Sensor installation device for acoustic wind tunnel test

A technology of wind tunnel test and installation device, applied in aerodynamic test, measurement device, instrument and other directions, to achieve the effect of light weight, good function expansibility and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

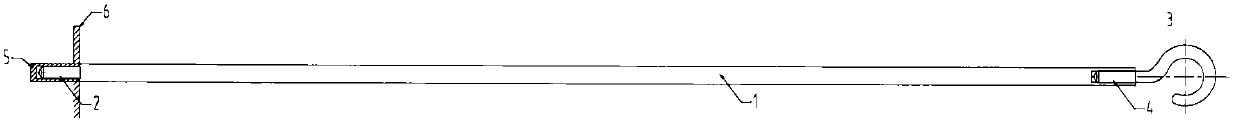

[0022] Embodiment 1 (one-dimensional wire mesh alignment device)

[0023] exist figure 1 In the first embodiment shown, it reflects the form of the wire mesh array device used when the sensors are arranged in a one-dimensional line array. The wire mesh array device is composed of a connecting rod (1) and a steel wire rope (2), wherein the connecting rod needs to have a certain length, which is slightly higher than the sound-absorbing wedge (4). After the wire mesh array device is installed, required sensors, such as sound pressure sensors, can be installed at the measuring point (3). In Embodiment 1, there are a total of 5 measuring points where sensors can be installed to form a one-dimensional line array arrangement, which can measure various signal data at positions parallel to the axis of the wind tunnel, such as sound pressure signals. The specific connection method is as Figure 4 ~ Figure 6 shown.

[0024] figure 2 As shown in the connecting rod installation diagr...

Embodiment 2

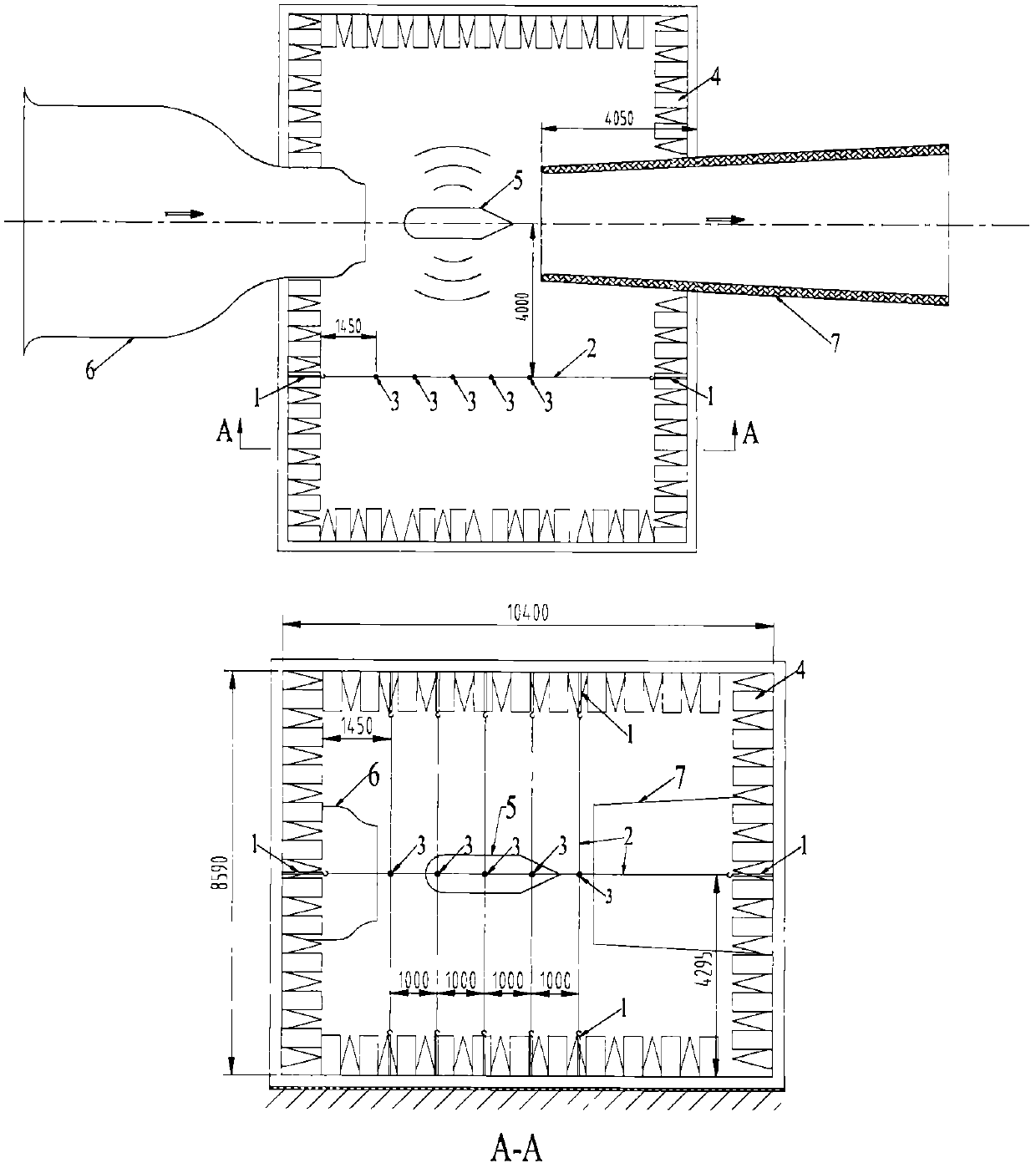

[0028] Embodiment 2 (two-dimensional wire mesh alignment device)

[0029] exist Figure 5 In the second embodiment shown, it reflects the form of the wire mesh array device used when the sensors are arranged in a two-dimensional plane array. The wire mesh array device is composed of a connecting rod (1) and a steel wire rope (2), wherein the connecting rod needs to have a certain length, which is slightly higher than the sound-absorbing wedge (4). After the wire mesh array device is installed, the required sensors can be installed at the measuring point (3). In the second embodiment, there are a total of 5×5=25 measuring point locations available for installing sensors, forming a two-dimensional planar array layout, which can measure various signal data at the planar positions parallel to the axis of the wind tunnel.

Embodiment 3

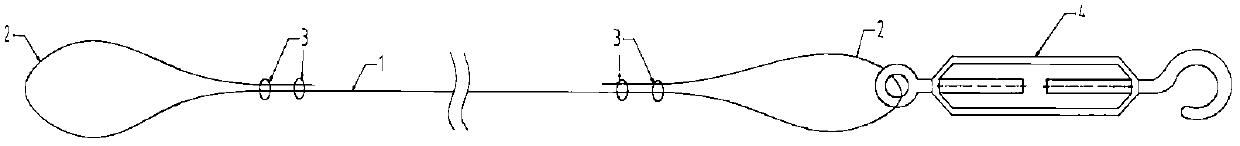

[0030] Embodiment three (three-dimensional wire mesh arrangement device)

[0031] exist Figure 6In the third embodiment shown, it reflects the form of the wire mesh array device used when the sensors are arranged in a three-dimensional space array. The wire mesh array device is composed of a connecting rod (1) and a steel wire rope (2), wherein the connecting rod needs to have a certain length, which is slightly higher than the sound-absorbing wedge (4). After the wire mesh array device is installed, the required sensors can be installed at the measuring point (3). In the third embodiment, there are a total of 5×5×3=75 measuring point positions available for installing sensors, forming a three-dimensional space array layout, which can measure various signal data in the space field on the side of the wind tunnel axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com