Detection device for annular multi-surface prism

A multi-faceted prism and detection device technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of high cost, large space occupation, low efficiency, etc., and achieve the effect of low cost, small space occupation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

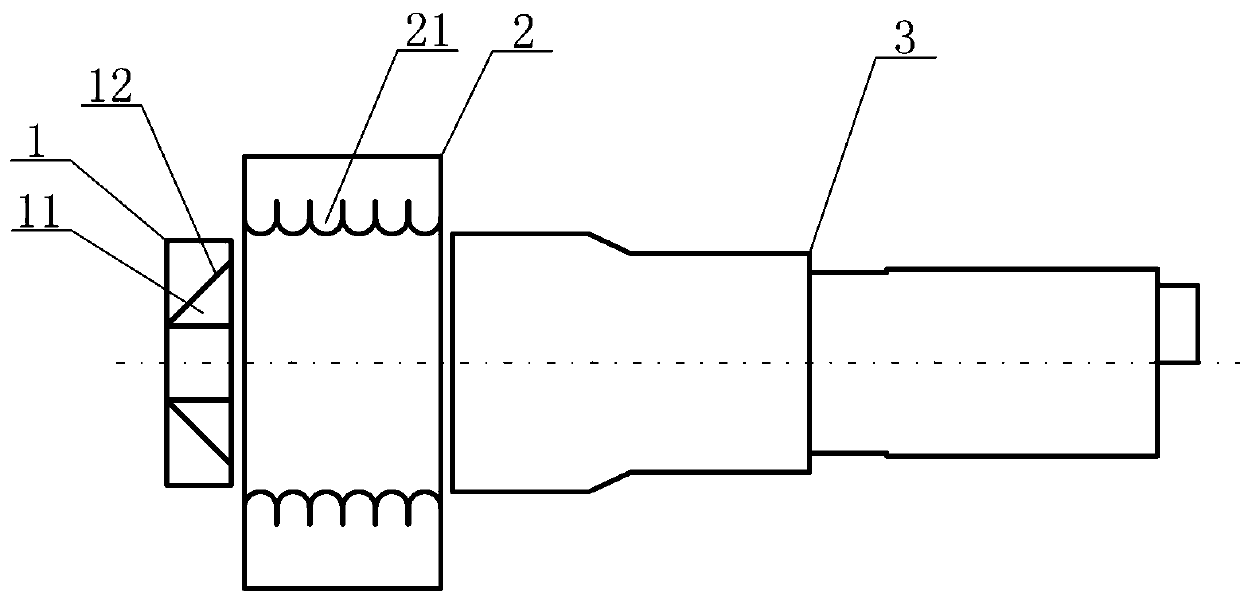

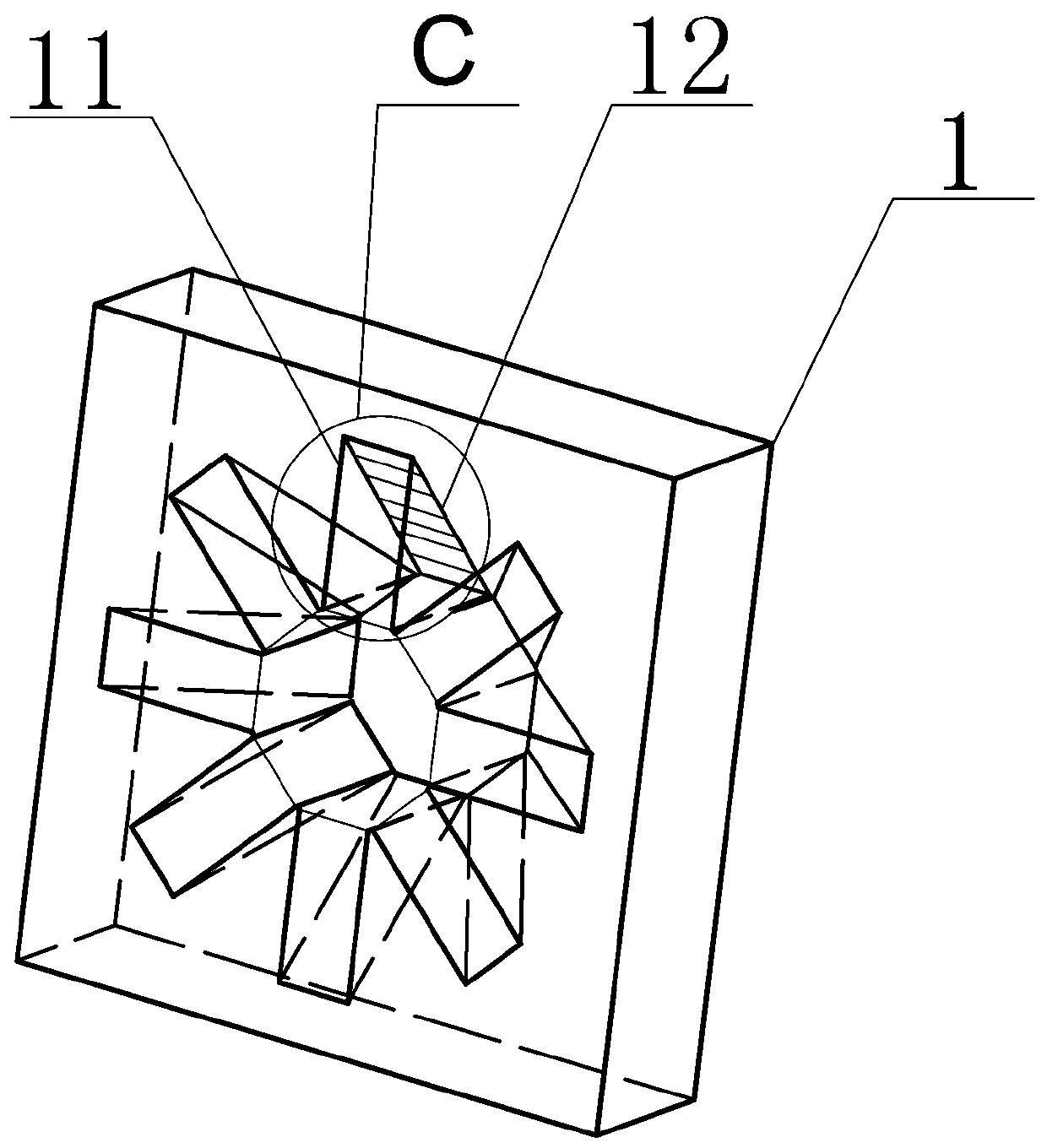

[0015] refer to figure 1 , figure 2 , image 3 , the present invention includes a polygonal prism 1, a light source 2 and an industrial camera 3;

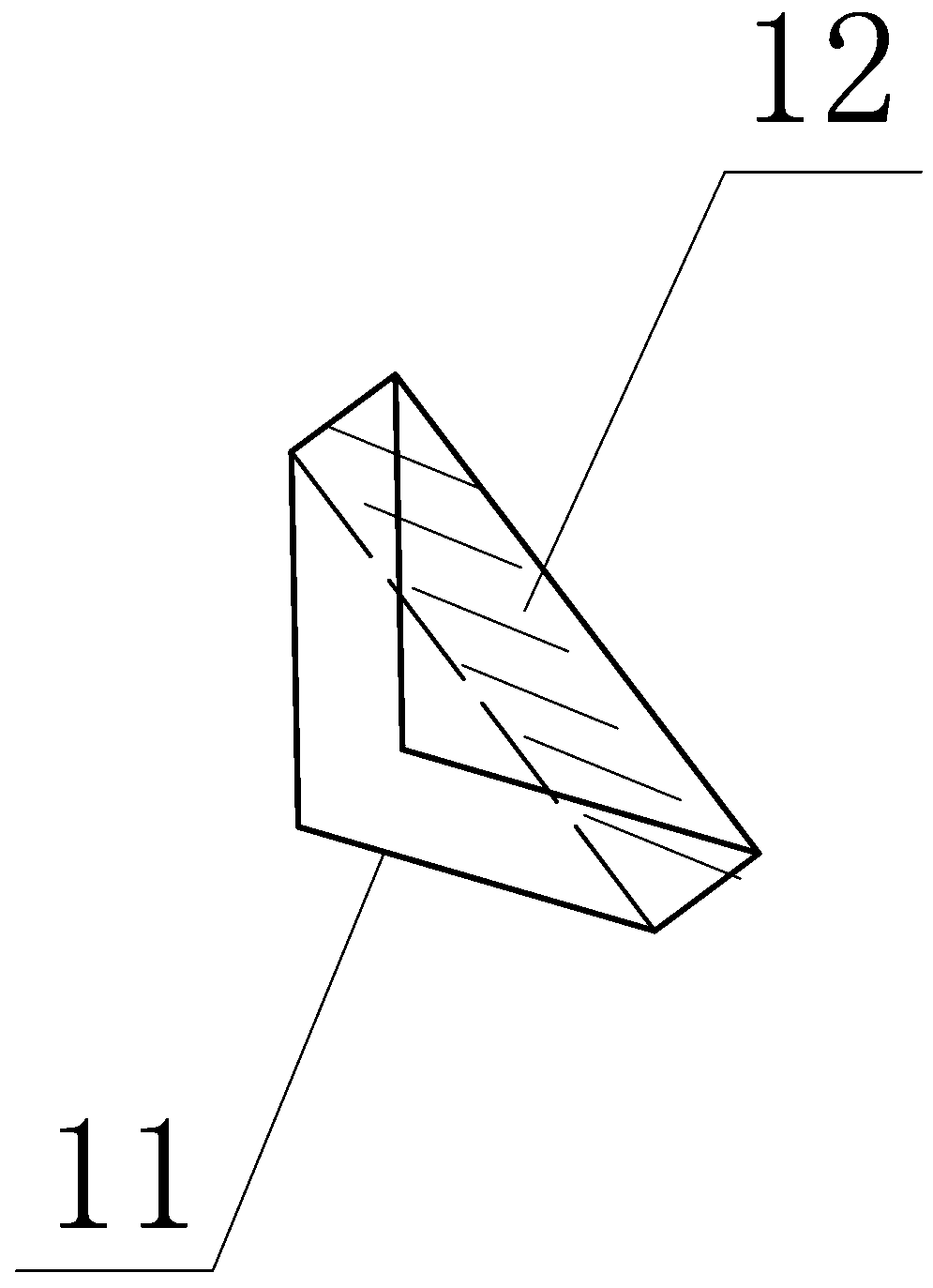

[0016] Described polyhedral prism 1 is made of prism base 11 and reflecting mirror 12, and prism base 11 is a rectangular body, and the rectangular body is provided with the hole of octagon along the axis, and each limit of octagon is all provided with the reflection of a plane. The mirror seat, the angle between the plane where the reflector seat is located and the axis is 45°, and the reflector 12 is eight pieces, which are respectively attached to each reflector seat of the octagon. The light source 2 is a cylindrical part, and the light source 2 Illumination lamps 21 are evenly distributed along the circumference on the cylindrical inner wall; the polygonal prism 1 , light source 2 and industrial camera 3 are arranged in sequence along the axis of the prism base 11 .

[0017] Embodiment of the invention

[0018] In the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com