Guide rail connecting device

A technology for connecting devices and guide rails, applied in fluid pressure actuation devices, geophysical measurements, instruments, etc., can solve problems such as low efficiency and safety, difficult connection, long time required to connect guide rails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

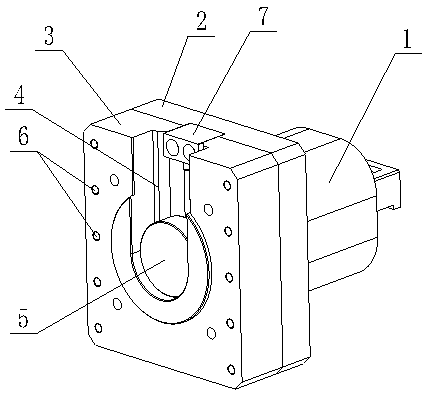

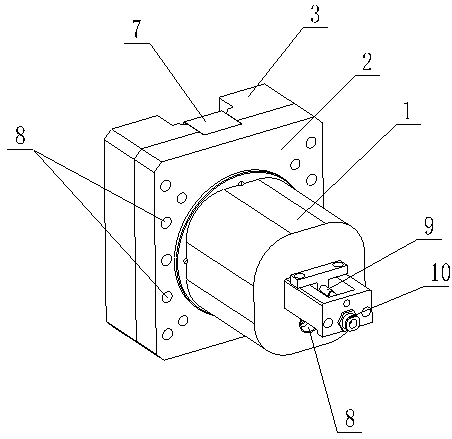

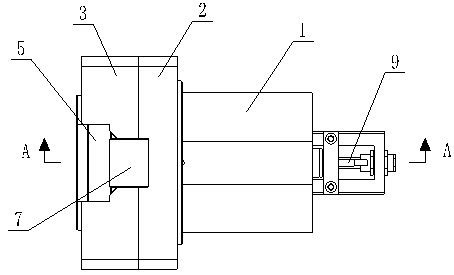

[0015] For specific examples, see Figure 1-4 , a rail connection device, including a device body 1, a main disc 2 and a tool disc 3, the front end of the device body 1 is fixed with the main disc 2, and the rear side of the device body 1 is provided with an oil injection hole 19, the The periphery of the main disk 2 is provided with a plurality of main disk fixing holes 8, and the corresponding main disk 2 is provided with a tool disk 3, and the periphery of the tool disk 3 is provided with a plurality of tool disk fixing holes 6, and the tool disk 3 is provided with There are clamping protrusions 4, the main disc 2 is provided with a main disc positioning block 7 and a positioning pin 11, a piston 13 is provided in the device body 1, and a piston rod 12 is provided in the center of the device body 1, so that The piston rod 12 passes through the piston 13, the connection between the piston rod 12 and the piston 13 is provided with a clamping step 20, and the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com