Petrochemical inspection robot and working method thereof

An inspection robot and petrochemical technology, applied in the field of robots, can solve the problems of low inspection efficiency and incomplete inspection, and achieve the effect of accurate inspection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

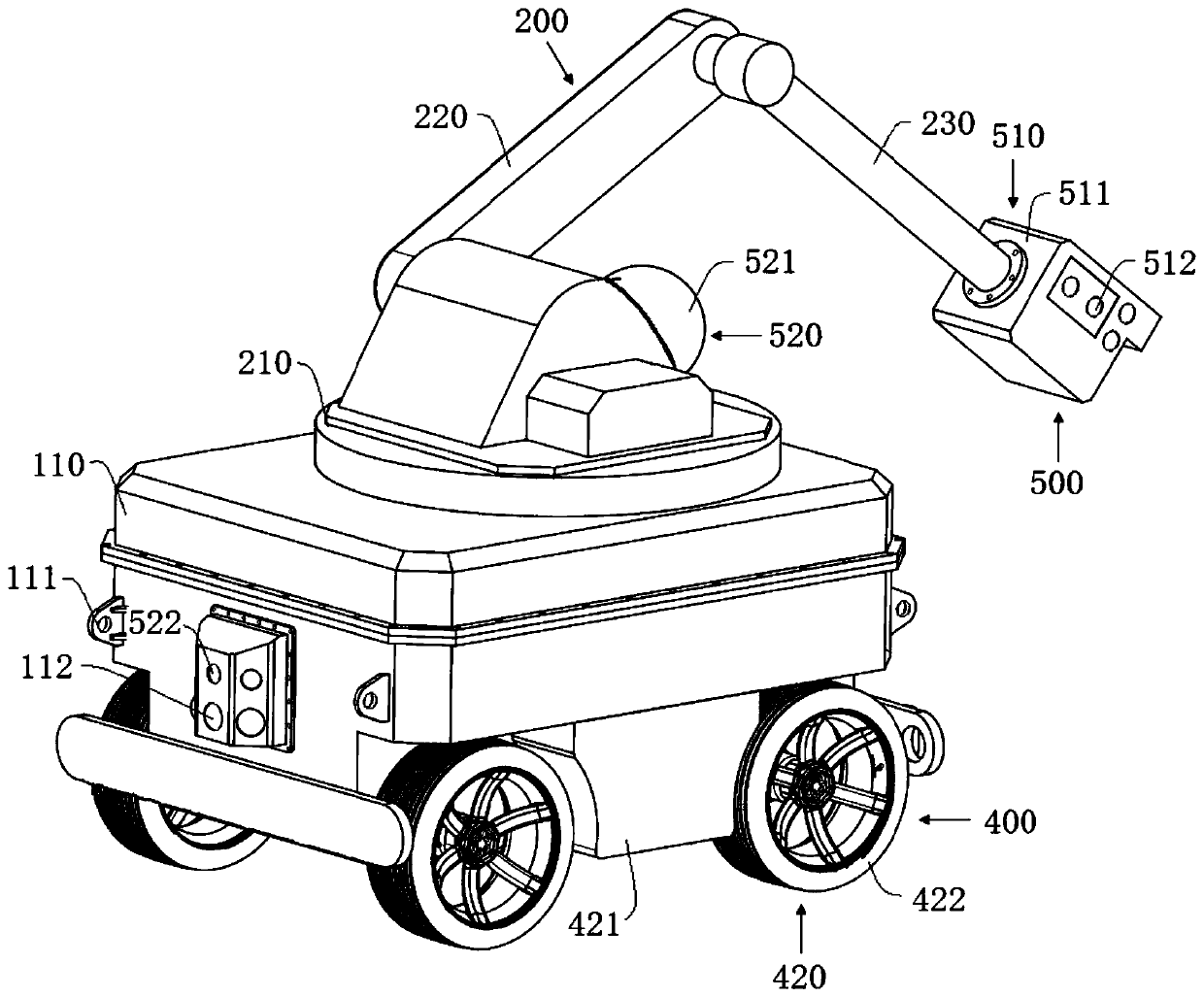

[0057] Such as figure 1 As shown, a petrochemical inspection robot in this embodiment includes a chassis 100 , a folding boom device 200 , a power and driving device 400 , a control device 300 , a power and driving device 400 , and a data acquisition and monitoring device 500 . The control device 300 and the power and drive device 400 are arranged on the chassis 100, and the folding boom device 200, the power and drive device 400, and the data acquisition and monitoring device 500 are respectively electrically connected to the control device 300, and are uniformly controlled by the control device 300.

[0058] On the chassis 100, an outer shield 110 is engaged on the chassis 100. The outer shield 110 is made of sheet metal and is welded on the chassis 100. The outer shield 110 as a whole consists of two rectangular parallelepipeds that lack one side and engage the missing side. It is made by fixing with bolts and snapped on the chassis 100 . The machine parts of the entire ro...

Embodiment 2

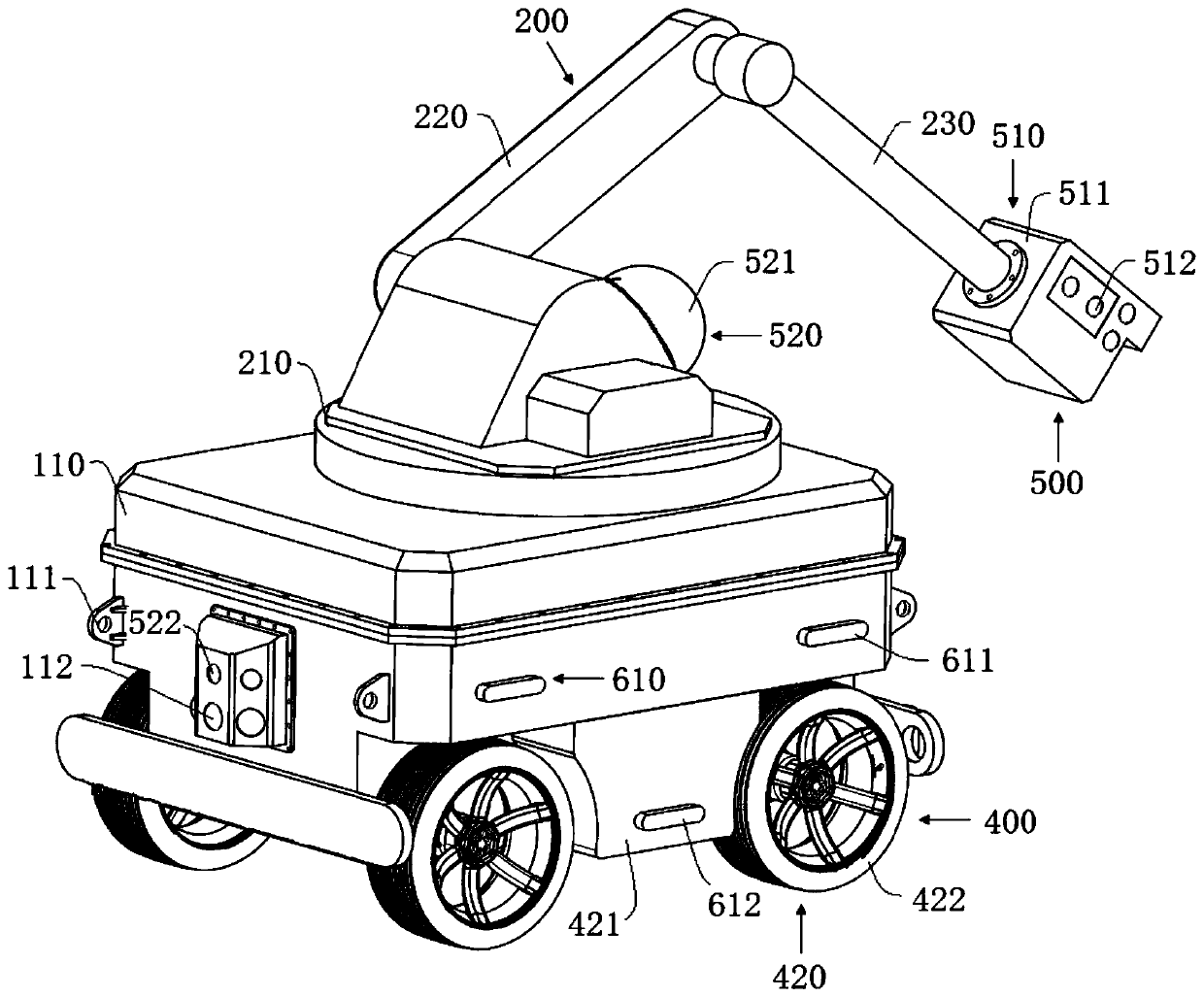

[0073] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that a solution is proposed for the situation that the petrochemical inspection robot cannot perform reasonable and effective obstacle avoidance in the complex environment of the petrochemical plant.

[0074] Such as figure 2 As shown, an obstacle avoidance inspection robot of this embodiment includes a chassis 100, a folding boom device 200, a power and driving device 400, a control device 300, a power and driving device 400, a data acquisition and monitoring device 500, and a safety and explosion-proof device 600. The control device 300 and the power and drive device 400 are arranged on the chassis 100, the folding boom device 200, the power and drive device 400, the data acquisition and monitoring device 500, and the safety and explosion-proof device 600 are respectively electrically connected to the control device 300, and the control device 300 unified management and...

Embodiment 3

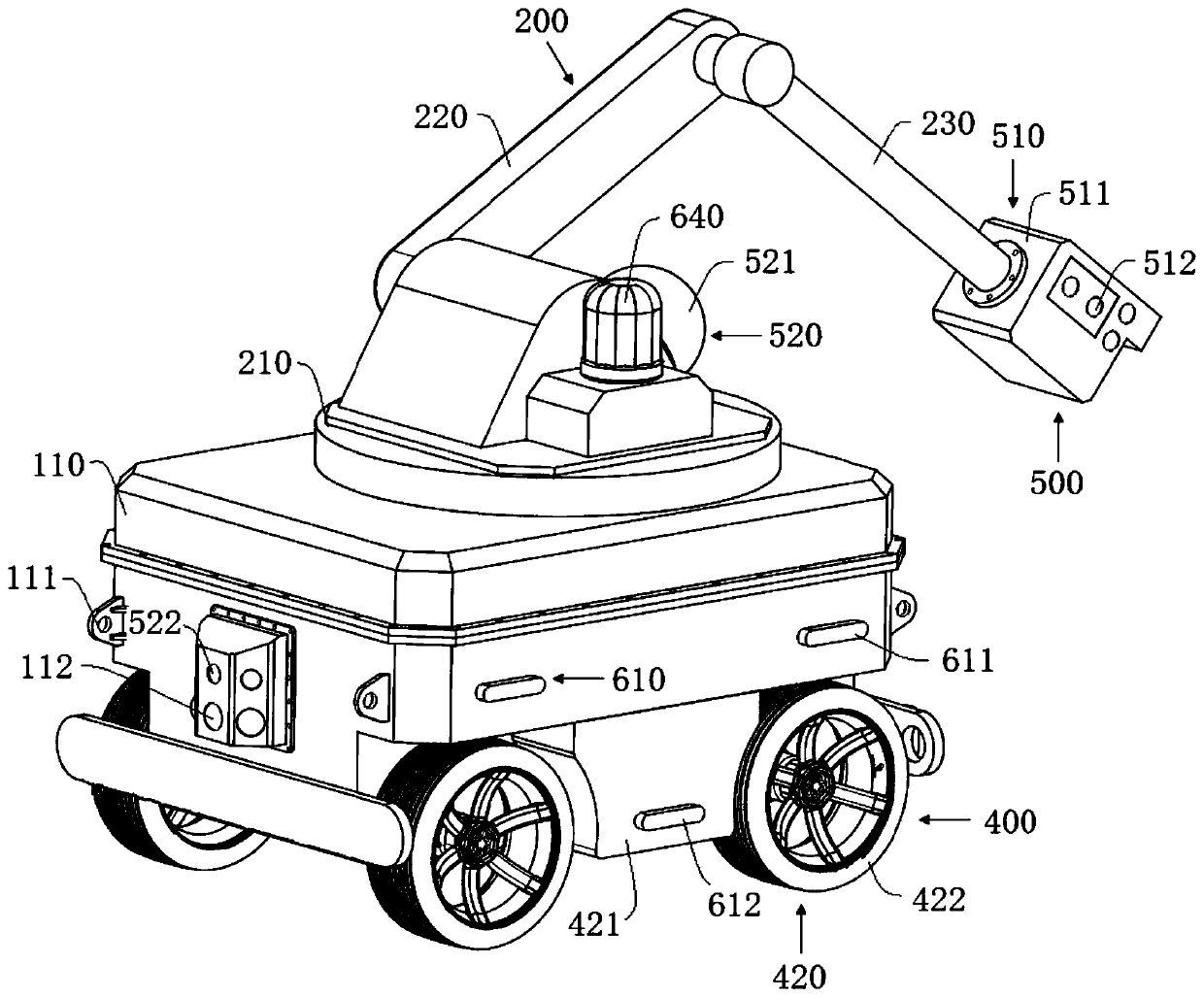

[0083] The structure of this embodiment is basically the same as that of Embodiment 2. The difference is that a solution is proposed for the situation that the petrochemical inspection robot cannot provide safety warnings for emergencies in the complex environment of petrochemical plants.

[0084] Such as image 3 As shown, a safety warning inspection robot of this embodiment includes a chassis 100, a folding boom device 200, a power and driving device 400, a control device 300, a power and driving device 400, a data acquisition and monitoring device 500, and a safety and explosion-proof device 600. The control device 300 and the power and drive device 400 are arranged on the chassis 100, the folding boom device 200, the power and drive device 400, the data acquisition and monitoring device 500, and the safety and explosion-proof device 600 are respectively electrically connected to the control device 300, and the control device 300 unified management and control.

[0085] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com