Standardized production method for improving cigarette mainstream smoke index

A technology for mainstream smoke and indicators of cigarettes, applied in electrical program control, program control, comprehensive factory control, etc., can solve the problems of unsatisfactory optimization results, consuming a lot of manpower, material resources and time, and achieves breakthroughs in limitations and comprehensiveness. Strong, blank-filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for improving the standardized production of cigarette mainstream smoke indicators, comprising the steps of:

[0043] Step (1), select the mainstream smoke index of the cigarette to be improved:

[0044] Select the mainstream smoke index R of the cigarette to be promoted, and the mainstream smoke index R of the cigarette to be promoted is the amount of tar;

[0045] Step (2), sampling:

[0046] Sampling is carried out in this factory and other cigarette manufacturers, take cigarettes of the same specifications, record a total of N types of cigarettes, N≥10; take multiple batches for each type, and record the index R design value of each cigarette and its index R control method; among them, the sampling in this factory is to take the cigarette whose index R is to be raised;

[0047] Step (3), detection:

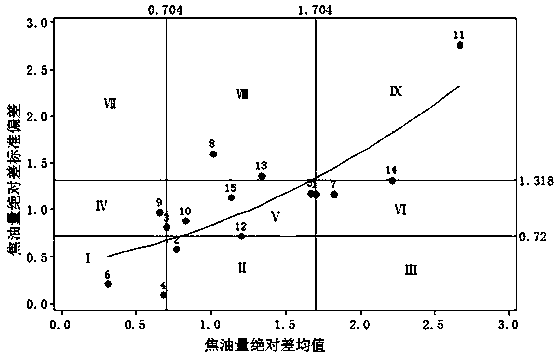

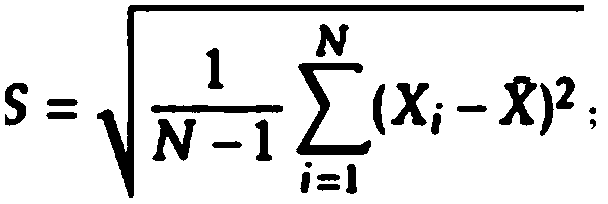

[0048] The index R of the cigarettes taken in step (2) is detected to obtain the measured value of each batch of index R of each kind of cigarette; The mea...

Embodiment 2

[0058] A method for improving the standardized production of cigarette mainstream smoke indicators, comprising the steps of:

[0059] Step (1), select the mainstream smoke index of the cigarette to be improved:

[0060] Select the mainstream smoke index R of the cigarette to be improved, and the mainstream smoke index R of the cigarette to be improved is the amount of CO;

[0061] Step (2), sampling:

[0062] Sampling is carried out in this factory and other cigarette manufacturers, take cigarettes of the same specifications, record a total of N types of cigarettes, N≥8; take 7 batches for each type, and record the index R design value of each cigarette and its index R control method; among them, the sampling in this factory is to take the cigarette whose index R is to be raised;

[0063] Step (3), detection:

[0064] The index R of the cigarettes taken in step (2) is detected to obtain the measured value of each batch of index R of each kind of cigarette; The mean of all ...

Embodiment 3

[0086] A method for improving the standardized production of cigarette mainstream smoke indicators, comprising the steps of:

[0087] Step (1), select the mainstream smoke index of the cigarette to be improved:

[0088] Select the mainstream smoke index R of the cigarette to be improved, and the mainstream smoke index R of the cigarette to be improved is the amount of nicotine;

[0089] Step (2), sampling:

[0090] Sampling is carried out in this factory and other cigarette manufacturers, take cigarettes of the same specifications, record a total of N types of cigarettes, N≥8; take 10 batches for each type, and record the index R design value of each cigarette and its index R control method; among them, the sampling in this factory is to take the cigarette whose index R is to be raised;

[0091] Step (3), detection:

[0092] The index R of the cigarettes taken in step (2) is detected to obtain the measured value of each batch of index R of each kind of cigarette; The mean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com