Label production device and production process

A production device and labeling technology, applied in transportation and packaging, winding strips, sending objects, etc., can solve problems such as wrinkles, affecting the aesthetics of labels, and difficult peeling of release paper and face paper, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present application. .

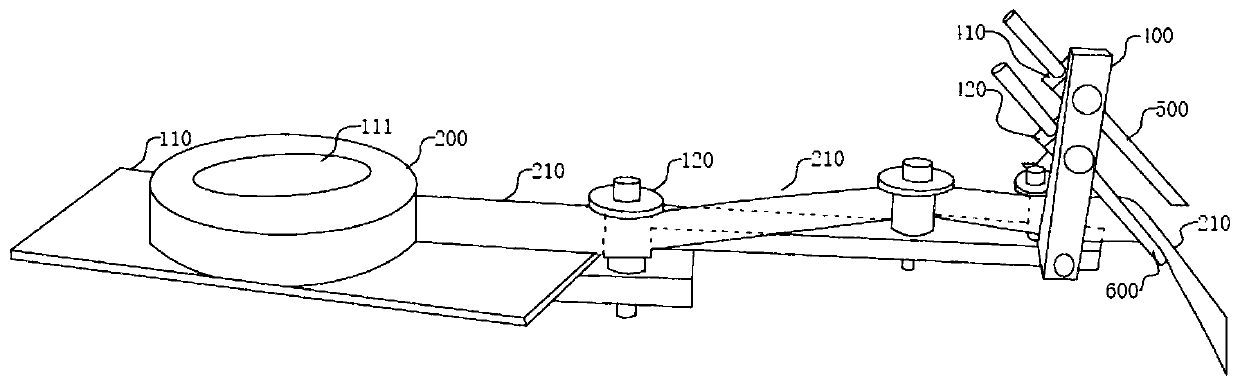

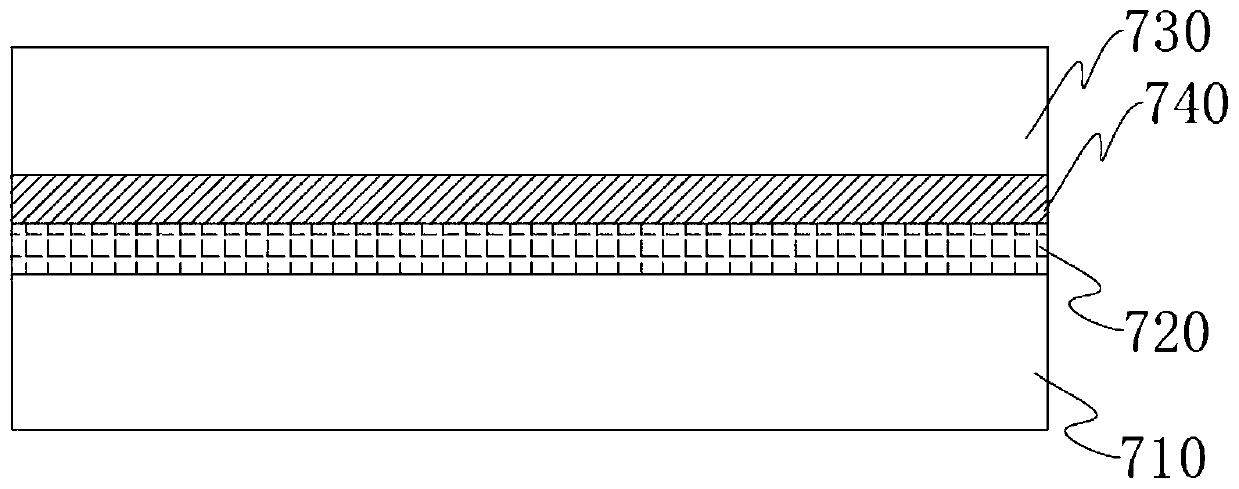

[0039] Please refer to figure 1 It is a structural schematic diagram of the first embodiment of the present application, the label includes a release paper and a face paper that is peelably pasted on the release paper, and a peelable non-stick strips firmly attached to the tissue paper.

[0040] The production device includes a separation rod 500 and an introduction rod 600 arranged on the same side of the label transmission direction; the separation rod 500 and the introduction rod 600 are arranged successively in the transmission direction of the label; in this embodiment, the label is from top to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com