Tensile test device and heating device

A technology for tensile testing and heating devices, applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

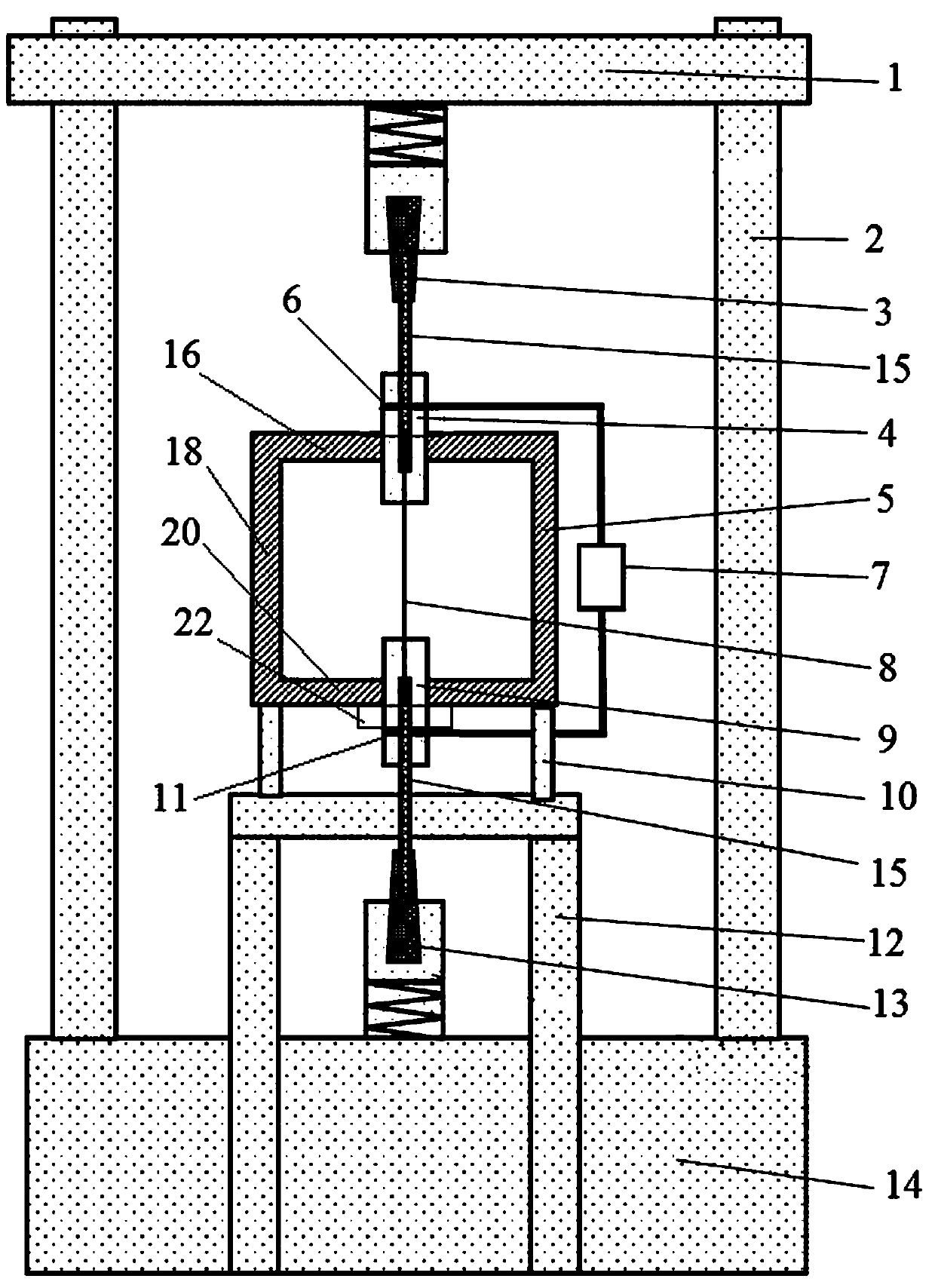

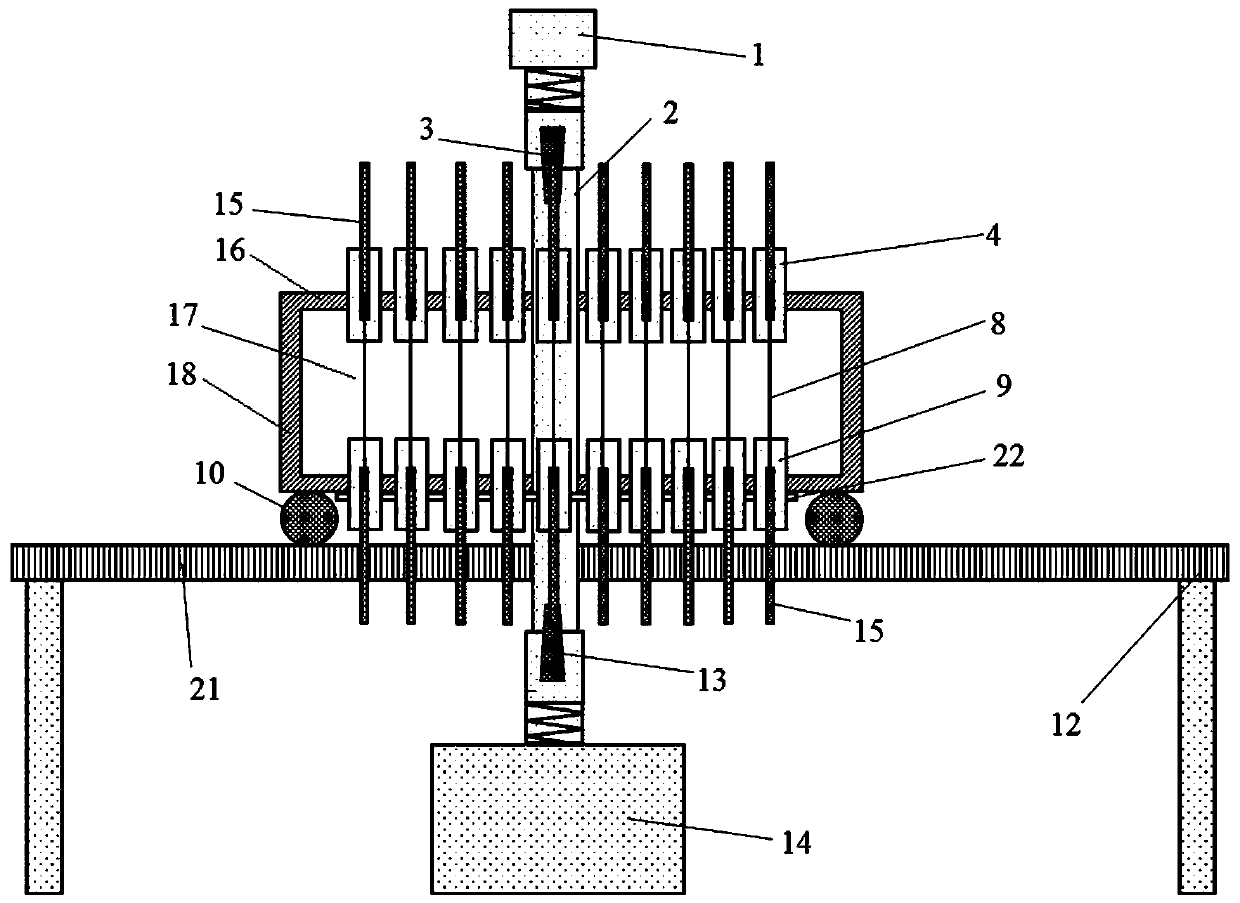

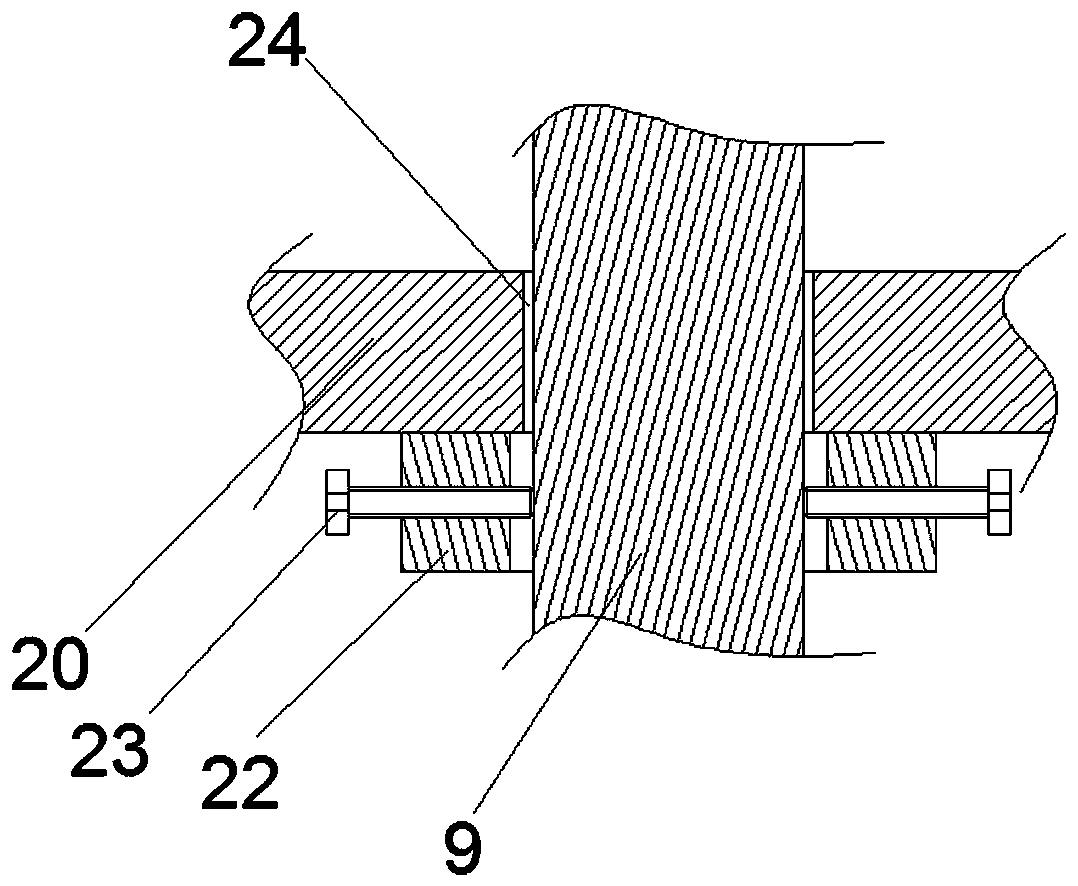

[0018] An example of a tensile test apparatus such as Figure 1~3 Shown: including heating device, tensile testing machine, tensile test piece 17 and large deformation extensometer 7. The tensile testing machine is a conventional tensile testing machine for steel bars, which includes a base 14, on which four columns 2 are arranged, and a beam 1 that can move up and down is equipped with a guiding movement on the column 2. The loading head connected with the reinforcing bar, in the present embodiment, the loading head on the beam is called the upper loading head 3, and the loading head on the base is called the lower loading head 13, wherein the lower loading head is driven by the loading mechanism, in the present embodiment The loading mechanism is a vertically arranged loading cylinder. The upper loading head and the lower loading head belong to the prior art, and will not be described in detail here.

[0019] The heating device includes a heating furnace support 12 and a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com