A kind of manufacturing method of tempered vacuum glass

A technology of vacuum glass and manufacturing method, which is applied in glass forming, glass remolding, glass manufacturing equipment, etc., can solve the problem of reduced peripheral strength of tempered flat glass, difficulty in making multi-vacuum-layer vacuum glass, low safety performance of vacuum glass, etc. problems, to achieve excellent safety and reliability, excellent thermal insulation performance, and reduce thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

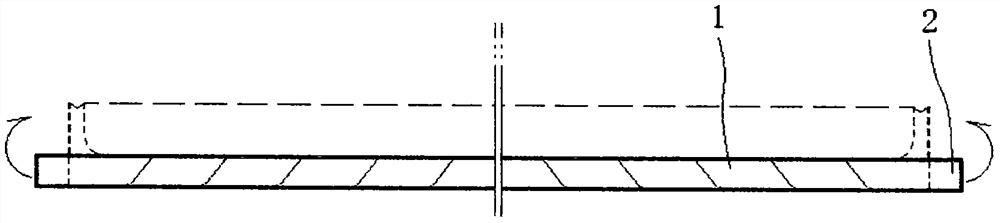

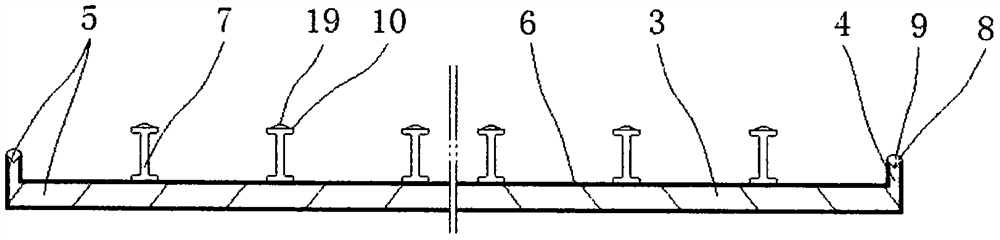

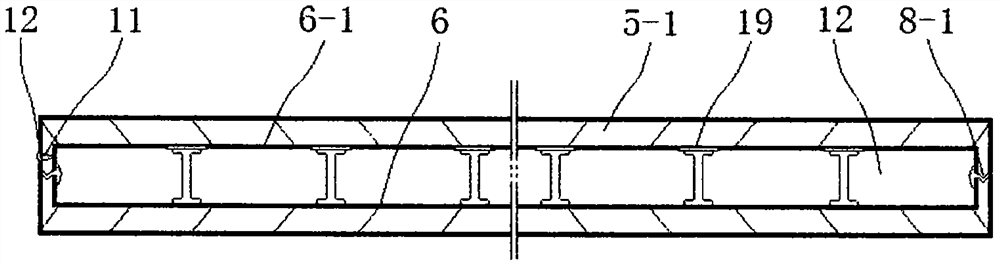

[0058] Embodiment one: according to figure 1 , figure 2 , image 3 Shown to make:

[0059] (1) Firstly, the flat glass or float glass 1 is preheated at a temperature gradually increased to 280°C-320°C.

[0060] (2) Partially heat the periphery 2 of flat glass and float glass to a softening temperature of 650°C-1150°C, which can be formed, and then bend the softened glass periphery 2 in a direction that forms a certain angle with the glass plane, Form the edged glass. And keep the flatness of the glass surface from being affected by heating and edge folding.

[0061] (3) Tempering the edged glass to form a tempered edged glass 5 with a single side opening formed by the face wall 3 and the side wall 4 .

[0062] (4) Place the tempered folded glass 5 with the opening upward, and place the pin 7 at the corresponding position on the inner surface 6 of the facing wall.

[0063] (5) Place the melted sealing low-temperature sealing material 9 on the sealing surface 8 of the sid...

Embodiment 2

[0066] Embodiment two: according to Figure 4 Shown to make:

[0067] (1) Preheat the tempered edged glass 5 at a temperature of 280°C-300°C, and then place the pin 7 at the corresponding position on the inner surface 6 of the facing wall, then place the separation layer 13 on the upper surface 10 of the pin, and make The periphery 14 of the separation layer is placed on the inner edge of the side wall sealing surface 8 or connected to the inner edge of the side wall sealing surface.

[0068] (2) Place the second layer pins 7 - 1 at corresponding positions on the surface 15 of the separation layer, so that the second layer pins 7 - 1 are aligned up and down with the first layer pins 7 .

[0069] (3) Place the melted sealing low-temperature sealing material 9 on the side wall sealing surface 8, so that the sealing low-temperature sealing material 9 is connected to the periphery 14 of the separation layer, and completely wraps between the periphery 14 of the separation layer an...

Embodiment 3

[0071] Embodiment three: according to Figure 5 Shown to make:

[0072] (1) After placing the pin 7 at the corresponding position on the inner surface 6 of the facing wall, place the separation layer 13 on the upper surface 10 of the pin, and make the inner surface 16 of the side wall around the periphery 14 of the separation layer meet.

[0073] (2) At the periphery where the periphery of the separation layer 14 is connected to the inner surface 16 of the side wall, a low-temperature sealing material 17 for the separation layer with a melting temperature of 300° C. to 500° C. is placed, so that the periphery of the separation layer 14 is hermetically sealed on the side wall. The inner surface of the wall 16 .

[0074] (3) Place the second-layer column pins 7-1 at corresponding positions on the surface 15 of the separation layer, so that the second-layer column pins 7-1 and the first-layer column pins 7 are aligned up and down. Repeat (1)(2)(3) item assembling method, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com