of the present invention is as follows figure 1 shown. Inside the inkjet 3D printer, an ink tank 1, an ink inlet pump 2 and a printing head (not shown in the figure) are arranged. The liquid inlet of ink tank 1 and ink inlet pump 2 is connected with pipeline, and the liquid outlet of ink inlet pump 2 is connected with ink cartridge 3 through pipeline, and the liquid outlet of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com